High-Quality Auto Parts for Diesel Vehicles: Find What You Need

By:Admin

Diesel Auto Parts, a leading provider of automotive parts and accessories, has recently made waves in the automotive industry with their launch of innovative new products designed to meet the evolving needs of car owners and mechanics alike. With a focus on providing high-quality, reliable parts at affordable prices, Diesel Auto Parts is paving the way for a more efficient and sustainable automotive industry.

Founded in 2005, Diesel Auto Parts has become a trusted name in the automotive aftermarket, offering a wide range of products including fuel injection systems, turbochargers, diesel engine parts, and more. With a commitment to staying ahead of industry trends and technological advancements, the company has continuously invested in research and development to bring innovative solutions to the market.

The latest products released by Diesel Auto Parts have been met with much anticipation and excitement within the industry. One such product is the newly designed fuel injection system, which promises to deliver improved fuel efficiency and reduced emissions. This innovation comes at a time when environmental sustainability is a top priority for the automotive sector, making Diesel Auto Parts’ fuel injection system a game-changer for car owners and manufacturers alike.

In addition to their fuel injection system, Diesel Auto Parts has also unveiled a new line of turbochargers that are engineered for maximum performance and durability. These turbochargers are designed to enhance engine power and efficiency, offering a cost-effective solution for improving vehicle performance without compromising on reliability.

The company’s commitment to product excellence is further exemplified by their range of high-quality diesel engine parts, which are manufactured to the highest standards to ensure optimal performance and longevity. Whether it’s a replacement piston, camshaft, or cylinder head, Diesel Auto Parts has a comprehensive selection of engine parts to meet the needs of automotive professionals and enthusiasts.

Diesel Auto Parts’ dedication to customer satisfaction extends beyond the products they offer. The company places great emphasis on providing exceptional customer service, ensuring that their clients receive knowledgeable support and assistance when selecting the right parts for their vehicles. This commitment to excellence has earned Diesel Auto Parts a loyal customer base and a strong reputation for reliability and integrity.

As the automotive industry continues to evolve, Diesel Auto Parts remains at the forefront of innovation, constantly striving to develop cutting-edge products that meet the changing demands of the market. With a keen eye on future trends and advancements, the company is well-positioned to drive the industry forward and set new standards for performance, efficiency, and environmental sustainability.

Looking ahead, Diesel Auto Parts has ambitious plans to expand their product line and reach new markets, both domestically and internationally. With a growing network of distributors and strategic partnerships, the company is poised for significant growth and success in the coming years.

In summary, Diesel Auto Parts’ recent launch of innovative products is a testament to their unwavering commitment to excellence and innovation. With a focus on delivering superior quality, reliability, and value, the company is poised to make a lasting impact on the automotive industry, setting the stage for a more sustainable and efficient future. Whether it’s through their fuel injection systems, turbochargers, or engine parts, Diesel Auto Parts is driving the industry forward with innovation and passion.

Company News & Blog

Top Quality Car Interior Parts for Sale

Car Interior Parts transforms the driving experience with their innovative and high-quality interior components. With a strong focus on both style and functionality, Car Interior Parts has quickly become a leading provider in the automotive aftermarket industry.Utilizing state-of-the-art technology and top-of-the-line materials, Car Interior Parts offers a wide range of interior components including dashboards, door panels, center consoles, seats, and more. Each product is meticulously designed and engineered to meet the highest standards of quality and performance.One of the company's most popular products is their custom-designed, {insert brand name} dashboard. This sleek and modern dashboard not only enhances the overall look of the car's interior but also provides added functionality with its advanced features. It is constructed with durable materials that are built to last, ensuring long-term satisfaction for customers.In addition to their dashboards, Car Interior Parts also offers a variety of door panels that are designed to complement the overall aesthetics of the vehicle's interior. These door panels are available in a range of styles and finishes, allowing customers to personalize their driving space to their specific tastes.Furthermore, Car Interior Parts takes great pride in their center console offerings. These consoles are expertly crafted to provide convenient storage solutions while adding a touch of luxury to the car's interior. With an array of customization options, customers can choose the perfect center console to suit their needs and preferences.When it comes to seating, Car Interior Parts offers a range of options to cater to different preferences. From sporty racing seats to luxurious leather upholstery, the company provides a diverse selection of seats that are designed for both comfort and performance.Car Interior Parts is dedicated to delivering products that not only meet, but exceed, the expectations of their customers. The company is committed to staying abreast of the latest trends and advancements in automotive interior design, ensuring that their products are always at the forefront of innovation.In addition to their commitment to innovation, Car Interior Parts is also focused on providing exceptional customer service. The company's knowledgeable and friendly staff are always available to assist customers in finding the perfect interior components for their vehicles. Whether it's providing expert advice or answering product-related questions, Car Interior Parts prioritizes customer satisfaction above all else.Furthermore, Car Interior Parts strives to ensure that their products are easily accessible to customers. With an intuitive online platform, customers can easily browse through the company's extensive catalog and place orders with just a few clicks. Additionally, the company works with a network of authorized dealers to ensure that their products are readily available to consumers around the world.As a company that is deeply passionate about automotive interior design, Car Interior Parts is constantly pushing the boundaries of innovation to deliver products that not only meet, but exceed, the expectations of their customers. With a steadfast commitment to quality, functionality, and style, Car Interior Parts is poised to continue making waves in the automotive aftermarket industry.

High-Quality Large Steel Castings: A Guide to Manufacturing and Applications

Large Steel Casting Company, a world-leading manufacturer of large steel castings for various industries, has announced its commitment to providing high-quality products and services to its global customers.With a history dating back to 1985, Large Steel Casting Company has become a trusted supplier of large steel castings for industries such as mining, construction, energy, and transportation. The company's dedication to innovation and excellence has earned them a reputation for delivering top-notch products that meet the highest industry standards.Large Steel Casting Company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, enabling the company to produce large steel castings of various sizes and complexities. Their team of highly skilled engineers and technicians are committed to delivering custom solutions that meet the unique needs and specifications of their customers.This commitment to excellence has allowed Large Steel Casting Company to build strong and long-lasting partnerships with some of the world's leading companies in the mining, construction, and energy sectors. Their products are utilized in a wide range of applications, including mining equipment, construction machinery, power generation, and transportation infrastructure.In addition to their dedication to producing high-quality products, Large Steel Casting Company also places a strong emphasis on sustainability and environmental responsibility. The company has implemented strict environmental standards and practices throughout its manufacturing processes to minimize its impact on the environment. They also work closely with their suppliers and customers to ensure that their products are designed and manufactured with sustainability in mind.To further demonstrate their commitment to quality and customer satisfaction, Large Steel Casting Company has implemented a rigorous quality control system that ensures all their products meet the highest standards of performance and reliability. Their dedication to quality has earned them ISO 9001 certification, as well as numerous industry awards and accolades.In addition to their manufacturing capabilities, Large Steel Casting Company also offers a range of value-added services to their customers, including engineering support, technical consultation, and after-sales service. Their team of experts is available to work closely with customers to develop custom solutions that meet their specific needs and requirements.Furthermore, Large Steel Casting Company places a strong emphasis on research and development, constantly investing in new technologies and methodologies to improve their manufacturing processes and product performance. This commitment to innovation has enabled the company to stay at the forefront of the industry and offer cutting-edge solutions to its customers.As Large Steel Casting Company continues to grow and expand its global presence, they remain committed to their core values of excellence, innovation, and customer satisfaction. The company's dedication to quality and sustainability, combined with their unmatched expertise and capabilities, positions them as a leading provider of large steel castings for industries worldwide.In conclusion, Large Steel Casting Company's commitment to excellence, innovation, and sustainability sets them apart as a trusted partner for companies looking for high-quality large steel castings. With a proven track record of delivering top-notch products and services, the company is well-positioned to continue leading the industry for years to come.

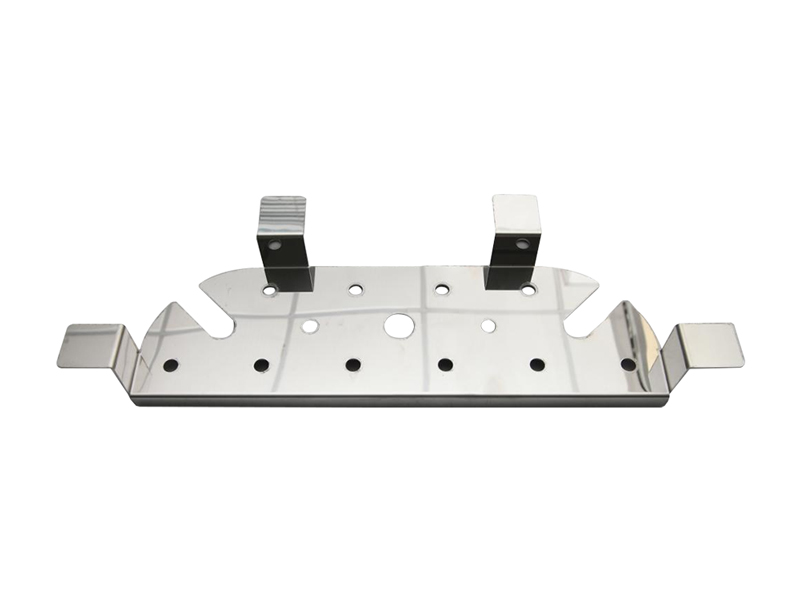

Advanced Techniques for Automotive Sheet Metal Stamping

Automotive Sheet Metal Stamping Company Continues to Excel in the IndustryAutomotive Sheet Metal Stamping (ASMS) is a leading player in the global automotive industry, offering a range of solutions to some of the biggest names in the sector. The company’s unwavering commitment to quality and innovation has helped it carve out a niche in the industry, streamlining operations and increasing production efficiency.ASMS has a rich history, with its roots tracing back to the early 1900s. Over the years, the company has consistently expanded its footprint, investing heavily in research and development, and upgrading its facilities to meet the evolving needs of its customers.Today, ASMS is a reliable partner for companies looking to outsource their sheet metal stamping needs. The company provides a range of services, including blanking, piercing, forming, drawing, folding, and welding, among others. With state-of-the-art machinery and skilled technicians, ASMS is well-equipped to handle any project, no matter how complex.At ASMS, quality is a top priority. The company has implemented stringent quality control measures to ensure that its products meet the highest standards. ASMS has been certified to ISO 9001:2015, underscoring its commitment to quality management and customer satisfaction.The company’s versatile product range includes parts for a variety of vehicles, from passenger cars to heavy-duty trucks. Customers can rely on ASMS to provide parts that are precise, reliable, and durable, ensuring a longer lifespan for their vehicles.ASMS has also reaped benefits from the increasing demand for electric vehicles (EVs) and the changing landscape of the automotive industry. The company has invested heavily in R&D efforts to develop new materials for EVs, such as lightweight aluminum alloys and high-strength steels. These materials are essential to enhancing the performance and safety of EVs, reducing their weight, and improving their range.The company is also a leader in sustainability and is committed to minimizing its impact on the environment. ASMS has implemented green practices across its operations, such as the use of renewable energy sources and reducing waste through the adoption of recycling initiatives.In 2020, ASMS launched a new product line, the “Green Series,” which consists of parts made from recycled materials. The series was designed to cater to the growing demand for eco-friendly products and demonstrates the company’s dedication to sustainability.ASMS is a testament to how a company can thrive in the highly competitive automotive industry by embracing innovation, quality, and sustainability. The company takes pride in its ability to meet the needs of its customers, and it has earned a reputation as a reliable and trustworthy partner.The future looks bright for ASMS as it continues on its journey to drive innovation and lead the way in the automotive industry. With an unwavering commitment to quality, sustainability, and customer satisfaction, ASMS will undoubtedly continue to excel in the years to come.

High-quality Aluminum Alloy Investment Casting: A Complete Guide

Aluminum Alloy Investment Casting: Paving the Way for Advanced Engineering SolutionsInvestment casting is a manufacturing process that has been used for centuries to create metal components with intricate shapes and intricate details. In recent years, the use of aluminum alloys in investment casting has gained popularity due to their lightweight, high strength, and corrosion-resistant properties. One company that has been at the forefront of this trend is {Company Name}.{Company Name} is a leading manufacturer of aluminum alloy investment castings, serving a wide range of industries including aerospace, automotive, defense, and medical. The company has built a reputation for producing high-quality, complex parts with tight tolerances and superior surface finishes. Their expertise in aluminum alloy investment casting has enabled them to offer innovative solutions to their customers’ most challenging engineering problems.One of the key advantages of aluminum alloy investment casting is its ability to produce parts with thin walls, complex geometries, and fine details. This makes it an ideal choice for applications where weight reduction and high performance are crucial. For example, in the aerospace industry, aluminum alloy investment castings are used to manufacture aircraft components such as engine mounts, wing ribs, and structural fittings. The lightweight nature of aluminum alloys helps to reduce overall aircraft weight, leading to improved fuel efficiency and lower operating costs.In the automotive sector, aluminum alloy investment castings are utilized for various applications such as transmission housings, engine parts, and suspension components. The use of aluminum alloys in these components not only helps to reduce vehicle weight but also enhances overall performance and fuel efficiency. Furthermore, the corrosion-resistant properties of aluminum alloys make them an attractive choice for components that are exposed to harsh environmental conditions.The defense industry also benefits from the use of aluminum alloy investment castings in the manufacturing of components for military vehicles, weapons systems, and communications equipment. The lightweight and high-strength characteristics of aluminum alloys make them an ideal material for meeting the stringent requirements of defense applications.Moreover, in the medical industry, aluminum alloy investment castings are used to produce critical components for medical devices and equipment. The biocompatibility of aluminum alloys, along with their superior mechanical properties, makes them suitable for a wide range of medical applications.In addition to its widespread use in various industries, aluminum alloy investment casting offers several other advantages such as cost-effectiveness, design flexibility, and the ability to produce near-net-shaped parts, reducing the need for secondary machining operations. With the advancement of casting technology and computer-aided design (CAD), complex shapes and intricate details can be achieved with high precision, enabling manufacturers to produce parts that were once deemed impossible through traditional manufacturing processes.As a leader in aluminum alloy investment casting, {Company Name} has continued to invest in state-of-the-art equipment, advanced materials, and process optimization techniques. This has allowed them to expand their capabilities and produce components that meet the most demanding requirements of their customers. The company’s experienced team of engineers, metallurgists, and manufacturing experts work closely with customers from the initial design phase through to the final production, ensuring that the end product meets the highest quality standards.As the demand for lightweight, high-performance components continues to grow across industries, the use of aluminum alloy investment casting is expected to play a significant role in the future of engineering solutions. With its unparalleled capability to produce complex, high-quality parts with a competitive edge, {Company Name} is well-positioned to meet the evolving needs of its customers and contribute to the advancement of engineering and manufacturing technologies.In conclusion, aluminum alloy investment casting has opened up new possibilities for designing and producing advanced components that deliver superior performance, lightweight design, and cost-effectiveness. With {Company Name} leading the way in this field, the potential for innovation and advancement in engineering solutions is indeed promising.

Discover the Benefits of Vacuum Casting Aluminum for Your Next Project

Vacuum Casting Aluminum, a cutting-edge technology that revolutionizes the production of high-quality aluminum parts, has been making waves in the manufacturing industry. This innovative process has been gaining traction for its ability to create complex and intricate aluminum components with unmatched precision and efficiency.With Vacuum Casting Aluminum, manufacturers are able to produce aluminum parts that are free from porosity and other defects commonly found in traditional casting methods. This process involves pouring molten aluminum into a mold under vacuum pressure, which significantly reduces the formation of gas porosity and ensures a more even distribution of the metal throughout the mold. The result is a finished product that is not only structurally sound, but also has a smooth surface finish, making it ideal for a wide range of applications across various industries.One company that has been at the forefront of this technology is {company name}. With a strong focus on innovation and quality, {company name} has become a leading provider of Vacuum Casting Aluminum services to industries such as aerospace, automotive, and electronics. By leveraging their expertise in aluminum casting and state-of-the-art facilities, {company name} has been able to deliver exceptional aluminum parts that meet the strictest industry standards.Established in {year}, {company name} has continuously invested in cutting-edge technology and modern manufacturing processes to stay ahead of the competition. Their commitment to excellence has not only propelled them to become a trusted partner for leading companies, but also a trailblazer in the advancement of aluminum casting techniques.The Vacuum Casting Aluminum process offered by {company name} begins with the creation of a master pattern from a 3D CAD model. This master pattern is then used to produce a silicone mold, which is placed in a vacuum chamber for the casting process. By carefully controlling the temperature and pressure within the chamber, {company name} is able to achieve precise and consistent results, ensuring that each aluminum part meets the exact specifications of their clients.One of the key advantages of Vacuum Casting Aluminum is its ability to produce complex and intricate parts with minimal tooling costs. This makes it an ideal solution for companies looking to create low to mid-volume production runs without the need for expensive tooling and long lead times. It also allows for rapid prototyping and iterative design changes, enabling faster time-to-market for new products.{company name} prides itself on its ability to work closely with their clients from the initial design phase through to the final production. Their team of experienced engineers and technicians are dedicated to providing comprehensive support and guidance, ensuring that each project is completed to the highest standard. This customer-centric approach has earned them a reputation for reliability and satisfaction among their clients.In addition to Vacuum Casting Aluminum, {company name} offers a wide range of secondary processes to further enhance the performance and aesthetics of aluminum parts. These include machining, surface finishing, and heat treatment, all of which are carried out with the same level of precision and attention to detail.As the demand for high-quality aluminum components continues to grow across various industries, the adoption of Vacuum Casting Aluminum is expected to rise. With its ability to produce superior parts with exceptional accuracy and efficiency, this innovative process is poised to become the go-to solution for manufacturers seeking to stay competitive in today's market.In conclusion, {company name} and their state-of-the-art Vacuum Casting Aluminum process are setting a new standard for the production of aluminum parts. Their dedication to innovation, quality, and customer satisfaction is propelling them to the forefront of the industry, making them a reliable and trusted partner for companies seeking premium aluminum components. With a commitment to excellence and a focus on cutting-edge technology, {company name} is well-positioned to lead the way in the advancement of aluminum casting techniques and meet the evolving needs of the manufacturing industry.

Discover the Key Components of Car Wheels: A Comprehensive Guide

Car Wheel Components, a leading manufacturer of high-quality automotive components, has recently emerged as a popular choice for many vehicle owners worldwide. The company specializes in designing and manufacturing a wide range of car parts, including wheels, rims, hubcaps, and other related components. With its commitment to excellence, Car Wheel Components has established itself as a reliable supplier of premium-quality products that are built to last.At the core of Car Wheel Components’ success is its unwavering focus on customer satisfaction. The company understands that its products are essential to the safety and performance of a vehicle, and as such, places great emphasis on ensuring that every item that leaves its factories meets the highest quality standards. As a result, the company has gained a reputation for delivering dependable, durable, and stylish car parts that meet the specific needs of its customers.One of the key elements of Car Wheel Components’ success is its desire to innovate. The company has always been at the forefront of developing new technologies and manufacturing techniques, which has led to the introduction of several revolutionary products. For example, the company’s proprietary alloy wheel technology has become a benchmark for quality and performance in the automotive industry. These wheels are lighter and stronger than traditional steel wheels, which improves vehicle handling, fuel efficiency, and overall performance.In addition to its focus on innovation, Car Wheel Components has always been committed to sustainability. The company recognizes the impact that its products can have on the environment and takes measures to minimize this impact. For example, the company has implemented a recycling program that ensures the responsible disposal of used materials. It also utilizes energy-efficient technologies to reduce its carbon footprint and improve its environmental performance.Car Wheel Components’ success can also be attributed to its highly skilled and dedicated team of professionals. The company employs some of the best engineers, designers, and technicians in the industry, all of whom are committed to delivering the highest quality products and services. Car Wheel Components’ team works tirelessly to develop new designs and manufacturing techniques to keep up with the ever-changing demands of the automotive market.Looking ahead, Car Wheel Components is well-positioned to capitalize on the trends shaping the automotive industry. With the demand for electric and hybrid vehicles set to rise in the coming years, the company is already developing new technologies and products that cater to this market. It is also investing in research and development to explore the possibilities of new materials, manufacturing techniques, and other innovations that will shape the future of automotive components.In conclusion, Car Wheel Components is a company that has established itself as a leader in the automotive industry. With its commitment to innovation, quality, and sustainability, the company has gained the trust and loyalty of its customers around the world. As the company looks to the future, it is poised to continue its growth and success by developing new products, technologies, and partnerships that will enable it to remain at the forefront of the industry.

Durable High Chrome Steel Castings for Industrial Applications

The company is a leading manufacturer of high-quality steel castings, specializing in the production of high chrome steel castings. These castings are used in a wide range of industries, including mining, construction, and machinery manufacturing.High chrome steel castings are known for their exceptional hardness, resistance to abrasion, and high performance in demanding industrial applications. The company has been at the forefront of developing and manufacturing these superior castings for decades, and has built a strong reputation for delivering reliable and durable products to its customers.The company's production facilities are equipped with state-of-the-art technology and equipment, allowing for precise and efficient manufacturing of high chrome steel castings. The company's experienced team of engineers and technicians are dedicated to ensuring that each casting meets the highest quality standards, and that customers receive products that exceed their expectations.In addition to its focus on quality, the company is also committed to sustainability and environmentally-friendly practices. The company's manufacturing processes are designed to minimize waste and reduce environmental impact, and it works with suppliers and partners who share its commitment to sustainability.The company's high chrome steel castings are used in a wide range of applications, including in the mining industry where they are used in equipment such as crushers, grinders, and screens. These castings are essential for the efficient operation of mining operations, and the company's products are trusted by mining companies around the world to deliver outstanding performance and reliability.In the construction industry, the company's high chrome steel castings are used in a variety of equipment and machinery, including in the production of cement, concrete, and asphalt. These castings are durable and resistant to wear and tear, making them an ideal choice for demanding construction applications.The company also serves the machinery manufacturing industry, providing high chrome steel castings for use in a wide range of equipment and machinery, including in the production of heavy-duty industrial equipment and machinery. These castings are designed to withstand the rigors of heavy use and harsh operating conditions, and are trusted by manufacturers to deliver the performance and reliability they need.As a leading manufacturer of high chrome steel castings, the company is committed to providing its customers with exceptional products and exceptional service. The company works closely with its customers to understand their specific needs and requirements, and to deliver solutions that meet and exceed their expectations.The company's commitment to quality, innovation, and sustainability has made it a trusted partner for companies around the world, and its high chrome steel castings are used in a wide range of industries and applications. With a focus on continuous improvement and customer satisfaction, the company is well positioned to continue leading the industry in the manufacturing of high chrome steel castings for years to come.

Essential Car Parts: A Complete Guide to Clutch Car Components

[Company Name] Expands Product Line with New Clutch Car Part[City, Date] - [Company Name], a leading provider of automotive parts, announced the addition of a new clutch car part to its product line. The new addition is designed to enhance the performance and reliability of vehicles, providing customers with a high-quality solution for their clutch system needs.With a mission to deliver innovative and dependable automotive parts, [Company Name] has become a trusted brand in the industry. Known for its commitment to providing superior products, the company continuously seeks to expand its product offerings to meet the evolving needs of its customers.The new clutch car part is the result of extensive research and development efforts by [Company Name]'s team of engineers and technicians. With a focus on performance, durability, and affordability, the company aims to deliver a cutting-edge solution that exceeds customer expectations."The introduction of the new clutch car part aligns with our commitment to offering a comprehensive range of high-quality automotive parts," said [Company Name]'s spokesperson. "We are constantly striving to provide our customers with products that enhance the performance and reliability of their vehicles. This new addition to our product line is a testament to our dedication to delivering exceptional quality and value."[Company Name] understands that a malfunctioning clutch system can lead to various issues such as gear slipping, stalling, or difficulty in engaging gears. Recognizing the importance of a reliable clutch system, the company aims to provide customers with a solution that not only improves performance but also ensures safety on the road.The new clutch car part features state-of-the-art technology, engineered to minimize noise, reduce vibration, and enhance overall driving experience. Made from premium materials, the part is designed to withstand high levels of stress and deliver consistent performance even in extreme conditions. With easy installation and compatibility with a wide range of vehicle models, [Company Name]'s clutch car part provides convenience and flexibility for customers.In addition to its exceptional product quality, [Company Name] is known for its outstanding customer service. The company maintains a team of knowledgeable professionals who are readily available to provide support and guidance to customers. Whether it's assisting with product selection, offering technical advice, or addressing any concerns, [Company Name] ensures that customers receive the assistance they require.With [Company Name]'s vast network of distribution centers, customers can conveniently access the new clutch car part in various locations. The company's commitment to efficient logistics ensures quick and reliable delivery to customers, minimizes downtime, and enables customers to get their vehicles back on the road as soon as possible.As [Company Name] expands its product line, it continues to invest in research and development to introduce advanced and environmentally friendly automotive parts. The company's dedication to sustainability is reflected in its manufacturing processes and commitment to reducing its carbon footprint. By prioritizing eco-friendly practices, [Company Name] aims to contribute positively to the environment and create a greener future.With the introduction of the new clutch car part, [Company Name] solidifies its position as a leading provider of automotive parts. The company's commitment to quality, reliability, and customer satisfaction makes it a preferred choice among vehicle owners and auto service providers.About [Company Name]:[Company Name] is a renowned provider of high-quality automotive parts. With a global presence, the company aims to deliver innovative products that enhance vehicle performance and reliability. Backed by a team of experts and a commitment to customer satisfaction, [Company Name] has become a trusted brand in the industry.For media inquiries:Contact Person: [Spokesperson Name]Title: [Spokesperson Title]Phone Number: [Phone Number]Email: [Email Address]Website: [Company Website]

High-Quality Aluminum Casting Die for Industrial Applications

Aluminum Casting Die: The Backbone of Manufacturing at {}In the world of manufacturing, precision and quality are the driving forces behind successful production processes. One essential component that plays a crucial role in achieving these benchmarks is the aluminum casting die. This vital tool is utilized in the production of a wide range of products, from automotive parts to consumer goods. At {}, the use of aluminum casting dies has been instrumental in the company's success and reputation as a leading manufacturer in the industry.With a focus on innovation and cutting-edge technology, {} has consistently pushed the boundaries of what is possible in the manufacturing sector. The company has invested heavily in state-of-the-art machinery and equipment, including advanced aluminum casting dies, to ensure that their products meet the highest standards of quality and precision.The aluminum casting die is a specialized tool that is used to create complex and intricate parts through the process of aluminum die casting. This method involves injecting molten aluminum into the die under high pressure, allowing it to solidify and take the shape of the mold. The result is a finished product that exhibits exceptional dimensional accuracy and surface finish, making it ideal for a wide range of applications.One of the key advantages of using aluminum casting dies is the ability to produce high-quality parts at a rapid pace. This increased efficiency allows {} to fulfill large orders in a timely manner, meeting the demands of their clients and maintaining a competitive edge in the market. Furthermore, the durability and longevity of aluminum casting dies ensure that they can withstand the rigors of high-volume production, making them a cost-effective solution for manufacturing operations.The expertise and skill of {}'s team of engineers and technicians are evident in the meticulous design and construction of their aluminum casting dies. Each die is customized to meet the specific requirements of the product being manufactured, ensuring that every detail is precision-engineered to exact specifications. This attention to detail is a testament to {}'s commitment to delivering superior products that exceed the expectations of their customers.In addition to their commitment to quality, {} also places a strong emphasis on sustainability and environmental responsibility. Aluminum casting is a highly efficient and recyclable process, making it an eco-friendly choice for manufacturing. By utilizing aluminum casting dies, {} is able to minimize waste and reduce their environmental impact, aligning with their dedication to corporate social responsibility and sustainable practices.Looking ahead, {} continues to explore new opportunities for advancement in the realm of aluminum casting die technology. By staying at the forefront of industry trends and developments, the company is poised to further enhance their capabilities and expand their offerings to meet the evolving needs of their customers.In conclusion, aluminum casting dies play a pivotal role in the manufacturing operations at {}. The company's investment in cutting-edge technology and unwavering dedication to quality has positioned them as a leader in the industry. With a focus on innovation, sustainability, and customer satisfaction, {} is well-positioned to continue delivering excellence in the realm of aluminum die casting for years to come.

Best Practices for Aluminum Slab Casting: What You Need to Know

Aluminum Slab Casting: Revolutionizing the Aluminum IndustryThe aluminum industry has experienced significant growth and innovation in recent years, with advancements in technology and processes leading to more efficient and sustainable production methods. One such innovation that has gained widespread attention is Aluminum Slab Casting, a groundbreaking process that has the potential to revolutionize the way aluminum is produced.The process of Aluminum Slab Casting involves the continuous casting of aluminum slabs using advanced casting technology. This method allows for the production of high-quality aluminum slabs with precise dimensions and exceptional surface quality. This not only improves the overall quality of the aluminum produced but also reduces waste and energy consumption, making it a more sustainable and cost-effective solution for the industry.One company that has been at the forefront of this innovation is {}. With over 50 years of experience in the aluminum industry, {} has been a pioneer in the development of advanced casting technologies. Their state-of-the-art facilities and cutting-edge equipment have enabled them to produce aluminum products of the highest quality, setting industry standards and exceeding customer expectations.The introduction of Aluminum Slab Casting has further solidified {}'s position as a leader in the aluminum industry. This innovative casting process has allowed them to expand their product offerings and enter new markets, driving growth and success for the company. By embracing advanced technologies and investing in research and development, {} has demonstrated a commitment to staying ahead of the curve and delivering innovative solutions to the market.The benefits of Aluminum Slab Casting are manifold, with its impact being felt across the entire aluminum supply chain. By producing high-quality aluminum slabs with improved surface finish and dimensional accuracy, this process enables manufacturers to reduce machining requirements and minimize material waste, ultimately leading to cost savings and improved efficiency. Additionally, the use of continuous casting technology allows for greater flexibility in production, as well as the ability to produce a wider range of alloys and custom sizes to meet customer needs.In addition to its production benefits, Aluminum Slab Casting also has a positive environmental impact. By reducing energy consumption and waste generation, this process aligns with the industry's sustainability goals, making it a more eco-friendly alternative to traditional casting methods. As the global focus on sustainability and environmental responsibility continues to grow, the adoption of Aluminum Slab Casting is expected to gain further momentum, driving industry-wide change and promoting a more sustainable future for the aluminum sector.Looking ahead, the future of Aluminum Slab Casting appears promising, with continued advancements and refinements expected to further enhance its capabilities and benefits. As the industry continues to evolve, it is likely that more companies will adopt this innovative casting process, driving increased efficiency and productivity across the aluminum supply chain.As a leader in the aluminum industry, {} is well-positioned to capitalize on the opportunities presented by Aluminum Slab Casting. With their track record of innovation and commitment to excellence, they are poised to continue driving industry advancements and setting new standards for aluminum production. As the industry looks to the future, it is clear that Aluminum Slab Casting will play a pivotal role in shaping the next chapter of the aluminum industry, with {} leading the way towards a more sustainable and efficient future.