Top Front Car Parts for Sale: Bumpers, Grilles, and More

By:Admin

[City, State] - [Company Name], a leading manufacturer in the automotive industry, is proud to announce the release of its latest innovation in car front parts. The new front parts are designed to enhance the functionality, durability, and aesthetics of vehicles, providing drivers and car enthusiasts with an unparalleled experience on the road.

With a commitment to quality and excellence, [Company Name] has been a key player in the automotive industry for [number] years. Their passion for innovation and dedication to customer satisfaction have earned them a solid reputation as a reliable and trusted provider of automotive parts and accessories. The company's state-of-the-art production facilities and cutting-edge technology enable them to stay ahead of the competition and continually raise the bar for industry standards.

The new line of car front parts is a testament to [Company Name]'s unwavering commitment to pushing the boundaries of innovation in the automotive industry. The parts are meticulously designed and engineered to meet the highest standards of quality and performance, ensuring that they deliver exceptional value to customers. Whether it's a replacement part or an upgrade, [Company Name]'s front parts are set to revolutionize the driving experience for car owners.

One of the key features of the new front parts is their advanced materials and construction. [Company Name] has leveraged their expertise in materials science to develop parts that are not only lightweight and durable but also resistant to corrosion and wear. This ensures that the parts can withstand the rigors of daily driving and maintain their pristine appearance for years to come.

In addition to their superior build quality, the front parts are also designed to improve the aerodynamics and performance of vehicles. With careful consideration to airflow and design, [Company Name] has crafted parts that seamlessly integrate with the vehicle's body, reducing drag and optimizing fuel efficiency. This not only enhances the driving experience but also contributes to a more sustainable and eco-friendly operation.

Furthermore, the front parts are available in a variety of styles and finishes, allowing customers to personalize their vehicles to their liking. Whether it's a sleek and sporty look or a bold and aggressive stance, [Company Name]'s front parts offer versatility and customization options to suit different preferences and tastes. Customers can choose from a range of colors and designs to complement their vehicle's aesthetic and make a statement on the road.

To ensure a seamless installation and fit, [Company Name] provides comprehensive support and resources for customers. Their team of experts is readily available to assist with any inquiries and provide guidance on the selection and installation of front parts. Furthermore, the parts are precision-engineered to OEM specifications, guaranteeing compatibility and a perfect fit with popular vehicle models.

With the release of the new front parts, [Company Name] continues to solidify its position as a trailblazer in the automotive industry. Their unwavering commitment to excellence and innovation sets the bar high for competitors and reinforces their status as a go-to provider for high-quality automotive parts and accessories.

Customers and car enthusiasts can look forward to experiencing the unparalleled performance, durability, and aesthetics that [Company Name]'s new car front parts have to offer. As the automotive industry continues to evolve, [Company Name] remains at the forefront, leading the charge with groundbreaking innovations and solutions for drivers worldwide.

Company News & Blog

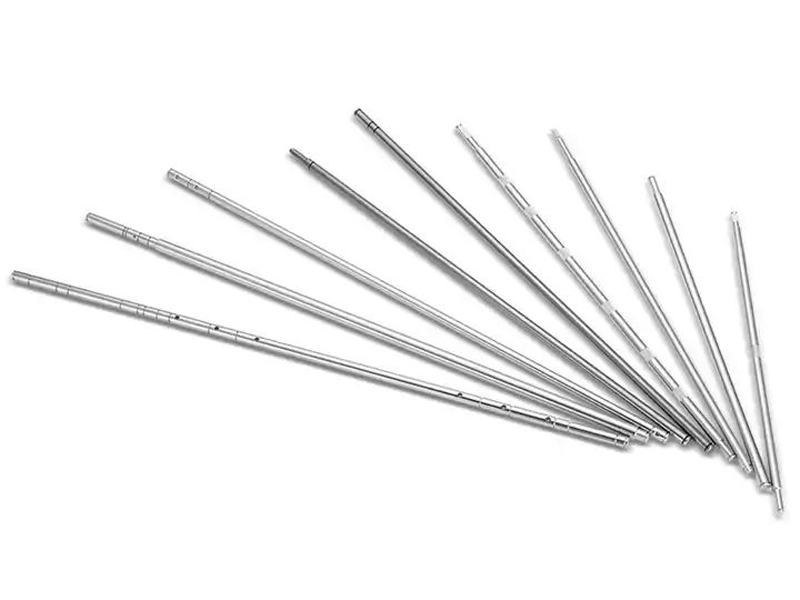

Newly Developed Shaft Car Part Revolutionizes Vehicle Performance

Shaft Car Part, a leading manufacturer of automotive components, has announced the release of their latest innovation in car part technology. The new product is designed to improve the performance and reliability of vehicles, setting a new standard for quality and durability in the automotive industry.Since its establishment, Shaft Car Part has been dedicated to providing top-notch components for car enthusiasts and professionals alike. With a commitment to delivering high-quality products, the company has earned a solid reputation as a reliable and innovative supplier in the automotive market.The new car part is a result of extensive research and development, as well as state-of-the-art manufacturing processes. It boasts cutting-edge technology and advanced engineering, setting it apart from the competition. By leveraging the latest materials and production techniques, Shaft Car Part has created a product that promises to enhance the driving experience for customers."We are thrilled to introduce our latest innovation in car part technology," said the spokesperson for Shaft Car Part. "This new product represents our ongoing dedication to excellence and our relentless pursuit of innovation. We believe it will set a new standard for performance and reliability in the automotive industry."The new car part is designed to improve various aspects of vehicle performance, including efficiency, power, and durability. By upgrading to this new component, customers can expect a smoother and more responsive driving experience, as well as improved fuel economy and reduced engine wear.In addition to its performance benefits, the new car part is also designed with longevity in mind. With a focus on durability and reliability, Shaft Car Part has engineered this product to withstand the rigors of daily driving and deliver consistent, dependable performance over the long term.Shaft Car Part's commitment to quality and innovation is further reflected in their rigorous testing and quality control processes. Before the new car part is released to the market, it undergoes extensive testing to ensure that it meets the company's stringent standards for performance and reliability. This dedication to quality assurance gives customers the peace of mind that they are investing in a product that is built to last.In addition to its technical advancements, the new car part also offers a sleek and modern design that is sure to complement any vehicle. Its aesthetic appeal is a testament to Shaft Car Part's dedication to creating products that not only perform well but also look great.Shaft Car Part's new car part is now available for purchase, and customers can look forward to experiencing the benefits of this cutting-edge technology in their own vehicles. With its focus on performance, reliability, and durability, this product is poised to make a significant impact in the automotive industry and further solidify Shaft Car Part's position as a leader in the market.As the automotive industry continues to evolve, Shaft Car Part remains at the forefront of innovation, constantly pushing the boundaries of what is possible in car part technology. With their latest release, the company has once again demonstrated their commitment to excellence and their ability to deliver products that exceed customer expectations. By setting a new standard for quality and durability, Shaft Car Part is shaping the future of automotive performance and reliability.

Durable High Chrome Steel Castings for Industrial Use

High Chrome Steel Castings have become an essential part in diverse industries, including mining, construction, and energy production. These castings are known for their durability and resistance to wear and tear, making them an ideal choice for heavy-duty applications. {Company}, a leading manufacturer of high-quality steel castings, has been at the forefront of supplying superior products to meet the growing demands of various industries.{Company} has a rich history of expertise in producing high chrome steel castings with a focus on quality, precision, and innovation. With state-of-the-art manufacturing facilities and a team of skilled engineers and technicians, the company has been able to consistently deliver top-notch products that exceed the expectations of its customers. The high chrome steel castings produced by {Company} are widely used in the mining industry for equipment such as crushers, pulverizers, and grinding mills. These castings are specifically designed to withstand the extreme conditions and abrasive materials encountered in mining operations, ensuring reliable performance and extended service life. In the construction industry, {Company}'s high chrome steel castings are sought after for their exceptional strength and resistance to impact and abrasion. These qualities make them suitable for use in cement plants, road construction, and infrastructure development, where reliability and longevity are paramount.Moreover, the energy production sector relies on high chrome steel castings for various applications, including power generation, oil and gas extraction, and renewable energy projects. The ability of these castings to withstand high temperatures, corrosion, and erosion makes them an ideal choice for critical components in power plants, drilling equipment, and renewable energy systems.{Company}'s commitment to quality and customer satisfaction has earned them a stellar reputation in the industry. The company adheres to stringent quality control measures at every stage of the manufacturing process to ensure that each casting meets the highest standards of performance and durability. Furthermore, {Company} places a strong emphasis on research and development to continually improve its products and explore new applications for high chrome steel castings. The company works closely with its clients to understand their specific needs and develop customized solutions that address their unique challenges.In addition to its focus on product excellence, {Company} also prioritizes environmental sustainability and operational safety. The company is dedicated to minimizing its environmental footprint and adheres to strict safety protocols to ensure the well-being of its employees and the communities in which it operates.With a global network of distribution partners and a customer-centric approach, {Company} has been able to serve a wide range of industries in various regions around the world. The company's commitment to delivering reliable, high-performance products has made it a preferred choice for many discerning customers.As the demand for high chrome steel castings continues to grow, {Company} is well-positioned to meet the needs of its customers with its unwavering dedication to quality, innovation, and customer satisfaction. The company's proven track record and industry expertise make it a reliable partner for businesses looking for superior steel casting solutions.In conclusion, {Company} has established itself as a trusted leader in the production of high chrome steel castings, offering unparalleled quality, performance, and reliability. With a focus on excellence and a passion for innovation, the company continues to set new standards in the industry and provide valuable solutions to its customers.

High-Quality Green Sand for Casting Aluminum: A Guide

Green sand for casting aluminum is a sustainable and environmentally friendly alternative that is now available through the innovative efforts of a leading supplier in the industry. The company, with a successful track record of providing high-quality products and services, has introduced this new green sand option to meet the growing demand for eco-friendly solutions in the aluminum casting process.Traditionally, aluminum casting involves the use of sand molds to create the desired shapes and forms. However, the sand used in this process is often bonded with chemicals and resins that can be harmful to the environment and pose health risks to workers. In response to these concerns, the company has developed a proprietary green sand formula that eliminates the need for these harmful additives.The green sand offered by the company is made from natural, sustainable materials that are free from harmful chemicals and resins. This not only makes it safer for the environment and workers but also ensures a cleaner and more sustainable casting process. By providing a greener alternative to traditional sand casting, the company is helping their customers reduce their environmental impact and meet their sustainability goals.In addition to its environmental benefits, the green sand is also designed to deliver superior performance in the aluminum casting process. It offers excellent flowability, compaction, and thermal stability, which are essential for producing high-quality aluminum castings. This means that customers can enjoy both environmental and operational benefits by switching to the green sand option.Furthermore, the company's expertise and commitment to innovation ensure that customers receive the highest level of support and service. Their team of experienced professionals is available to provide technical assistance and guidance to help customers seamlessly transition to using green sand for their aluminum casting needs.The introduction of this green sand option aligns with the company's overarching mission to provide sustainable and innovative solutions to the metal casting industry. By leveraging their expertise and resources, the company is driving positive change and setting new standards for eco-friendly practices in the industry.In response to the news, industry professionals and environmental advocates have praised the company for its efforts to promote sustainability in aluminum casting. The introduction of the green sand option has been widely regarded as a significant step towards reducing the environmental impact of the casting process and advancing the industry towards a more sustainable future.The adoption of green sand for aluminum casting represents a broader trend towards sustainable and eco-friendly practices in the manufacturing and industrial sectors. As companies across industries seek to minimize their environmental footprint, the availability of green sand as a viable alternative to traditional casting materials has the potential to make a meaningful impact on the industry as a whole.Moving forward, the company remains dedicated to furthering its commitment to sustainability and innovation, with plans to continue developing and expanding its range of eco-friendly products and services. This not only demonstrates their proactive approach to addressing environmental challenges but also positions them as a leader in driving positive change within the industry.In conclusion, the introduction of green sand for casting aluminum by the company represents a significant advancement in the industry's efforts towards sustainability. By offering a safe, effective, and environmentally friendly alternative to traditional casting materials, the company is not only meeting the evolving needs of its customers but also contributing to a greener and more sustainable future for the aluminum casting process. As the demand for eco-friendly solutions continues to grow, the company's innovative approach and commitment to sustainability serve as an example for the broader industry to follow.

Discover the Wonders of High-Quality Car Scrap Parts for Your Vehicle

Title: Car Scrap Parts: An Eco-friendly Solution for Automotive WasteIntroduction:In today's world, where environmental concerns are at the forefront, finding sustainable alternatives to various industrial practices has become imperative. The automotive industry, in particular, is notorious for generating tons of waste, contributing to pollution and resource depletion. However, an innovative company, known for its exceptional expertise in recycling and waste management, has emerged with an eco-friendly solution. Let us delve into the world of Car Scrap Parts and explore how they are revolutionizing the automotive waste industry.Company Introduction:Car Scrap Parts, a pioneering company in the field of recycling and waste management, is committed to reducing environmental impact and fostering a circular economy. Founded in [year] by a team of passionate environmental enthusiasts, the company aims to dismantle and recycle automotive scrap parts, ensuring minimal wastage and maximum utilization of resources.By partnering with various automotive manufacturers, dealerships, and scrapyards, Car Scrap Parts has built a vast network that enables them to collect scrap parts from across the country. Their state-of-the-art facility, equipped with cutting-edge technology and machinery, facilitates the efficient dismantling and segregation of various automotive components.News Content:[Paragraph 1]Car Scrap Parts is making significant strides in reshaping the automotive waste industry by offering a sustainable approach to managing end-of-life vehicles. Through their meticulous dismantling process, they extract valuable parts that can be refurbished and reused, thus reducing the need for manufacturing new components. This not only saves resources but also helps in curbing carbon emissions associated with the production of new parts.[Paragraph 2]In addition to the environmental benefits, Car Scrap Parts has also introduced a unique identification system that ensures traceability and origin certification for each recycled part. This system guarantees that customers can confidently purchase recycled components, knowing they are authentic and meet the required standards.[Paragraph 3]Car Scrap Parts understands the importance of quality and safety when it comes to recycled automotive parts. Accordingly, they have a stringent quality control process in place, ensuring that every part passes rigorous testing before reaching the market. Their commitment to excellence has earned them recognition from industry experts and reinforced their position as a trusted provider of recycled components.[Paragraph 4]To support the transition towards a circular economy, Car Scrap Parts actively collaborates with automotive manufacturers to develop innovative recycling techniques. By sharing their knowledge and expertise, they spearhead research and development programs to find sustainable alternatives for various automotive materials. Such initiatives contribute to the industry's shift from linear to circular practices.[Paragraph 5]Being environmentally responsible doesn't stop at recycling for Car Scrap Parts. They have also adopted measures to minimize their own carbon footprint during the recycling process. By optimizing their operations and investing in renewable energy sources, such as solar power, they aim to further reduce their impact on the environment and inspire others in the industry to follow suit.[Paragraph 6]Car Scrap Parts is committed to raising awareness about the significance of responsible waste management. Through educational initiatives, workshops, and collaborations with environmental organizations, they aim to inform the public, automotive enthusiasts, and industry professionals about the benefits of recycling and the critical role it plays in creating a sustainable future.Conclusion:Car Scrap Parts is a trailblazer in the automotive waste management sector, revolutionizing the way we perceive and manage end-of-life vehicles. Through their sustainable practices, commitment to quality, and dedication to raising awareness, they are setting a benchmark for the entire industry. By partnering with Car Scrap Parts, automotive manufacturers, dealerships, and consumers can contribute to the preservation of the environment while opting for high-quality recycled parts.With their innovative solutions and unwavering commitment to sustainability, Car Scrap Parts is paving the way for a greener and more responsible automotive industry.

Top 10 Best Car Engine Heaters 2021 - Reviews and Buying Guide

Car Engine Heater – Keeping your Engine Warm in Cold WeatherAs the temperatures drop and the winter season sets in, one of the biggest concerns for car owners is ensuring that their engine starts smoothly in the cold weather. A reliable and efficient solution to this problem is the innovative Car Engine Heater offered by {}.With over 20 years of experience in the automotive industry, {} is a leading provider of high-quality car accessories and performance parts. The company has earned a reputation for its commitment to excellence and customer satisfaction, and the Car Engine Heater is a testament to their dedication to providing practical and effective solutions for car owners.The Car Engine Heater is designed to keep the engine warm in cold weather conditions, making it easier to start the car and reducing wear and tear on the engine. The heater works by heating the engine coolant and circulating it throughout the engine block, ensuring that the oil and other vital fluids remain at an optimal temperature for smooth and efficient operation. This not only helps to improve fuel efficiency, but also extends the life of the engine and reduces the risk of damage caused by cold starts.One of the key advantages of the Car Engine Heater is its user-friendly design and easy installation process. It can be easily mounted to the engine block and connected to the vehicle's electrical system, making it a convenient and practical solution for car owners. Additionally, the heater is equipped with safety features to prevent overheating and ensure reliable performance in all weather conditions.In addition to its functionality, the Car Engine Heater is also designed with energy efficiency in mind. It is engineered to operate with minimal power consumption, making it an environmentally-friendly and cost-effective solution for car owners. This not only helps to reduce the carbon footprint of the vehicle, but also saves on fuel costs in the long run.The Car Engine Heater is compatible with a wide range of vehicle makes and models, making it a versatile and practical solution for car owners across different regions and climates. Whether you live in a cold, snowy climate or simply want to ensure smooth engine starts during the winter months, the heater offers a reliable solution to meet your needs.With the winter season approaching, now is the perfect time to invest in a Car Engine Heater from {}. Whether you are looking to improve the performance of your vehicle, extend the life of your engine, or simply enjoy the convenience of a warm engine on cold mornings, the Car Engine Heater is the ideal solution for all car owners.In conclusion, the Car Engine Heater offered by {} is a practical, efficient, and reliable solution for keeping your engine warm in cold weather conditions. With its user-friendly design, energy efficiency, and compatibility with a wide range of vehicles, the heater is a must-have accessory for car owners looking to protect their engines and enjoy smooth starts throughout the winter season. The team at {} is committed to providing exceptional products and customer satisfaction, and the Car Engine Heater is a testament to their dedication to excellence in the automotive industry.

Essential Car Door Handle Parts: A Comprehensive Guide

Car Door Handle Parts: The Perfect Fit for Your VehicleCar owners know the feeling of frustration that comes when their car doors refuse to open. One of the most common issues that car owners face is malfunctioning door handles. A broken door handle makes it difficult for drivers and passengers to enter or exit the vehicle, and can potentially compromise their safety. Fortunately, Car Door Handle Parts (CDHP) has emerged as a reliable and affordable solution to this age-old problem.CDHP is a leading manufacturer of car door handle parts. For over a decade, the company has been providing high-quality replacement parts to car owners and repair shops across the globe. With an extensive product line that spans several makes and models, CDHP has become the go-to choice for those seeking an affordable and reliable solution to their car door handle woes.The company takes great pride in its commitment to quality and customer satisfaction. CDHP utilizes state-of-the-art processes and technology to ensure that its products meet the strictest quality standards. From precision engineering to rigorous testing, every aspect of the manufacturing process is carefully monitored to ensure that the end product is of the highest quality.A key factor that sets CDHP apart from other manufacturers is the company’s commitment to affordability. CDHP believes that every car owner should be able to access high-quality replacement parts without breaking the bank. With this in mind, the company offers its products at highly competitive prices, making it accessible to a wider audience.CDHP’s product line includes door handles for several popular car brands, including Honda, Toyota, Nissan, and Ford. The company offers a range of products to suit different needs and preferences. Whether you’re looking for a basic replacement part or a more customized option, CDHP has got you covered.One of the most popular products offered by CDHP is the Exterior Door Handle. This product is designed to replace the original handle on your car door, providing a perfect fit and seamless integration with your vehicle. The Exterior Door Handle comes in a range of colors and finishes, allowing customers to choose a look that suits their preferences.Another popular product offered by CDHP is the Interior Door Handle. This product is designed to replace the handle on the inside of your car door, providing a smooth and comfortable grip when opening and closing the door. The Interior Door Handle comes in a range of materials and finishes, making it easy to find a product that matches your car’s interior.CDHP’s commitment to quality and affordability has earned the company a loyal customer base. Customers appreciate the company’s attention to detail and willingness to go the extra mile to ensure their satisfaction. With a five-star rating on several popular e-commerce platforms, it’s clear that CDHP is a top choice for those seeking reliable and affordable car door handle parts.In conclusion, CDHP is a leading manufacturer of car door handle parts that offers high-quality products at affordable prices. With an extensive product line and a commitment to customer satisfaction, CDHP has become a top choice for car owners and repair shops across the globe. Whether you’re in need of a basic replacement part or a more customized option, CDHP has got you covered. With CDHP’s products, you can restore your car’s functionality and enhance its aesthetic appeal, all while saving money.

Discover the Strength and Versatility of Iron Castings in Today's Market

[Company Name] Revolutionizes the Iron Castings Industry with Innovative Techniques[date][City, State] - In a groundbreaking development, [Company Name] has introduced cutting-edge techniques that are set to revolutionize the iron castings industry. With their commitment to innovation, this industry leader is poised to challenge traditional casting methods, offering a game-changing approach that promises enhanced quality, efficiency, and sustainability.Iron casting has long been a vital process in numerous sectors, from automotive and aerospace to construction and industrial manufacturing. However, traditional methods have often proven time-consuming, inefficient, and limited in terms of design flexibility. This is where [Company Name] steps in, leveraging their expertise, state-of-the-art technology, and a forward-thinking philosophy to transform the iron castings landscape.[Company Name] has invested heavily in research and development, resulting in the creation of proprietary techniques that overcome many of the limitations of traditional methods. By combining advanced materials science with cutting-edge manufacturing processes, they have achieved remarkable results that are set to redefine the industry standards.One of the key advancements by [Company Name] is their breakthrough sand printing technology. This process utilizes computer-aided design (CAD) software and 3D printing to create sand molds with intricate shapes and complex internal geometries. By eliminating the need for expensive tooling and reducing lead times, this technique offers unprecedented design freedom and cost-effectiveness. Additionally, it significantly reduces material waste, making it an eco-friendly alternative to conventional casting processes.The sand printing technology developed by [Company Name] has already yielded remarkable successes in various applications. The automotive industry, for instance, has quickly recognized the value of this innovative technique, enabling them to create lightweight and intricate cast components for high-performance vehicles. The aerospace sector has also embraced this technology, utilizing it to manufacture complex turbine blades with unmatched precision and efficiency.Moreover, [Company Name] has introduced another groundbreaking method known as "cast iron foam." This technique involves the addition of a foaming agent to molten iron, resulting in a lightweight yet structurally superior material. Cast iron foam exhibits exceptional strength-to-weight ratios, making it a perfect choice for applications requiring both strength and reduced weight. This innovation opens up new possibilities in automotive and aerospace industries, where fuel efficiency is paramount.Beyond the technical advancements, [Company Name] has taken a holistic approach to sustainable and responsible manufacturing. The sand printing technology, in particular, significantly reduces energy consumption and greenhouse gas emissions compared to traditional casting methods. By minimizing waste and optimizing resource usage, [Company Name] is actively contributing to a greener future for the industry.While acknowledging the importance of their breakthrough techniques, [Company Name] remains committed to collaboration and strategic partnerships. They aim to work closely with their customers, understanding their unique requirements, and providing tailored solutions. Whether it’s in the automotive sector, aerospace industry, or any other field, [Company Name] is ready to forge mutually beneficial relationships that will drive innovation and propel the iron castings industry forward.These developments by [Company Name] mark a significant milestone in the iron castings industry. By challenging conventional methods and pushing the boundaries of what is possible, [Company Name] is spearheading a new era of quality, efficiency, and sustainability. With their groundbreaking sand printing technology and cast iron foam, they are poised to transform multiple sectors and inspire others to embrace innovation for a brighter future.

Exploring the Advantages of Aluminum Alloy Die Casting for Industrial Manufacturing

Aluminum Alloy Die Casting Revolutionizes Manufacturing: A Step Towards Efficiency and DurabilityIn today's rapidly evolving manufacturing industry, companies are constantly seeking innovative solutions to enhance efficiency and deliver products of exceptional quality. One of the most recent advancements in this field is the introduction of Aluminum Alloy Die Casting, a technique that has significantly transformed the way products are manufactured. This groundbreaking process, employed by numerous industry leaders such as [], offers an unmatched combination of strength, lightweight construction, and precision.Aluminum Alloy Die Casting is a metalworking process that starts with molten aluminum being injected into a mold under high pressure. This sophisticated technique ensures the creation of complex and detailed products with utmost accuracy. Its exceptional dimensional stability allows for the production of intricate designs that were previously unachievable. This translates into limitless possibilities for designers and engineers, enabling them to push boundaries and bring their creative concepts to life.The inherent strength of aluminum, combined with the die casting process, makes it an ideal material for various industries such as automotive, aerospace, electronics, and consumer goods. By utilizing Aluminum Alloy Die Casting, companies can produce components that are not only exceptionally light but also possess superior mechanical properties. This results in products that exhibit enhanced structural integrity, guaranteeing long-lasting performance and reduced maintenance costs.Furthermore, the lightweight nature of aluminum alloys significantly contributes to energy efficiency. As modern industries are increasingly focused on sustainability, Aluminum Alloy Die Casting plays a pivotal role in creating eco-friendly solutions. Lighter products mean reduced fuel consumption in transportation and lower energy requirements in various applications, thereby promoting a greener and more sustainable future.In addition to its strength and lightweight attributes, Aluminum Alloy Die Casting offers exceptional thermal conductivity. This unique characteristic allows for efficient heat dissipation, making it particularly suitable for applications where temperature management is crucial. By ensuring optimal heat transfer, products produced through this technique are more resistant to thermal stress, improving their reliability and longevity.The adoption of Aluminum Alloy Die Casting has also introduced notable cost-effectiveness to the manufacturing process. With its ability to produce high-quality components at a rapid rate, manufacturers can streamline their production cycles and reduce both time and labor costs. The precision, repeatability, and intricacy of this technique further minimize the need for post-processing, resulting in a significant reduction in overall manufacturing expenses.Moreover, the versatility of Aluminum Alloy Die Casting allows for the integration of multiple parts into a single component. By consolidating several separate pieces, companies can eliminate potential weak points and enhance the overall structural integrity of their products. This not only increases efficiency but also reduces the final assembly time, resulting in shorter lead times for customers.As industry leaders continue to embrace the advantages of Aluminum Alloy Die Casting, technological advancements are continuously pushing the boundaries of what is achievable. Through extensive research and development, manufacturers have uncovered methods to improve the mechanical properties of aluminum alloys, further expanding the applications of this revolutionary process. As a result, industries ranging from automotive to telecommunications are witnessing an unprecedented level of innovation, offering customers cutting-edge products that are both durable and efficient.In conclusion, Aluminum Alloy Die Casting represents a significant leap forward in the manufacturing industry. With its outstanding strength, lightweight construction, precision, and cost-effectiveness, this technique has revolutionized the way products are made. As more companies embrace this innovative process, we can expect a future where efficiency, durability, and sustainability are the norm.

Quality Aluminium Bronze Casting for Various Applications

Aluminium Bronze Casting is a specialized method of creating high-quality metal components using a combination of aluminium and bronze. This process is widely used in various industries such as automotive, aerospace, marine, and more. The unique properties of aluminium bronze make it an ideal choice for casting applications where strength, corrosion resistance, and durability are essential.With a history of excellence in the field of metal casting, {company name} has established itself as a leading provider of Aluminium Bronze Casting services. The company has a state-of-the-art facility equipped with the latest technology and machinery to ensure precision and quality in every casting project. Their team of highly skilled engineers and technicians are dedicated to delivering custom solutions to meet the unique needs of their clients.“We take great pride in our ability to provide top-notch Aluminium Bronze Casting services to a wide range of industries,” says {company spokesperson}. “Our commitment to quality, reliability, and customer satisfaction sets us apart as a trusted partner for all casting needs.”The unique combination of aluminium and bronze in the casting process results in a material that offers exceptional strength, corrosion resistance, and thermal conductivity. This makes aluminium bronze an ideal choice for applications where reliability and performance are crucial. Whether it's for manufacturing components for heavy machinery, marine equipment, or aerospace parts, Aluminium Bronze Casting offers unmatched durability and longevity.In addition to its mechanical properties, aluminium bronze also offers an attractive aesthetic appeal, making it a popular choice for architectural and decorative applications. Its rich gold color and attractive finish make it a preferred material for artistic and ornamental casting projects.Furthermore, Aluminium Bronze Casting is known for its excellent resistance to corrosion, making it an ideal choice for marine and offshore applications. The material's ability to withstand harsh marine environments, including corrosion from saltwater and exposure to the elements, makes it a valuable choice for components used in marine equipment and offshore structures.{company name}’s expertise in Aluminium Bronze Casting extends to the precision casting of intricate and complex shapes, ensuring that the final components meet the highest standards of quality and accuracy. Their advanced casting techniques and stringent quality control measures guarantee that every component meets the exact specifications of the client.The company's dedication to utilizing the latest technology and industry best practices ensures that their Aluminium Bronze Casting services remain at the forefront of the industry. They continue to invest in research and development to improve their casting processes and offer innovative solutions to their clients.With a proven track record of delivering exceptional results and superior customer service, {company name} has built a reputation as a trusted partner for Aluminium Bronze Casting needs. Their commitment to excellence, combined with their technical expertise and state-of-the-art facility, positions them as a leader in the field of metal casting.As the demand for high-quality, reliable, and durable metal components continues to grow across various industries, Aluminium Bronze Casting remains a popular choice for meeting these needs. With its unique combination of properties and benefits, coupled with the expertise and capabilities of {company name}, clients can be confident in the quality and reliability of their casting projects.

High-Quality Aluminum Casting Die for Industrial Applications

Aluminum Casting Die: The Backbone of Manufacturing at {}In the world of manufacturing, precision and quality are the driving forces behind successful production processes. One essential component that plays a crucial role in achieving these benchmarks is the aluminum casting die. This vital tool is utilized in the production of a wide range of products, from automotive parts to consumer goods. At {}, the use of aluminum casting dies has been instrumental in the company's success and reputation as a leading manufacturer in the industry.With a focus on innovation and cutting-edge technology, {} has consistently pushed the boundaries of what is possible in the manufacturing sector. The company has invested heavily in state-of-the-art machinery and equipment, including advanced aluminum casting dies, to ensure that their products meet the highest standards of quality and precision.The aluminum casting die is a specialized tool that is used to create complex and intricate parts through the process of aluminum die casting. This method involves injecting molten aluminum into the die under high pressure, allowing it to solidify and take the shape of the mold. The result is a finished product that exhibits exceptional dimensional accuracy and surface finish, making it ideal for a wide range of applications.One of the key advantages of using aluminum casting dies is the ability to produce high-quality parts at a rapid pace. This increased efficiency allows {} to fulfill large orders in a timely manner, meeting the demands of their clients and maintaining a competitive edge in the market. Furthermore, the durability and longevity of aluminum casting dies ensure that they can withstand the rigors of high-volume production, making them a cost-effective solution for manufacturing operations.The expertise and skill of {}'s team of engineers and technicians are evident in the meticulous design and construction of their aluminum casting dies. Each die is customized to meet the specific requirements of the product being manufactured, ensuring that every detail is precision-engineered to exact specifications. This attention to detail is a testament to {}'s commitment to delivering superior products that exceed the expectations of their customers.In addition to their commitment to quality, {} also places a strong emphasis on sustainability and environmental responsibility. Aluminum casting is a highly efficient and recyclable process, making it an eco-friendly choice for manufacturing. By utilizing aluminum casting dies, {} is able to minimize waste and reduce their environmental impact, aligning with their dedication to corporate social responsibility and sustainable practices.Looking ahead, {} continues to explore new opportunities for advancement in the realm of aluminum casting die technology. By staying at the forefront of industry trends and developments, the company is poised to further enhance their capabilities and expand their offerings to meet the evolving needs of their customers.In conclusion, aluminum casting dies play a pivotal role in the manufacturing operations at {}. The company's investment in cutting-edge technology and unwavering dedication to quality has positioned them as a leader in the industry. With a focus on innovation, sustainability, and customer satisfaction, {} is well-positioned to continue delivering excellence in the realm of aluminum die casting for years to come.