Essential Components of a Vehicle: A Breakdown of Basic Car Parts

By:Admin

Basic Car Parts

When it comes to vehicles, there are numerous components that work together to ensure the smooth and efficient operation of a car. These basic car parts are essential for the functionality of any vehicle and play a crucial role in the safety and performance of the automobile. Below are some of the most fundamental car parts that are essential for the proper functioning of a vehicle.

Engine: The engine is considered the heart of the vehicle, as it is responsible for generating power and propelling the car. It converts fuel into mechanical energy, which drives the vehicle and its components. The engine consists of various parts, including the pistons, crankshaft, camshaft, and cylinder head, all of which work together to ensure the smooth operation of the engine.

Transmission: The transmission is another vital component of a vehicle, as it is responsible for transferring power from the engine to the wheels. It allows the driver to control the speed and direction of the vehicle by shifting gears. A typical transmission system consists of gears, clutches, and a gearbox, all of which work together to provide the necessary power and torque to the wheels.

Braking System: The braking system is crucial for the safety of the vehicle and its occupants. It allows the driver to slow down or stop the vehicle when necessary. The main components of the braking system include the brake pedal, brake lines, brake calipers, and brake pads. These parts work together to apply friction to the wheels, slowing down the vehicle and bringing it to a stop.

Suspension System: The suspension system plays a significant role in providing a smooth and comfortable ride for the passengers. It consists of various components, including the shocks, struts, springs, and control arms, all of which work together to absorb shocks and vibrations from the road, thereby providing stability and control to the vehicle.

Electrical System: The electrical system of a vehicle is responsible for providing power to various components, including the lights, radio, and other accessories. It consists of the battery, alternator, starter motor, and various wiring and connectors, all of which work together to ensure the proper functioning of the electrical components of the vehicle.

Exhaust System: The exhaust system is responsible for expelling gases from the engine and reducing harmful emissions. It consists of various components, including the exhaust manifold, catalytic converter, and muffler, all of which work together to channel exhaust gases away from the engine and reduce noise and emissions.

[Company] is dedicated to manufacturing high-quality and reliable components for various vehicles, including engines, transmissions, braking systems, suspension systems, electrical systems, and exhaust systems. The company's commitment to quality and excellence makes it a preferred choice for automotive manufacturers and car owners worldwide.

With a strong focus on innovation and continuous improvement, [Company] is constantly striving to develop and produce advanced car parts that meet the highest standards of safety, reliability, and performance. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that every component produced meets the strictest industry standards and regulations.

In conclusion, basic car parts are essential for the functionality and performance of any vehicle. As a leading manufacturer of automotive components, [Company] is dedicated to producing high-quality and reliable parts that ensure the safety, reliability, and performance of vehicles worldwide. With its focus on innovation and quality, the company continues to lead the industry and provide customers with the best automotive parts for their vehicles.

Company News & Blog

Hood Car Parts: Quality Components for Your Vehicle Needs

Title: Hood Car Parts Expands Its Horizon with Innovative Solutions in the Automotive AftermarketIntroduction:In a competitive landscape where innovation and quality reign supreme, Hood Car Parts has emerged as a leading player in the automotive aftermarket industry. With an extensive range of cutting-edge products and a commitment to customer satisfaction, the company has successfully built a reputation as a reliable and trusted partner for car enthusiasts and repair professionals alike. As Hood Car Parts continues its journey of growth and expansion, we explore their innovative solutions that are shaping the future of the automotive industry.1. Diverse Product Portfolio:Hood Car Parts prides itself on offering a wide array of high-quality automotive components, ranging from hoods and doors to mirrors and bumpers. These essential parts are carefully crafted to fit seamlessly into various makes and models, ensuring an optimal fit and superior performance. The company's dedication to providing OEM (Original Equipment Manufacturer) standard parts ensures that customers can rely on Hood Car Parts for their car restoration or repair needs.2. Innovative Technological Advancements:Embracing the latest advancements in technology, Hood Car Parts incorporates cutting-edge features into its products, enhancing functionality and overall user experience. From advanced safety features to intelligent design elements, the company's offerings are designed with a forward-thinking mindset. By leveraging state-of-the-art manufacturing processes and materials, Hood Car Parts ensures durability and longevity, setting them apart from their competitors.3. Commitment to Sustainability:In an era where environmental consciousness is paramount, Hood Car Parts recognizes its responsibility towards sustainable practices. The company actively seeks eco-friendly alternatives and materials to reduce its carbon footprint while maintaining superior product quality. By engaging in responsible sourcing and recycling programs, Hood Car Parts aligns itself with the evolving needs of modern consumers and the growing demand for environmentally-friendly solutions.4. Streamlined Distribution Network:Hood Car Parts has established an efficient and robust distribution network that spans across multiple regions. With strategically located warehouses and supply centers, the company ensures prompt and reliable delivery of its products to customers worldwide. By employing advanced logistics solutions and partnering with trusted transport providers, Hood Car Parts can meet customer demands efficiently, fostering long-standing relationships with clients and repair professionals alike.5. Embracing Digital Transformation:Recognizing the power and convenience of online platforms, Hood Car Parts has invested significantly in establishing a strong online presence. The company's user-friendly website offers a seamless purchasing experience, providing customers with detailed product information, compatibility specifications, and extensive support resources. Furthermore, Hood Car Parts actively engages with customers through various digital channels, including social media platforms and customer support forums, fostering open communication and strengthening brand loyalty.6. Customer-Centric Approach:At the core of Hood Car Parts' success lies a strong commitment to customer satisfaction. The company takes great pride in its responsive and knowledgeable customer support team, who are readily available to address queries and provide technical assistance. By actively listening to customer feedback, Hood Car Parts continuously improves its product offerings and services, ensuring that every interaction with the brand is met with professionalism and exceptional service.Conclusion:As Hood Car Parts continues to reshape the automotive aftermarket industry with its forward-thinking approach, the company solidifies its position as an industry leader. With an extensive product portfolio, innovative technological advancements, commitment to sustainability, streamlined distribution network, and digital transformation initiatives, Hood Car Parts offers a comprehensive and customer-centric solution for car enthusiasts and repair professionals worldwide. By consistently exceeding customer expectations and embracing the latest industry trends, Hood Car Parts remains at the forefront of the automotive aftermarket industry, driving innovation and shaping the future of automotive repair and restoration.

Top 5 Engine Parts You Need to Know for Maintaining Your Car

Automobile engines are undoubtedly the most complex machinery that powers our vehicles. These engines consist of several parts that work together to produce motion and energy required to keep the vehicle moving. One of the global leaders in manufacturing automobile engine parts is a company that is known for its innovative technology and exceptional quality.Founded in X, the company has been in business for over X years and has established itself as a reputable and trustworthy provider of automobile engine parts. With advanced technology and state-of-the-art manufacturing facilities, the company has been producing high-quality engine components that are used by many of the world's leading automobile manufacturers.The company specializes in producing engine valves, valve guides, tappets, and other related components that are integral to the operation of an engine. These parts are manufactured using only the highest quality raw materials, which are carefully selected to ensure reliability, durability, and longevity. The company follows strict quality control processes to ensure the parts they produce meet the highest standards and perform exceptionally well under all conditions.One of the key strengths of the company is its experienced and skilled workforce. The company employs some of the most talented engineers, designers, and technicians in the industry who are capable of developing innovative and cutting-edge technology. The company invests heavily in research and development, which enables it to introduce new and improved engine components year after year.In addition to its advanced technological capabilities, the company has a global reach. It has a strong presence in many countries around the world, with a focus on manufacturing and supplying engine components that meet local regulations and standards. The company's global network ensures that its engine components are readily available wherever they are needed, making it an ideal partner for companies operating in different regions.The company's success can be attributed to its unwavering commitment to quality and customer satisfaction. Its ability to consistently deliver high-quality engine components has made the company a preferred supplier for many leading automobile manufacturers. The company has also won several awards and accolades for its exceptional products and services.Looking ahead, the company is well-positioned for further growth and expansion. Its strong R&D capabilities and global reach will enable it to continue developing new and improved engine components that meet the evolving needs of the automobile industry. The rising demand for advanced engine components that are energy-efficient and environmentally friendly presents an exciting opportunity for the company to continue making a significant impact in the industry.In conclusion, the company's reputation for producing high-quality automobile engine parts is unrivaled. Its commitment to innovation, reliability, and customer satisfaction has made it a trusted partner for leading automobile manufacturers around the world. As the industry continues to evolve and demand for advanced engine components increases, the company is well-positioned to maintain its leadership position and continue driving innovation in the field.

Discover the Key Components of Car Wheels: A Comprehensive Guide

Car Wheel Components, a leading manufacturer of high-quality automotive components, has recently emerged as a popular choice for many vehicle owners worldwide. The company specializes in designing and manufacturing a wide range of car parts, including wheels, rims, hubcaps, and other related components. With its commitment to excellence, Car Wheel Components has established itself as a reliable supplier of premium-quality products that are built to last.At the core of Car Wheel Components’ success is its unwavering focus on customer satisfaction. The company understands that its products are essential to the safety and performance of a vehicle, and as such, places great emphasis on ensuring that every item that leaves its factories meets the highest quality standards. As a result, the company has gained a reputation for delivering dependable, durable, and stylish car parts that meet the specific needs of its customers.One of the key elements of Car Wheel Components’ success is its desire to innovate. The company has always been at the forefront of developing new technologies and manufacturing techniques, which has led to the introduction of several revolutionary products. For example, the company’s proprietary alloy wheel technology has become a benchmark for quality and performance in the automotive industry. These wheels are lighter and stronger than traditional steel wheels, which improves vehicle handling, fuel efficiency, and overall performance.In addition to its focus on innovation, Car Wheel Components has always been committed to sustainability. The company recognizes the impact that its products can have on the environment and takes measures to minimize this impact. For example, the company has implemented a recycling program that ensures the responsible disposal of used materials. It also utilizes energy-efficient technologies to reduce its carbon footprint and improve its environmental performance.Car Wheel Components’ success can also be attributed to its highly skilled and dedicated team of professionals. The company employs some of the best engineers, designers, and technicians in the industry, all of whom are committed to delivering the highest quality products and services. Car Wheel Components’ team works tirelessly to develop new designs and manufacturing techniques to keep up with the ever-changing demands of the automotive market.Looking ahead, Car Wheel Components is well-positioned to capitalize on the trends shaping the automotive industry. With the demand for electric and hybrid vehicles set to rise in the coming years, the company is already developing new technologies and products that cater to this market. It is also investing in research and development to explore the possibilities of new materials, manufacturing techniques, and other innovations that will shape the future of automotive components.In conclusion, Car Wheel Components is a company that has established itself as a leader in the automotive industry. With its commitment to innovation, quality, and sustainability, the company has gained the trust and loyalty of its customers around the world. As the company looks to the future, it is poised to continue its growth and success by developing new products, technologies, and partnerships that will enable it to remain at the forefront of the industry.

Top Car Parts Every Vehicle Owner Should Know

[Date, Month, Year]: Basic Car Parts: [Company Name] Introduces High-Quality Automotive Components[City, Country] – When it comes to vehicle maintenance and repair, having access to high-quality basic car parts is essential. Whether it's for regular maintenance or a repair job, having reliable parts ensures the safety and performance of the vehicle. In line with this, [Company Name] is proud to introduce a new line of basic car parts designed to meet the needs of car owners and mechanics.[Company Name] has been a leading provider of automotive components for [number] years. With a strong commitment to quality and innovation, the company has earned a reputation for excellence in the industry. The introduction of the new line of basic car parts is a testament to [Company Name]'s dedication to providing customers with the best products available.Among the basic car parts offered by [Company Name] are filters, belts, hoses, gaskets, and spark plugs. These components are essential for the proper functioning of a vehicle and are often replaced during routine maintenance. By offering these parts, [Company Name] aims to make it easier for car owners and mechanics to find the parts they need without compromising on quality.One of the key features of the new line of basic car parts is their durability and reliability. [Company Name] understands the importance of using high-quality materials to ensure that the parts can withstand the rigors of daily use. Whether it's the engine air filter, the fuel filter, or the oil filter, customers can trust that these parts will perform optimally and contribute to the overall efficiency of the vehicle.In addition to durability, [Company Name]'s basic car parts are designed for easy installation. Recognizing that time is of the essence when it comes to vehicle maintenance and repair, the company has ensured that its parts are user-friendly and can be installed with ease. This feature is especially beneficial for mechanics who are tasked with completing multiple jobs in a day.Furthermore, [Company Name] takes pride in the affordability of its basic car parts. While the components are of the highest quality, the company has kept the prices competitive to make them accessible to a wide range of customers. This pricing strategy underscores [Company Name]'s commitment to serving the needs of its customers and prioritizing their satisfaction.To ensure that customers have a seamless experience, [Company Name] has made its new line of basic car parts available through a variety of channels. Whether it's through the company's website, authorized dealers, or auto parts stores, customers can easily access the components they need. This widespread availability is a reflection of [Company Name]'s dedication to making its products as accessible as possible.In conclusion, the introduction of [Company Name]'s new line of basic car parts marks an important milestone for the company and its customers. By offering high-quality, durable, and affordable components, [Company Name] is set to make a significant impact in the automotive industry. Whether it's a car owner in need of a replacement part or a mechanic looking for reliable components, [Company Name]'s basic car parts are poised to meet their needs and exceed their expectations. With this new line of products, [Company Name] continues to demonstrate its commitment to excellence and innovation in the automotive market.For media inquiries or more information about [Company Name]'s new line of basic car parts, please contact:[Contact Information]

Different Varieties of Closed Die Forging Techniques

In the world of manufacturing, forging is an essential process that transforms raw materials into high-quality, sturdy products. Closed die forging is one of the most popular forms of forging, which involves the shaping of metal parts by pressing them between two dies. This process produces parts that are exceedingly strong and durable, with high resistance to wear and tear.Closed die forging is also known as impression die forging or drop forging. It is a process that involves heating metal to a temperature where it is malleable and pressing it between a pair of dies to form the intended shape. The dies contain pre-determined impressions of the desired shape of the metal part. It is the repetitive and controlled pressing of the heated metal that eventually yields the final product.One of the best things about the closed die forging process is that it allows for intricate designs and shapes to be created with a high level of precision. It is possible to create parts with complex geometries, including shapes with internal cavities. This is achieved by creating separate dies, which can be combined to form the desired shape of the final component.The closed die forging process can be performed using different types of dies, depending on the complexity of the part being manufactured. Some of the most common types of closed die forging are upset forging, roll forging, press forging, and hot forging.Upset forging is a type of closed die forging that involves the reshaping of the metal at its head. It is typically used to manufacture bolts, screws, and rivets.Roll forging, on the other hand, involves the use of rollers to press the metal into the required shape. This process is typically used to manufacture gears and shafts.Press forging is a more modern form of closed die forging that utilizes mechanical presses to apply pressure to the metal. It is a more automated process that produces high-quality, precision components in large quantities.Finally, hot forging is a process that involves the heating of the metal to very high temperatures before it is pressed between the dies. This process is used to manufacture complex components that require precise shaping.One company that has been at the forefront of closed die forging is [brand name removed]. [Brand name removed] has been providing high-quality closed die forging services for over 30 years, catering to a wide range of industries such as aerospace, automotive, defense, and energy.With a team of expert engineers and state-of-the-art equipment, [Brand name removed] is able to provide its customers with an extensive range of closed die forging services. From forging single and multiple components to producing complex assemblies, [Brand name removed] is a one-stop-shop for all your forging needs.The company has a wide range of forging capabilities, including upset forging, roll forging, press forging, and hot forging. No matter how complex the component, [Brand name removed] is able to deliver high-quality forgings that meet or exceed customer expectations.To ensure the highest quality components, [Brand name removed] employs a rigorous quality control process. Every component produced goes through a series of tests and inspections to ensure that it meets the required specifications. The company is also ISO 9001 certified, which is a testament to its commitment to quality and customer satisfaction.In addition to providing high-quality forgings, [Brand name removed] also offers value-added services such as machining, heat treating, and surface finishing. This ensures that customers receive finished components that are ready to be integrated into their products, saving them time and money.In conclusion, closed die forging is a critical process in the manufacturing industry, and [Brand name removed] has proven to be an expert in this field. With its extensive range of forging capabilities, rigorous quality control process, and value-added services, [Brand name removed] is a preferred choice for customers seeking high-quality forgings.

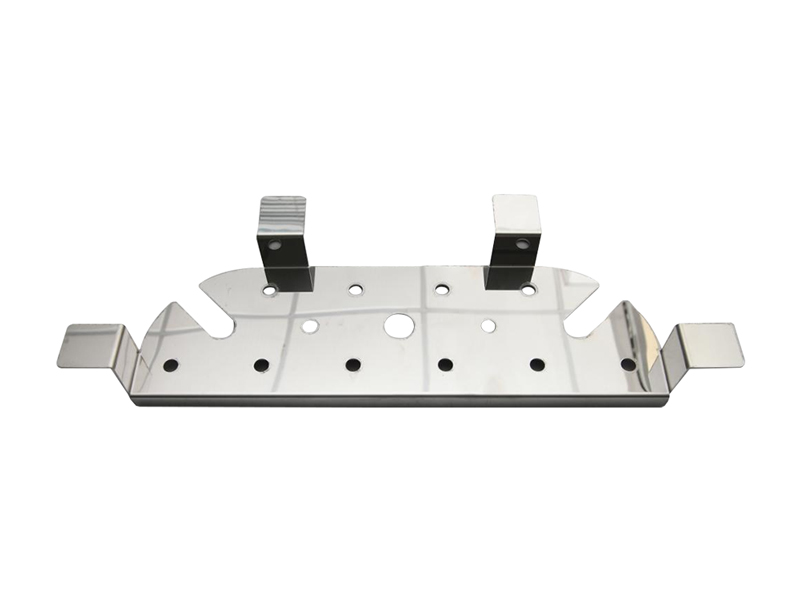

Exploring the Growing Demand for Automotive Sheet Metal in the Industry

Title: Automotive Sheet Metal: Revolutionizing the Automotive IndustryIntroduction:The automotive industry is undergoing a transformation with advancements in technology and growing consumer demands for efficient and sustainable vehicles. Automotive sheet metal, a key component in this evolution, is driving innovations in automotive manufacturing. In this article, we will explore the significance of automotive sheet metal and its role in shaping the future of the industry.I. Understanding Automotive Sheet Metal Automotive sheet metal refers to the thin and durable metal sheets used in various parts of a vehicle, including body panels, chassis, and internal components. It plays a crucial role in providing structural integrity, safety, and visual appeal to automobiles. II. The Advantages of Automotive Sheet Metal 1. Lightweight and High Strength: Automotive sheet metal is known for its lightweight yet high-strength properties, making it ideal for lightweight vehicle designs. This not only enhances fuel efficiency but also improves vehicle performance and handling.2. Design Flexibility: The malleability and formability of automotive sheet metal allow for intricate designs, giving automakers the freedom to craft vehicles with sleek and aerodynamic exteriors. This results in enhanced aerodynamic efficiency, reducing air resistance and improving overall vehicle efficiency.III. Growing Popularity of Aluminum Sheet Metal 1. Aluminum Revolution: With its exceptional strength-to-weight ratio, aluminum sheet metal has become increasingly popular in the automotive industry. Its use not only reduces vehicle weight but also improves fuel efficiency and enhances overall performance. Aluminum's corrosion resistance properties make it an ideal choice for various automotive applications.2. Advancements in Aluminum Sheet Metal: Automotive sheet metal manufacturers are constantly innovating to improve the properties of aluminum sheets. Introducing advanced alloys, they have successfully enhanced strength and reduced weight, further propelling the adoption of aluminum in automobile manufacturing.IV. Steel Sheet Metal and its Significance 1. Steel's Strength and Durability: Steel sheet metal has long been the primary material in automotive manufacturing due to its exceptional strength, durability, and affordability. It offers excellent structural rigidity and crashworthiness, ensuring passenger safety in the event of a collision.2. Advanced High-Strength Steel (AHSS): Technological advancements have led to the development of Advanced High-Strength Steel (AHSS), which combines increased strength with reduced weight. AHSS is now widely used in automotive sheet metal applications, providing automakers with cost-effective yet highly secure options.V. Impact on Manufacturing Processes 1. Enhanced Efficiency: The use of automotive sheet metal has led to improved manufacturing processes with increased automated solutions. These advancements, such as robotic welding and laser cutting, have reduced production time and increased precision, ultimately leading to higher productivity and cost-effectiveness.2. Environmental Considerations: Automotive sheet metal plays a crucial role in making vehicles more sustainable. Aluminum and steel are highly recyclable materials, and their widespread use in automotive manufacturing contributes to reducing the industry's carbon footprint and promoting a circular economy.VI. Conclusion Automotive sheet metal is an essential component in the construction of modern vehicles, fostering lightweight, safe, and environmentally friendly automobile designs. With the growing demand for electric vehicles and increasing emphasis on sustainability, automotive sheet metal will continue to shape the future of the automotive industry.As automakers focus on developing new technologies and sustainable solutions, the significant advancements in automotive sheet metal stand as a testament to the industry's commitment to innovation and progress. The ongoing research and development efforts in this field promise an exciting future with more efficient, safer, and visually appealing automobiles.

Optimize Your Vehicle's Performance with High-Quality Shaft Car Parts

Shaft Car Part Announces New Product Innovation[Company Name], a leading automotive parts manufacturer and supplier, is thrilled to announce the launch of their latest innovative product, the Shaft Car Part. This groundbreaking development is set to revolutionize the automotive industry, providing car owners with a reliable and efficient solution for their vehicle's performance.With an established reputation for excellence and a commitment to delivering quality products, [Company Name] is known for its dedication to customer satisfaction. Leveraging years of industry expertise, the company continues to stay ahead of the competition by consistently introducing new and cutting-edge products.The Shaft Car Part is set to make its mark with its advanced design and state-of-the-art technology. Manufactured using high-quality materials and precision engineering, this innovative product offers car owners the promise of improved performance, enhanced durability, and a smoother driving experience.Designed to ensure optimal power transmission and reliability, the Shaft Car Part is built to withstand the rigorous demands of everyday use. Its robust construction enhances the vehicle's drivetrain system, resulting in increased torque and improved acceleration. Additionally, the part's enhanced durability minimizes the risk of breakdowns and costly repairs, providing car owners with peace of mind and long-lasting performance.One of the key features of the Shaft Car Part is its compatibility with a wide range of car models and makes. This universal adaptability ensures that car owners can benefit from this innovative product regardless of the vehicle they own. This flexibility further demonstrates [Company Name]'s commitment to providing accessible solutions for all customers, regardless of their automotive preferences.Furthermore, the Shaft Car Part boasts an easy installation process, making it ideal for both professional mechanics and car enthusiasts. Its user-friendly design allows for hassle-free integration into the existing vehicle system, reducing downtime and minimizing labor costs. This accessibility is especially valuable to customers who prefer to work on their own cars or those who rely on quick and efficient servicing.The launch of the Shaft Car Part reinforces [Company Name]'s ongoing commitment to research and development. The company invests heavily in state-of-the-art facilities and employs a dedicated team of engineers and technicians to ensure continuous product improvement and innovation. By actively listening to customer feedback and striving for excellence in their products, [Company Name] aims to meet and exceed the ever-evolving needs of the automotive industry."We are incredibly excited to introduce the Shaft Car Part to the market," said [Company Name]'s CEO. "This is a significant milestone for us, and it demonstrates our commitment to delivering exceptional automotive parts that enhance the driving experience. Our team has worked tirelessly to develop a product that not only meets the highest quality standards but also offers increased performance and reliability to our valued customers."Customers can expect to find the Shaft Car Part available for purchase at authorized dealers and online retailers starting next month. [Company Name] also offers a comprehensive warranty program for added customer assurance.In conclusion, [Company Name]'s announcement of the Shaft Car Part showcases their commitment to innovation and customer satisfaction. With its advanced design, superior performance, and universal compatibility, it is set to significantly impact the automotive industry. As car owners strive to optimize their driving experience, [Company Name] continues to be the go-to destination for cutting-edge automotive solutions.

High-Quality Aluminium Casting Die for Precision Manufacturing

Aluminium Casting Die Technology Revolutionizes Manufacturing at {}In the world of manufacturing, precision and quality are paramount. With the advancement of technology, the process of aluminium casting has evolved dramatically, thanks to cutting-edge Aluminium Casting Die technology. This revolutionary technology has not only improved the quality of aluminium products but has also significantly streamlined the manufacturing process, ultimately benefiting companies like {}.Founded in 1985, {} has been a leading force in the manufacturing industry, specializing in the production of high-quality aluminium products. With a strong emphasis on innovation and quality, the company has constantly sought ways to improve its manufacturing processes and deliver the best products to its customers. The introduction of Aluminium Casting Die technology has been a game-changer for the company, enabling it to further enhance its capabilities and achieve new heights of excellence in aluminium casting.Aluminium Casting Die technology has revolutionized the manufacturing process by allowing for the production of intricate and complex aluminium parts with unmatched precision. The technology utilizes advanced die-casting techniques to create moulds with extreme accuracy, resulting in highly detailed and flawless aluminium products. This level of precision has allowed {} to expand its product offerings and cater to a wider range of industries, including automotive, aerospace, and electronics.One of the key advantages of Aluminium Casting Die technology is its ability to produce aluminium parts with consistent quality and dimensional accuracy. This not only ensures that each part meets the highest standards but also significantly reduces wastage and rework, leading to cost savings for the company. With the implementation of this technology, {} has been able to improve its manufacturing efficiency and deliver products to its customers in a more timely and cost-effective manner.Moreover, the use of Aluminium Casting Die technology has enabled {} to achieve greater design flexibility in its manufacturing processes. The technology allows for the production of complex geometries and thin-walled sections, opening up new possibilities for product innovation and customization. This has empowered {} to collaborate with its customers more closely, offering tailored solutions to meet their specific needs and requirements.In addition to its technical advantages, Aluminium Casting Die technology also aligns with {}'s commitment to sustainability. The technology promotes the use of recycled aluminium, reducing the environmental impact of the manufacturing process. By embracing this environmentally friendly approach, {} is not only contributing to a greener planet but also catering to the growing demand for sustainable products in the market.As the industry continues to evolve, {} remains at the forefront of innovation, leveraging the latest technologies to stay ahead of the competition. The integration of Aluminium Casting Die technology has not only enhanced the company's manufacturing capabilities but has also positioned it as a leader in the field of aluminium casting. With a continued focus on quality, efficiency, and sustainability, {} is poised to further elevate its position in the market and continue to provide exceptional aluminium products to its customers.In conclusion, the introduction of Aluminium Casting Die technology has been a game-changer for {} and the manufacturing industry as a whole. By embracing this cutting-edge technology, {} has been able to significantly improve its manufacturing processes, enhance product quality, and expand its offerings to a wider range of industries. As the company continues to push the boundaries of innovation, it is clear that Aluminium Casting Die technology will play a pivotal role in shaping the future of manufacturing at {} and beyond.

Discover the Key Aspects of Aluminum Billet Casting for Efficient Manufacturing

Aluminum Billet Casting Company Pioneering Sustainability EffortsAluminum Billet Casting (ABC), an industry-leading company in aluminum casting technology, has recently been recognized for their innovations in sustainability efforts. ABC is committed to meeting the growing demand for green manufacturing practices and reducing its impact on the environment. The company believes in making progress by working alongside clients and suppliers to create a sustainable business model.ABC has initiated innovative measures to ensure that their production process is environmentally friendly and energy-efficient. These include the installation of the state-of-the-art technological equipment, sustainable practices and management systems, fostering worker safety, and embracing a sense of social responsibility. Through environmental sustainability efforts, ABC meets the growing demand for safe and sustainable production methods that align with global standards.With a focus on environmental preservation, ABC has put in place many initiatives that help protect the planet. The company actively recycles materials to minimize waste and reduce the pressure on forests and landfills. All the materials used in the casting process are sourced from certified suppliers who follow sustainable production methods. Additionally, ABC invests in renewable energy and efficiency measures to minimize their carbon footprint and reduce their energy bills.To promote worker safety and health, ABC has undertaken several safety initiatives that ensure employees’ optimum well-being. The company has developed a comprehensive safety program that educates workers about safety protocols, manages risks, and estimates potential hazards. The program provides in-depth training on safety procedures, which in turn ensures safety for workers and the plant.ABC also takes its social responsibility to heart. The company contributes to charitable initiatives and actively supports local communities. ABC volunteers in various social development programs to give back to the community. These activities range from health and education programs to supporting community initiatives like sports and youth events. The company believes that such contributions play an essential role in driving change and building goodwill in the communities they serve.The ABC team is committed to raising awareness of environmental challenges and inspiring others to adopt sustainable practices in their daily lives. The company is dedicated to working with suppliers and clients to create a more sustainable world. They are continuously exploring innovative ways to reduce the environmental impact of their manufacturing processes.ABC has established itself as a reliable and professional aluminum casting company, with a broad and diverse client base. The company has been able to achieve an outstanding reputation by combining quality products with excellent customer service. ABC has earned the trust of its clients, which is reflected in the long-term partnerships they have built.With a robust commitment to sustainability and innovations in environmentally friendly production methods, ABC is leading the change in the casting industry. The company continues to invest in state-of-the-art technology, machinery, and facilities, to provide their clients with high-quality products while reducing their environmental impact.According to the CEO, “We believe that every business has a responsibility to minimize its impact on the environment and the community it serves. Our vision is to be recognized as a leader in sustainability, and we will continue to explore innovative ways to make our production processes environmentally friendly. We will continue to cultivate a culture that values worker safety, environmental responsibility, social contributions, and customer satisfaction.”In conclusion, Aluminum Billet Casting (ABC) is an industry leader in aluminum casting technology with a focus on sustainability and environmental responsibility. The company has implemented many initiatives to minimize its environmental impact while providing safe and quality products to its clients. ABC continues to invest in innovative technology and sustainable practices, putting itself ahead of the competition. The company's commitment to social responsibility and community development sets it apart from other players in the industry. ABC is indeed a model for companies looking to adopt sustainable practices in the manufacturing industry.

Common Car Part: Everything You Need to Know about Electronic Control Modules

The car industry is constantly evolving with new technological advancements and innovations. One key component of modern vehicles is the Engine Control Module (ECM), which plays a crucial role in monitoring and controlling the engine's functions. As vehicles become more complex and sophisticated, the demand for reliable ECM car parts has increased significantly.In response to this growing demand, {Company Name} has emerged as a leading provider of high-quality ECM car parts for a wide range of vehicle makes and models. The company has built a solid reputation for delivering top-notch products that meet the highest standards of quality and reliability. With a commitment to innovation and customer satisfaction, {Company Name} has quickly become a trusted name in the automotive industry.One of the main reasons behind the company's success is its dedication to research and development. {Company Name}'s team of skilled engineers and technicians are constantly working to improve and enhance their ECM car parts, ensuring that they meet the evolving needs of the market. By staying at the forefront of technological advancements, the company is able to provide cutting-edge solutions that keep vehicles running smoothly and efficiently.Furthermore, {Company Name} takes pride in its state-of-the-art manufacturing facilities, which are equipped with the latest machinery and advanced production techniques. This allows the company to maintain strict quality control throughout the manufacturing process, resulting in ECM car parts that are durable, reliable, and performance-driven. Additionally, {Company Name} is committed to sustainability and environmentally friendly practices, ensuring that its operations have a minimal impact on the environment.As a customer-centric company, {Company Name} places a strong emphasis on providing excellent service and support to its clients. Whether it's assisting with product selection, offering technical advice, or providing after-sales assistance, the company's dedicated team is always ready to go the extra mile to ensure customer satisfaction. This level of commitment has earned {Company Name} a loyal customer base that continues to grow.The range of ECM car parts offered by {Company Name} is comprehensive, covering a wide spectrum of vehicle applications. From compact cars to heavy-duty trucks, the company's products are designed to meet the specific requirements of different vehicle types. With a focus on performance, durability, and compatibility, {Company Name} ensures that its ECM car parts deliver outstanding results in any driving condition.In addition to providing OEM (Original Equipment Manufacturer) parts, {Company Name} also offers custom solutions for clients with unique needs or specifications. This versatility and flexibility set the company apart from its competitors, allowing it to cater to a diverse clientele with varying demands. Whether it's a small-scale order or a large-scale production run, {Company Name} has the capabilities to deliver bespoke ECM car parts that meet the highest standards.Looking ahead, {Company Name} is poised to continue its expansion and growth within the automotive industry. By staying true to its core values of quality, innovation, and customer satisfaction, the company is well-positioned to capture new opportunities and establish itself as a market leader in the ECM car parts sector. With a strong focus on product excellence and customer service, {Company Name} is set to drive the future of automotive technology.