Durable and Versatile: The Benefits of Cast Iron Metal

By:Admin

Founded in 1998, Cast Iron Metal has continuously strived to provide its customers with the best quality products while maintaining a strong commitment to sustainability and environmental responsibility. The company's dedication to excellence has earned it a reputation for reliability and durability, making it the go-to choice for many industries, including construction, automotive, and manufacturing.

One of the key factors that set Cast Iron Metal apart from its competitors is its state-of-the-art production facilities, which are equipped with the latest technology and machinery. This allows the company to efficiently produce a wide range of metal products, including cast iron pipes, fittings, and other specialty items, to meet the diverse needs of its customers.

In addition to its advanced production capabilities, Cast Iron Metal also prides itself on its stringent quality control measures. Every product that leaves the company's facilities undergoes a rigorous inspection process to ensure that it meets the highest standards of quality and performance. This commitment to quality has enabled Cast Iron Metal to build a loyal customer base that relies on its products for their most demanding applications.

Furthermore, Cast Iron Metal is committed to sustainability and environmental stewardship. The company has implemented various eco-friendly practices in its operations, such as recycling and waste reduction initiatives, to minimize its environmental footprint. Additionally, Cast Iron Metal continuously seeks opportunities to improve its energy efficiency and reduce its greenhouse gas emissions, demonstrating its dedication to a cleaner, greener future.

The company's commitment to excellence and sustainability has not gone unnoticed, as it has received numerous accolades and certifications for its outstanding performance in the industry. Cast Iron Metal's products are known for their superior strength, durability, and longevity, making them the preferred choice for many customers around the world.

Recently, Cast Iron Metal unveiled its latest innovation, the [Product Name], which promises to revolutionize the industry. This groundbreaking product is the result of extensive research and development, and it showcases the company's dedication to innovation and improvement. The [Product Name] boasts advanced features and capabilities that make it stand out from traditional metal products, setting a new standard for performance and reliability.

Moreover, Cast Iron Metal has also expanded its global footprint, establishing partnerships and distribution channels in key markets around the world. This strategic expansion has allowed the company to reach more customers and deliver its exceptional products to a wider audience, further solidifying its position as a leader in the metal manufacturing sector.

As Cast Iron Metal continues to grow and evolve, it remains committed to its core values of quality, innovation, and sustainability. The company's unwavering dedication to excellence has positioned it as a trailblazer in the industry, and its future looks brighter than ever. Customers can expect nothing but the best from Cast Iron Metal as it continues to push the boundaries of what is possible in the world of metal manufacturing.

Company News & Blog

High-quality Welding Services for Aluminium Fabrication at Gearbox

Gearbox Welding Aluminium is a leading company in the field of aluminium welding, specialising in providing high-quality welding solutions for a wide range of industries. With a strong focus on innovation and efficiency, Gearbox Welding Aluminium has established itself as a trusted partner for businesses looking to improve their welding processes.The company’s extensive experience and expertise in welding aluminium make it a go-to choice for companies seeking precision welding solutions. Whether it’s automotive, aerospace, or manufacturing, Gearbox Welding Aluminium has the skills and technology to handle complex welding projects with ease.At Gearbox Welding Aluminium, the team is dedicated to delivering exceptional results for their clients. They understand the unique characteristics of aluminium and the challenges that come with welding this material. As a result, they have developed advanced welding techniques and processes to ensure the highest quality welds for their customers.One of the key factors that sets Gearbox Welding Aluminium apart from the competition is their commitment to innovation. The company invests heavily in research and development to stay ahead of the curve and continuously improve their welding techniques. This dedication to innovation allows them to offer cutting-edge solutions that meet the evolving needs of their clients.In addition to their technical expertise, Gearbox Welding Aluminium also prioritises customer service. They work closely with their clients to understand their specific requirements and provide tailored solutions that meet their needs. This collaborative approach has earned the company a reputation for reliability and professionalism in the industry.Gearbox Welding Aluminium is also known for its state-of-the-art facilities and equipment. The company has made significant investments in the latest welding technology, ensuring that they have the tools and resources to take on even the most challenging welding projects. This commitment to staying at the forefront of the industry positions Gearbox Welding Aluminium as a leader in the field of aluminium welding.In a recent development, Gearbox Welding Aluminium has announced the launch of a new welding process that promises to revolutionise the way aluminium is welded. This innovative welding technique has been developed in response to the growing demand for high-quality, cost-effective welding solutions for aluminium.The new welding process, which has been patented by Gearbox Welding Aluminium, is expected to offer significant improvements in efficiency and quality compared to traditional welding methods. By harnessing the latest advancements in welding technology, the company aims to set a new standard for aluminium welding and provide their clients with a competitive edge in their respective industries.The introduction of this groundbreaking welding process is a testament to Gearbox Welding Aluminium's ongoing commitment to innovation and excellence. The company’s ability to develop and implement cutting-edge welding solutions underscores its position as a leader in the industry.To support the launch of the new welding process, Gearbox Welding Aluminium has also expanded its team of welding experts and invested in additional training and resources. This ensures that they have the expertise and capacity to meet the growing demand for their services and deliver exceptional results for their clients.As Gearbox Welding Aluminium continues to push the boundaries of what is possible in aluminium welding, the company has positioned itself as a trusted partner for businesses looking to elevate their welding capabilities. With a focus on innovation, efficiency, and customer service, Gearbox Welding Aluminium is poised to lead the way in the future of aluminium welding.

Top Car Interior Parts to Upgrade Your Vehicle

Car Interior Parts Manufacturer {company name disguised} Continues to Expand Its Reach in the Global Market{City, Country, Date} - {Company name disguised}, a leading manufacturer of car interior parts, has been consistently expanding its reach in the global market, offering high-quality products to clients around the world. With its focus on innovation, customer service, and high-quality manufacturing processes, {company name disguised} has become a household name in the automotive industry.Founded in 2006, {company name disguised} has been working tirelessly to meet the increasing demands of the automotive industry. With its state-of-the-art manufacturing facilities and highly skilled workforce, the company produces a wide range of car interior parts, including car seats, door panels, dashboards, and steering wheels.{Company name disguised} takes pride in its commitment to innovation, constantly striving to enhance the design and functionality of its products. The company's in-house research and development team meticulously tests and refines its products to ensure they meet the highest quality standards. Through its continued efforts in research and development, {company name disguised} has been able to introduce a range of innovative products to the market, including 3D-printed car seats, heated steering wheels, and custom-designed upholstery.In addition to its commitment to innovation, {company name disguised} places a strong emphasis on customer service. The company's skilled workforce is trained to provide personalized service to clients, ensuring that their needs are met with efficiency and professionalism. By maintaining close relationships with its clients, {company name disguised} has been able to stay ahead of the competition and maintain its position as a leading manufacturer of car interior parts.With its state-of-the-art manufacturing facilities and commitment to quality and innovation, {company name disguised} has become a trusted partner for automotive manufacturers around the world. The company's products are used by some of the biggest names in the automotive industry, including BMW, Mercedes-Benz, and Audi, among others.Despite the challenges posed by the COVID-19 pandemic, {company name disguised} has continued to expand its reach in the global market. The company has recently signed several major contracts with automotive manufacturers in North America, Europe, and Asia, further strengthening its position as a leading supplier of car interior parts.Looking ahead, {company name disguised} is committed to maintaining its focus on innovation, customer service, and quality manufacturing processes. By staying at the forefront of the latest trends and technologies in the automotive industry, the company is well-positioned to continue its growth and success in the years to come.About {company name disguised}:{Company name disguised} is a leading manufacturer of car interior parts, founded in {year}. With its state-of-the-art manufacturing facilities and highly skilled workforce, the company produces a wide range of car interior parts, including car seats, door panels, dashboards, and steering wheels. The company is committed to innovation, customer service, and quality manufacturing processes, and serves clients around the world, including some of the biggest names in the automotive industry.

Durable and Strong Cast Iron: A Closer Look at Its Benefits

White Cast Iron, a leading manufacturer in the iron and steel industry, has been making waves with its high-quality and durable products. With a strong focus on innovation and customer satisfaction, {company name} has established itself as a frontrunner in the industry.White Cast Iron prides itself on its ability to produce cast iron products that are not only aesthetically pleasing but also highly functional. The company's commitment to quality is evident in the meticulous attention to detail that goes into every product, ensuring that customers receive the best value for their money.One of the key factors that sets White Cast Iron apart from its competitors is its state-of-the-art manufacturing facility. Equipped with the latest technology and machinery, the facility enables the company to consistently produce products that meet the highest industry standards.In addition to its manufacturing capabilities, White Cast Iron also places a strong emphasis on research and development. The company invests heavily in R&D to stay ahead of the curve and continuously improve its products. This commitment to innovation has allowed White Cast Iron to introduce cutting-edge designs and features that set its products apart from the competition.Furthermore, White Cast Iron is dedicated to sustainability and environmentally-friendly practices. The company strives to minimize its environmental impact by using eco-friendly materials and implementing energy-efficient production processes. This commitment to sustainability has not only earned White Cast Iron a positive reputation but has also positioned the company as a leader in the global effort towards sustainable manufacturing.White Cast Iron's dedication to quality, innovation, and sustainability has not gone unnoticed. The company has received numerous accolades and certifications for its products and practices, further solidifying its position as an industry leader. Customers can trust that they are getting the best when they choose White Cast Iron for their iron and steel needs.In addition to its commitment to excellence, White Cast Iron also prioritizes customer satisfaction. The company takes great pride in providing exceptional customer service and support, ensuring that customers receive the assistance and guidance they need at every step of the way.Looking ahead, White Cast Iron shows no signs of slowing down. The company is constantly exploring new opportunities for growth and expansion, both domestically and internationally. With a strong foundation built on quality, innovation, and sustainability, White Cast Iron is well-positioned to continue its success well into the future.Overall, White Cast Iron's dedication to producing high-quality, innovative, and sustainable cast iron products has solidified its position as a leader in the industry. With a strong commitment to excellence and customer satisfaction, the company is poised for continued success and growth in the years to come.

Molding Sand for Metal Casting: What You Need to Know

[Company Name] Introduces Revolutionary Molding Sand for Metal CastingMetal casting has been a crucial industrial process for centuries, allowing for the creation of complex and durable metal parts for a wide range of applications. One of the key elements in metal casting is the molding sand, which is used to create the molds into which molten metal is poured. With the introduction of a revolutionary new molding sand by [Company Name], the metal casting industry is set to undergo a significant transformation.[Company Name] has a long-standing reputation for innovation and excellence in the field of industrial materials. With a history dating back to [year], the company has consistently pushed the boundaries of what is possible in various industrial processes. The introduction of their new molding sand for metal casting is a continuation of this tradition of innovation.The new molding sand, developed after years of research and development, offers several distinct advantages over traditional molding sands. Its unique composition and properties make it significantly more durable and heat-resistant, allowing for the production of more intricate and high-quality metal parts. Additionally, the new molding sand is more environmentally friendly, with reduced emissions and waste compared to traditional sand.One of the most significant benefits of the new molding sand is its superior stability and consistency. This allows for more precise and reliable metal casting, leading to higher-quality finished products. In addition, the new molding sand is easier to work with, saving time and labor costs for manufacturers.The introduction of this new molding sand has the potential to revolutionize the metal casting industry. Manufacturers will be able to produce metal parts with greater efficiency, lower costs, and higher quality than ever before. This will have a ripple effect throughout the industrial sector, leading to improved products and processes across a wide range of industries.In addition to the molding sand itself, [Company Name] will also be offering comprehensive support and training for manufacturers looking to integrate the new sand into their metal casting processes. This will ensure that the full potential of the new molding sand is realized and that manufacturers are able to take full advantage of its benefits.The introduction of this new molding sand is yet another example of [Company Name]'s commitment to driving innovation and progress in the industrial sector. By consistently pushing the boundaries of what is possible, [Company Name] has established itself as a leader in the development of advanced materials and processes.As the metal casting industry embraces this revolutionary new molding sand, the potential for new and improved metal parts is virtually limitless. With more durable, heat-resistant, and environmentally friendly molding sand, manufacturers will be able to push the boundaries of what is possible in metal casting, leading to a new era of innovation and progress in the industrial sector.In conclusion, the introduction of the new molding sand by [Company Name] represents a significant leap forward for the metal casting industry. With its unique composition and properties, the new molding sand offers numerous advantages over traditional sands, including greater durability, heat resistance, and environmental friendliness. As manufacturers begin to integrate this new molding sand into their processes, the potential for innovation and progress in the metal casting industry is truly exciting.

Complete Guide to Hollow Metal Casting: Process, Benefits, and Applications

Hollow metal casting is the process of creating metal parts and components with hollow interiors. It is a widely used method in the manufacturing industry for producing a variety of products, including automotive parts, industrial equipment, and consumer goods. This process involves pouring molten metal into a mold with a hollow cavity and allowing it to solidify, resulting in a finished product with a hollow interior.In the world of hollow metal casting, one company stands out for its expertise and innovative approach to this manufacturing process. With a wealth of experience and a commitment to quality, {} has established itself as a leader in the field of hollow metal casting. The company offers a comprehensive range of services, from design and prototyping to production and finishing, making it a one-stop shop for all hollow metal casting needs.{}'s state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to consistently deliver high-quality casting solutions to their clients. Their team of skilled engineers and technicians work closely with customers to understand their unique requirements and develop customized casting solutions that meet and exceed expectations.One of the key advantages of {}'s hollow metal casting process is its ability to produce complex shapes and intricate designs with a high level of precision. This makes it an ideal choice for industries such as aerospace, defense, and medical, where component intricacy and accuracy are critical.In addition to its technical expertise, {} is also committed to sustainability and environmentally friendly practices. The company has implemented various initiatives to reduce its environmental impact, such as investing in energy-efficient equipment and using recycled materials whenever possible.With a strong focus on continuous improvement and innovation, {} is constantly exploring new techniques and materials to further enhance its hollow metal casting capabilities. This dedication to research and development has enabled the company to stay ahead of the curve and remain at the forefront of the industry.Furthermore, {}'s commitment to quality is reflected in its rigorous quality control processes. Every step of the casting process is carefully monitored and inspected to ensure that the finished products meet the highest standards of quality and performance.As a testament to its excellence, {} has earned various certifications and accolades for its commitment to quality and customer satisfaction. This includes ISO certification, which is a testament to the company's adherence to international standards for quality management.In conclusion, {} is a leading provider of hollow metal casting solutions, known for its technical expertise, commitment to quality, and dedication to sustainability. With a focus on innovation and continuous improvement, the company is well-positioned to meet the evolving needs of the manufacturing industry and continue its success as a trusted partner for hollow metal casting solutions.

High-Quality Aluminium Gravity Casting for Diverse Applications

Aluminium Gravity Casting has been a cornerstone of manufacturing for years, and it has only gotten better with advancements in technology and production processes. This type of casting is ideal for creating high-quality, complex parts that require tight tolerances and excellent surface finishes. With its ability to produce intricate designs and consistent results, Aluminium Gravity Casting is a preferred choice for numerous industries, including automotive, aerospace, and consumer goods.One company that has made a name for itself in the Aluminium Gravity Casting industry is {}. With over 20 years of experience, {} has established itself as a leading manufacturer and supplier of high-quality aluminium gravity castings. The company is known for its commitment to precision, quality, and innovation, and it has earned the trust and respect of customers around the world.{} specializes in producing a wide range of aluminium gravity castings, including automotive components, industrial parts, and consumer goods. The company's state-of-the-art manufacturing facilities are equipped with advanced technology and machinery to ensure the highest level of quality and efficiency. With a team of skilled engineers and technicians, {} is capable of meeting the most demanding requirements and delivering superior products that meet or exceed customer expectations.The company's dedication to quality is evident in its strict adherence to industry standards and regulations. {} employs stringent quality control measures throughout the production process to ensure that every casting meets the highest standards of performance and durability. From raw material inspection to final product testing, {} leaves no stone unturned in its quest for excellence.In addition to its commitment to quality, {} is also focused on sustainability and environmental responsibility. The company employs eco-friendly practices and technologies to minimize its environmental impact and reduce waste. By utilizing recycling and energy-saving initiatives, {} strives to contribute to a cleaner and more sustainable planet.{}'s dedication to innovation and continuous improvement has allowed the company to stay ahead of the competition and remain a trusted partner for its customers. The company invests in research and development to explore new technologies and processes that can further enhance its capabilities and offer more value to its clients. By staying at the forefront of technological advancements, {} is able to provide cutting-edge solutions that meet the evolving needs of the industries it serves.With a strong focus on customer satisfaction, {} places great emphasis on building long-term relationships with its clients. The company works closely with customers to understand their specific requirements and provide tailored solutions that meet their unique needs. By offering comprehensive support and a collaborative approach, {} has earned a reputation for reliability, professionalism, and integrity.As a testament to its success and industry leadership, {} has received numerous accolades and certifications for its outstanding performance and quality. The company's dedication to excellence and customer satisfaction has earned it recognition as a trusted and dependable supplier of aluminium gravity castings.In conclusion, Aluminium Gravity Casting is a vital process for many industries, and {} has established itself as a leading force in the manufacturing of high-quality aluminium gravity castings. With its commitment to precision, quality, innovation, and sustainability, {} continues to set the bar for excellence in the industry. As the company looks to the future, it remains dedicated to meeting the evolving needs of its customers and driving the industry forward with its cutting-edge solutions and unwavering dedication to excellence.

High-Quality Brake Accessories for Cars - Everything You Need to Know

Car Brake Accessories, a leading supplier in the automotive industry, is making waves with their innovative and high-quality brake accessories. The company, which has been in operation for over 20 years, has established itself as a trusted and reliable source for top-of-the-line brake accessories for all types of vehicles.Car Brake Accessories is known for its commitment to providing customers with the best products on the market. Their extensive range of brake accessories includes brake pads, brake rotors, brake calipers, brake lines, brake drums, and much more. Their products are designed to meet the highest industry standards and are rigorously tested to ensure optimal performance and durability.The company has a team of experienced and knowledgeable professionals who are dedicated to delivering exceptional customer service and technical support. They understand the importance of having reliable and efficient brake accessories, and they work tirelessly to ensure that their customers have access to the best products available.In addition to their commitment to quality, Car Brake Accessories also places a strong emphasis on innovation. They are constantly researching and developing new products and technologies to stay ahead of the curve in the ever-evolving automotive industry. This dedication to innovation has allowed them to stay at the forefront of the market and maintain their position as a leader in the industry.One of the company's most popular products is its premium brake pads, which are designed to deliver superior performance and reliability. These brake pads are manufactured using high-quality materials and advanced production techniques to ensure maximum stopping power and long-lasting durability. They are also engineered to reduce noise and vibration, providing a smooth and quiet driving experience.Another standout product from Car Brake Accessories is its performance brake rotors. These rotors are designed to withstand the high demands of performance driving, delivering exceptional braking performance and heat dissipation. They are available in a variety of styles and sizes to fit a wide range of vehicles, making them a top choice for automotive enthusiasts and professional drivers alike.The company also offers a comprehensive range of brake calipers, which are essential components of a vehicle's braking system. Their calipers are designed to provide optimal clamping force and heat dissipation, ensuring reliable and consistent braking performance in all driving conditions. They are available in various colors and finishes, allowing customers to customize their vehicles while also enhancing safety and performance.Car Brake Accessories is also known for its high-quality brake lines, which are essential for transmitting hydraulic pressure and fluid to the braking system. Their brake lines are constructed with durable materials and are rigorously tested to withstand extreme temperatures and pressures, ensuring reliable performance and safety.In addition to these core products, Car Brake Accessories also offers a wide range of other brake accessories, including brake drums, brake hardware, brake fluid, and more. Their comprehensive product line allows customers to find everything they need for their brake system in one convenient location.Customers can also take advantage of the company's easy online ordering system, allowing them to quickly and efficiently purchase the brake accessories they need. Car Brake Accessories is committed to providing a seamless and hassle-free shopping experience for its customers, ensuring that they can get the products they need as quickly and easily as possible.Overall, Car Brake Accessories is a company that is dedicated to providing the highest quality brake accessories for all types of vehicles. With a strong focus on innovation, reliability, and customer service, they have established themselves as a trusted and respected source in the automotive industry. Whether you're a professional driver, automotive enthusiast, or everyday commuter, Car Brake Accessories has the products you need to keep your vehicle's braking system performing at its best.

High-quality Aluminum Alloy Investment Casting: A Complete Guide

Aluminum Alloy Investment Casting: Paving the Way for Advanced Engineering SolutionsInvestment casting is a manufacturing process that has been used for centuries to create metal components with intricate shapes and intricate details. In recent years, the use of aluminum alloys in investment casting has gained popularity due to their lightweight, high strength, and corrosion-resistant properties. One company that has been at the forefront of this trend is {Company Name}.{Company Name} is a leading manufacturer of aluminum alloy investment castings, serving a wide range of industries including aerospace, automotive, defense, and medical. The company has built a reputation for producing high-quality, complex parts with tight tolerances and superior surface finishes. Their expertise in aluminum alloy investment casting has enabled them to offer innovative solutions to their customers’ most challenging engineering problems.One of the key advantages of aluminum alloy investment casting is its ability to produce parts with thin walls, complex geometries, and fine details. This makes it an ideal choice for applications where weight reduction and high performance are crucial. For example, in the aerospace industry, aluminum alloy investment castings are used to manufacture aircraft components such as engine mounts, wing ribs, and structural fittings. The lightweight nature of aluminum alloys helps to reduce overall aircraft weight, leading to improved fuel efficiency and lower operating costs.In the automotive sector, aluminum alloy investment castings are utilized for various applications such as transmission housings, engine parts, and suspension components. The use of aluminum alloys in these components not only helps to reduce vehicle weight but also enhances overall performance and fuel efficiency. Furthermore, the corrosion-resistant properties of aluminum alloys make them an attractive choice for components that are exposed to harsh environmental conditions.The defense industry also benefits from the use of aluminum alloy investment castings in the manufacturing of components for military vehicles, weapons systems, and communications equipment. The lightweight and high-strength characteristics of aluminum alloys make them an ideal material for meeting the stringent requirements of defense applications.Moreover, in the medical industry, aluminum alloy investment castings are used to produce critical components for medical devices and equipment. The biocompatibility of aluminum alloys, along with their superior mechanical properties, makes them suitable for a wide range of medical applications.In addition to its widespread use in various industries, aluminum alloy investment casting offers several other advantages such as cost-effectiveness, design flexibility, and the ability to produce near-net-shaped parts, reducing the need for secondary machining operations. With the advancement of casting technology and computer-aided design (CAD), complex shapes and intricate details can be achieved with high precision, enabling manufacturers to produce parts that were once deemed impossible through traditional manufacturing processes.As a leader in aluminum alloy investment casting, {Company Name} has continued to invest in state-of-the-art equipment, advanced materials, and process optimization techniques. This has allowed them to expand their capabilities and produce components that meet the most demanding requirements of their customers. The company’s experienced team of engineers, metallurgists, and manufacturing experts work closely with customers from the initial design phase through to the final production, ensuring that the end product meets the highest quality standards.As the demand for lightweight, high-performance components continues to grow across industries, the use of aluminum alloy investment casting is expected to play a significant role in the future of engineering solutions. With its unparalleled capability to produce complex, high-quality parts with a competitive edge, {Company Name} is well-positioned to meet the evolving needs of its customers and contribute to the advancement of engineering and manufacturing technologies.In conclusion, aluminum alloy investment casting has opened up new possibilities for designing and producing advanced components that deliver superior performance, lightweight design, and cost-effectiveness. With {Company Name} leading the way in this field, the potential for innovation and advancement in engineering solutions is indeed promising.

Top Benefits of Aluminum Gravity Die Casting for Manufacturing

Aluminum Gravity Die Casting is a popular manufacturing process that involves the use of a permanent mold made of steel or graphite to produce high-quality aluminum parts. This process is known for its ability to produce complex and intricate parts with excellent surface finishes and dimensional accuracy. The Aluminum Gravity Die Casting process is widely used in industries such as automotive, aerospace, and electronics due to its ability to produce parts with excellent mechanical properties and high strength-to-weight ratio.With the increasing demand for aluminum components in various industries, the need for high-quality Aluminum Gravity Die Casting services has become more important than ever. One company that has made a name for itself in this field is {company's name}, a leading provider of Aluminum Gravity Die Casting solutions.Established over a decade ago, {company's name} has gained a solid reputation for its expertise in Aluminum Gravity Die Casting. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery to ensure the production of high-quality aluminum parts that meet the highest industry standards. {company's name} offers a wide range of Aluminum Gravity Die Casting services, including prototyping, tooling design, and full-scale production.One of the key advantages of choosing {company's name} for Aluminum Gravity Die Casting is their team of highly skilled engineers and technicians. With years of experience in the field, they are capable of providing innovative solutions to even the most complex casting challenges. {company's name} is committed to delivering superior products and services to their clients, and their dedication to quality is evident in every step of the manufacturing process.In addition to their expertise in Aluminum Gravity Die Casting, {company's name} is also known for their commitment to sustainability and environmental responsibility. The company has implemented several initiatives to minimize their environmental impact, including the use of energy-efficient equipment and recycling of all scrap materials. {company's name} is dedicated to maintaining the highest environmental standards while continuing to provide exceptional Aluminum Gravity Die Casting services.With their dedication to quality, innovation, and environmental responsibility, {company's name} has earned the trust and satisfaction of their clients. Their customer base includes some of the most reputable companies in the automotive, aerospace, and electronics industries, who rely on {company's name} for their Aluminum Gravity Die Casting needs.In conclusion, Aluminum Gravity Die Casting is a crucial manufacturing process that is essential for producing high-quality aluminum parts with precision and efficiency. {company's name} has established itself as a leader in the field of Aluminum Gravity Die Casting, offering innovative solutions and superior services to their clients. With their commitment to quality, innovation, and sustainability, {company's name} is well-positioned to meet the growing demand for high-quality Aluminum Gravity Die Casting services and continue to be a trusted partner for their clients in various industries.

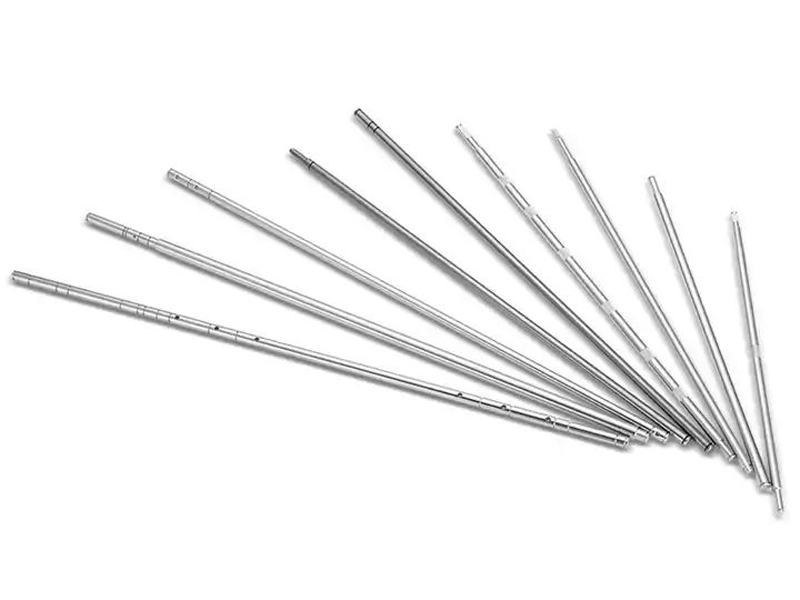

High-Quality Spun Cast Stainless Steel: The Latest in Metal Technology

Spun Cast Stainless Steel, the revolutionary material that is taking the industry by storm, is now being promoted by a leading company in the field of metal production. {} has been at the forefront of manufacturing high-quality metal products for multiple industries, and their introduction of Spun Cast Stainless Steel is set to revolutionize the market even further.Spun Cast Stainless Steel is a unique material that offers a combination of superior strength, durability, and corrosion resistance. It is produced using a specialized spinning process that results in a seamless and dense metal structure, making it ideal for a wide range of applications. From industrial machinery to aerospace components, Spun Cast Stainless Steel has been proven to outperform traditional metal alloys in terms of performance and longevity.{} has recognized the potential of Spun Cast Stainless Steel early on and has invested heavily in its production capabilities. With state-of-the-art manufacturing facilities and a team of experienced engineers and metallurgists, the company has been able to produce Spun Cast Stainless Steel products that meet the highest industry standards. This dedication to quality has earned {} a reputation as a trusted supplier of premium metal products.The introduction of Spun Cast Stainless Steel by {} has already garnered significant attention within the industry. Many companies are now turning to this advanced material for their metal component needs, as it offers a multitude of benefits over traditional alloys. From increased corrosion resistance to superior mechanical properties, Spun Cast Stainless Steel is quickly becoming the material of choice for demanding applications.In addition to its performance benefits, Spun Cast Stainless Steel also offers cost savings in the long run. Its extended lifespan and reduced maintenance requirements make it a more economical choice compared to other metals. This has further solidified {}'s position as a leading supplier of high-performance metal products, as they continue to offer innovative solutions that deliver tangible value to their customers.One of the key advantages of Spun Cast Stainless Steel is its versatility. {} has been able to develop a wide range of products using this material, including seamless tubes, pipes, and custom components. This flexibility ensures that customers can find the right solution for their specific needs, whether it be in the automotive, chemical, or oil and gas industry.The success of {} and their introduction of Spun Cast Stainless Steel is a testament to their commitment to innovation and excellence. By embracing new technologies and materials, they have been able to stay ahead of the competition and provide their customers with cutting-edge solutions that deliver outstanding performance and reliability.Looking ahead, {} is poised to further expand its range of Spun Cast Stainless Steel products, as they continue to push the boundaries of what is possible with this remarkable material. With a focus on research and development, they are set to unveil even more advanced offerings that will set new standards in the industry.As the demand for high-performance, corrosion-resistant, and durable metal products continues to grow, {}'s introduction of Spun Cast Stainless Steel has positioned them as a company to watch in the industry. Their commitment to quality and innovation has set them apart, and their dedication to providing superior solutions to their customers ensures that they will remain a trusted partner for many years to come.