High-Quality Aluminium Alloy Investment Casting: What You Need to Know

By:Admin

One company that has been at the forefront of Aluminium Alloy Investment Casting is {} (). With over 30 years of experience in the industry, the company has established itself as a leader in the field of precision casting. Their state-of-the-art facilities and cutting-edge technology allow them to produce components that meet the highest standards of quality and performance.

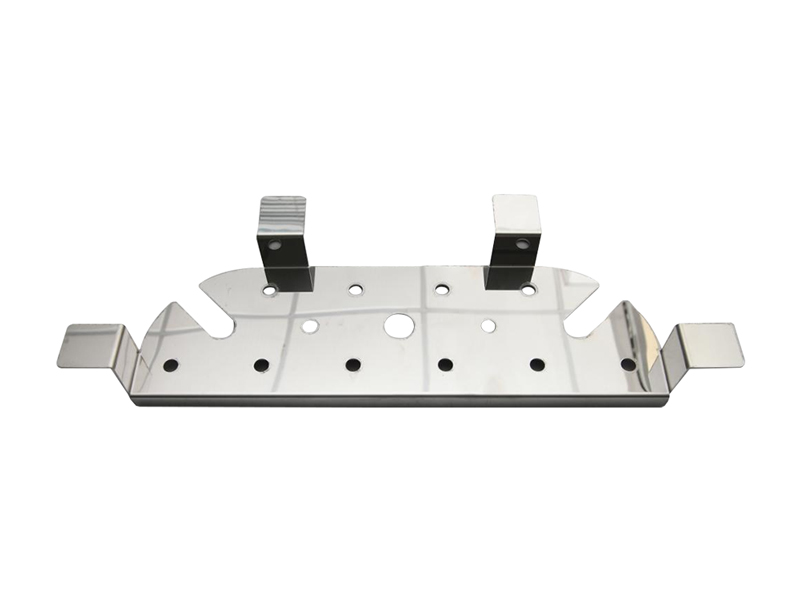

The process of Aluminium Alloy Investment Casting begins with the creation of a wax pattern, which is then coated with a ceramic shell to form a mold. Once the mold is complete, it is heated to remove the wax, leaving behind a cavity in the shape of the desired part. Molten aluminium alloy is then poured into the mold, where it solidifies to form the final component. This process allows for the production of parts with intricate details and thin walls, making it ideal for a wide range of applications.

{}'s expertise in Aluminium Alloy Investment Casting has allowed them to serve a diverse customer base, including aerospace, automotive, and medical industries. Their components can be found in critical systems such as aircraft engines, automotive transmissions, and medical devices. The company's commitment to quality and precision has earned them a reputation for excellence, and they continue to push the boundaries of what is possible with investment casting.

One of the key advantages of Aluminium Alloy Investment Casting is its ability to produce parts with complex geometries and thin walls. This makes it an attractive option for designers and engineers looking to create lightweight components with intricate details. Additionally, the process allows for the production of parts with excellent surface finishes, reducing the need for additional finishing processes.

In addition to their expertise in Aluminium Alloy Investment Casting, {} offers a range of value-added services to their customers. These include engineering support, rapid prototyping, and finishing services such as machining, heat treatment, and coatings. This comprehensive approach allows them to provide turnkey solutions to their customers, streamlining the production process and reducing lead times.

The company's commitment to continuous improvement and investment in the latest technology has allowed them to stay ahead of the competition in the field of Aluminium Alloy Investment Casting. They have recently expanded their capabilities with the addition of new equipment and facilities, allowing them to take on larger and more complex projects. Additionally, their dedication to quality and customer satisfaction has earned them numerous certifications and accolades, solidifying their position as a key player in the industry.

As the demand for lightweight, durable, and high-performance components continues to grow, Aluminium Alloy Investment Casting is poised to play a critical role in the manufacturing industry. With {}'s expertise and capabilities, they are well-positioned to meet the needs of their customers and continue to push the boundaries of what is possible with investment casting. Their commitment to innovation and excellence sets them apart as a leader in the field, and they are poised to continue their success in the years to come.

Company News & Blog

Optimize Your Vehicle's Performance with High-Quality Shaft Car Parts

Shaft Car Part Announces New Product Innovation[Company Name], a leading automotive parts manufacturer and supplier, is thrilled to announce the launch of their latest innovative product, the Shaft Car Part. This groundbreaking development is set to revolutionize the automotive industry, providing car owners with a reliable and efficient solution for their vehicle's performance.With an established reputation for excellence and a commitment to delivering quality products, [Company Name] is known for its dedication to customer satisfaction. Leveraging years of industry expertise, the company continues to stay ahead of the competition by consistently introducing new and cutting-edge products.The Shaft Car Part is set to make its mark with its advanced design and state-of-the-art technology. Manufactured using high-quality materials and precision engineering, this innovative product offers car owners the promise of improved performance, enhanced durability, and a smoother driving experience.Designed to ensure optimal power transmission and reliability, the Shaft Car Part is built to withstand the rigorous demands of everyday use. Its robust construction enhances the vehicle's drivetrain system, resulting in increased torque and improved acceleration. Additionally, the part's enhanced durability minimizes the risk of breakdowns and costly repairs, providing car owners with peace of mind and long-lasting performance.One of the key features of the Shaft Car Part is its compatibility with a wide range of car models and makes. This universal adaptability ensures that car owners can benefit from this innovative product regardless of the vehicle they own. This flexibility further demonstrates [Company Name]'s commitment to providing accessible solutions for all customers, regardless of their automotive preferences.Furthermore, the Shaft Car Part boasts an easy installation process, making it ideal for both professional mechanics and car enthusiasts. Its user-friendly design allows for hassle-free integration into the existing vehicle system, reducing downtime and minimizing labor costs. This accessibility is especially valuable to customers who prefer to work on their own cars or those who rely on quick and efficient servicing.The launch of the Shaft Car Part reinforces [Company Name]'s ongoing commitment to research and development. The company invests heavily in state-of-the-art facilities and employs a dedicated team of engineers and technicians to ensure continuous product improvement and innovation. By actively listening to customer feedback and striving for excellence in their products, [Company Name] aims to meet and exceed the ever-evolving needs of the automotive industry."We are incredibly excited to introduce the Shaft Car Part to the market," said [Company Name]'s CEO. "This is a significant milestone for us, and it demonstrates our commitment to delivering exceptional automotive parts that enhance the driving experience. Our team has worked tirelessly to develop a product that not only meets the highest quality standards but also offers increased performance and reliability to our valued customers."Customers can expect to find the Shaft Car Part available for purchase at authorized dealers and online retailers starting next month. [Company Name] also offers a comprehensive warranty program for added customer assurance.In conclusion, [Company Name]'s announcement of the Shaft Car Part showcases their commitment to innovation and customer satisfaction. With its advanced design, superior performance, and universal compatibility, it is set to significantly impact the automotive industry. As car owners strive to optimize their driving experience, [Company Name] continues to be the go-to destination for cutting-edge automotive solutions.

Important Front End Car Parts You Need for Optimal Performance

Title: Leading Innovation in the Front-End Car Parts IndustryIntroduction:The automotive industry is continuously evolving, driven by technological advancements and an increasing focus on enhancing safety and efficiency. One company that has consistently led this charge is Front End Car Parts (name omitted), a trailblazer in manufacturing cutting-edge front-end car parts. With a commitment to innovation, quality, and customer satisfaction, Front End Car Parts has firmly established itself as a trusted and reliable partner for automobile manufacturers worldwide.1. Pioneering the Front-End Car Parts Industry:Front End Car Parts (name omitted) has revolutionized the front-end car parts industry by consistently introducing innovative solutions. By utilizing advanced manufacturing techniques, they have been able to develop top-of-the-line components that optimize vehicle performance, enhance safety, and improve fuel efficiency. Their commitment to research and development has allowed them to stay ahead of the curve and meet the ever-changing demands of the automotive industry.2. Meeting Stringent Quality Standards:Front End Car Parts (name omitted) understands the critical importance of maintaining stringent quality control measures throughout the manufacturing process. Every part produced undergoes rigorous testing to ensure compliance with international safety standards. By prioritizing quality, the company has earned the trust of major automobile manufacturers globally, cementing its position as an industry leader.3. Innovative Product Range:Front End Car Parts (name omitted) prides itself on offering a diverse range of front-end car parts, catering to all customer requirements. From radiator supports, fenders, and bumper reinforcements to headlights, grilles, and hoods, their product lineup covers an extensive variety of components. Each product is designed to seamlessly integrate with different automobile models, guaranteeing a precise fit and optimum performance.4. Sustainable and Environmentally Conscious Manufacturing:Environmental sustainability is a core value at Front End Car Parts (name omitted). The company proactively implements eco-friendly practices throughout its manufacturing process, ensuring minimal impact on the environment. By utilizing energy-efficient technologies and recycling materials, they aim to reduce their carbon footprint and contribute to a greener future.5. Strong Global Presence:Front End Car Parts (name omitted) boasts a strong global presence, with distribution networks spanning several continents. Their commitment to establishing long-term partnerships and delivering unmatched customer service has garnered them a loyal customer base. Whether it's supplying front-end car parts to renowned auto manufacturers or catering to individual customers, their dedication to excellence remains unwavering.6. Continuous Expansion and Growth:Recognizing the dynamic nature of the automotive industry, Front End Car Parts (name omitted) constantly strives to expand and diversify its capabilities. By investing in state-of-the-art infrastructure and fostering collaborations with industry-leading experts, they remain at the forefront of innovation. Their tireless pursuit of growth ensures that customers can rely on them for the latest advancements in front-end car parts.7. Commitment to Customer Satisfaction:At Front End Car Parts (name omitted), customer satisfaction is paramount. The company's highly skilled and knowledgeable team works closely with clients to understand their unique requirements and provide personalized solutions. By maintaining open lines of communication and offering exceptional after-sales support, they ensure a seamless and hassle-free experience for their customers at every stage.Conclusion:Front End Car Parts (name omitted) has undoubtedly emerged as a frontrunner in the front-end car parts industry, offering innovative solutions, uncompromising quality, and exceptional customer service. With a steadfast commitment to innovation and sustainability, the company continues to shape the future of automotive engineering. As the automotive industry evolves, Front End Car Parts (name omitted) stands poised to meet the ever-growing demands by consistently delivering superior front-end car parts to drive the automobile industry towards a safer and more efficient future.

How Aluminum Pressure Die Casting Has Revolutionized Manufacturing

Title: Advancements in Aluminium Pressure Die Casting Revolutionize Manufacturing ProcessIntroduction:In today's rapidly evolving manufacturing landscape, technological advancements have played a pivotal role in enhancing efficiency and producing quality products. One such innovation that is revolutionizing the industry is Aluminium Pressure Die Casting. This article will explore the recent developments in this field and detail the impact it has had on various industries.Aluminium Pressure Die Casting: A Game-Changer in ManufacturingAluminium Pressure Die Casting is a process that involves injecting molten aluminium into a steel mold (or die) under high pressure. The ability to cast complex shapes with exceptional precision has made this manufacturing technique increasingly popular across various sectors. With the capacity to produce high-quality components with tight tolerances, the process has proven to be cost-effective whilst ensuring durability and structural integrity.Aluminium Pressure Die Casting in the Automotive IndustryThe automotive industry has greatly benefited from the advances in Aluminium Pressure Die Casting. As lightweighting becomes an increasingly important factor in vehicle design, aluminium castings have gained significant traction. These castings not only reduce overall weight but also improve fuel efficiency and enhance performance. The process allows manufacturers to create intricate designs with minimal assembly required, resulting in faster production cycles and cost savings.The Aerospace Sector Soars with Aluminium Pressure Die CastingSimilarly, the aerospace sector has embraced Aluminium Pressure Die Casting due to its numerous advantages. With the demand for fuel-efficient and lighter aircraft, aluminium castings have become critical components. The process allows for intricate and robust designs, ensuring safety and performance in extreme conditions. Additionally, the lightweight nature of aluminium results in reduced fuel consumption and lower emissions, making it an environmentally sustainable choice.Aluminium Pressure Die Casting in the Electronics IndustryIn the electronics industry, there is an ongoing need for lightweight and compact components. Aluminium Pressure Die Casting has gained prominence in this sector due to its ability to produce high-quality, intricately designed parts with excellent thermal conductivity. The process facilitates the creation of heat sinks, connectors, and other crucial components for electronic devices. With the ever-expanding market for smartphones, tablets, and other portable devices, Aluminium Pressure Die Casting has become indispensable in meeting the industry's demands.Advancements in Technological CapabilitiesTo keep up with the evolving needs of various industries, continuous advancements in Aluminium Pressure Die Casting technology have been made. The introduction of computer-aided design (CAD) software has significantly contributed to the improvement of mold design and casting accuracy. Simulation tools have also been developed to analyze thermal stresses and optimize material flow, ensuring manufacturability and minimizing defects. As a result, the process has become more efficient, cost-effective, and environmentally friendly.ConclusionAluminium Pressure Die Casting has emerged as a game-changing manufacturing process across industries such as automotive, aerospace, and electronics. With its ability to create intricate yet robust components, the process has revolutionized the way manufacturers produce parts. The lightweight nature of aluminium and its superior thermal conductivity further contribute to its widespread adoption. As technology continues to advance, it is anticipated that Aluminium Pressure Die Casting will continue to evolve, enabling manufacturers to meet the demands for efficiency, durability, and cost-effectiveness in the manufacturing sector.

Exploring the Advantages and Applications of Ferrous Metal Casting

Title: Leading Ferrous Metal Casting Company Sets New Industry Standards with Cutting-Edge InnovationsIntroduction:Renowned for its pioneering efforts in ferrous metal casting, a top industry player has now revolutionized the field with groundbreaking innovations. Backed by years of expertise and commitment to excellence, this leading company has successfully established itself as a frontrunner in the global ferrous metal casting market. By consistently pushing the boundaries of technology and introducing state-of-the-art solutions, their latest advancements are set to redefine industry standards.I. Company Background and History:{Company name} is a prominent player in the ferrous metal casting sector, with a rich legacy spanning several decades. Initially founded as a small manufacturing unit, the company quickly gained recognition for its unparalleled passion for perfection. By consistently delivering superior products and unrivaled service, {Company name} rapidly expanded its operations, cementing its position as a trusted, innovative industry leader.II. Cutting-Edge Innovations:1. Advanced Casting Technologies:{Company name} has adopted cutting-edge casting technologies to enhance product quality, productivity, and efficiency. By leveraging automated molding techniques, the company ensures consistent results while minimizing defects and reducing production time. Furthermore, advanced computer-aided design (CAD) software enables precise component modeling and customization, ensuring optimal performance.2. Sustainable Practices:Recognizing the importance of environmental preservation, {Company name} has integrated sustainable practices into its operations. The company utilizes energy-efficient furnaces, minimizing carbon emissions while maintaining casting integrity. Additionally, a robust waste management system ensures responsible disposal and recycling of casting by-products, minimizing ecological impact and promoting a greener future.3. Metallurgical Expertise:{Company name}'s team of highly skilled metallurgists brings a wealth of knowledge and experience to the table. By conducting extensive research and development, the company has perfected casting techniques that provide exceptional mechanical properties, superior strength, and resistance to wear, corrosion, and heat. This expertise enables {Company name} to produce casting solutions that surpass industry standards and meet even the most demanding customer requirements.III. Application Diversification:{Company name} aims to cater to a wide array of industries, recognizing the diverse demands of a global market. Drawing from its extensive expertise, the company offers casting solutions tailored to sectors such as automotive, aerospace, defense, energy, and mining. Whether manufacturing intricate engine components or delivering heavy-duty industrial machinery parts, {Company name}'s casting expertise ensures clients receive top-quality products designed to withstand rigorous operating conditions.IV. Commitment to Quality and Certifications:{Company name} prioritizes quality assurance at every stage of the casting process. Through stringent quality control measures, the company consistently delivers products that exceed industry standards. By adhering to rigorous testing protocols, {Company name} has obtained certifications from global quality monitoring organizations, further reinforcing its commitment to delivering excellence.V. Global Reach and Customer Satisfaction:With a strong global presence, {Company name} has successfully established itself as a trusted partner for businesses worldwide. From large corporations to small and medium-sized enterprises (SMEs), their diverse customer base attests to their versatility and reliability. By building long-lasting relationships based on trust and customer satisfaction, {Company name} continues to forge ahead in an increasingly competitive market.Conclusion:As ferrous metal casting evolves in response to shifting industrial needs, {Company name} continually pushes the boundaries of innovation. By combining advanced technologies, sustainable practices, and metallurgical expertise, the company continues to deliver superior casting solutions. With a steadfast commitment to quality, global reach, and customer satisfaction, {Company name}'s pioneering efforts are laying the foundation for a new era in ferrous metal casting while setting new industry standards.

Discover the Latest Innovations in Tail Lamp Technology for Cars

[Company Name] Presents Innovative Tail Lamp for Vehicles[City, State], [Date] - [Company Name], a leading manufacturer in the automotive industry, is proud to unveil its latest innovation in vehicle lighting - the cutting-edge [Product Name].With a mission to revolutionize the way we perceive automotive lighting, [Company Name] has been at the forefront of providing high-quality and innovative lighting solutions to vehicle manufacturers worldwide. Their commitment to delivering products that blend aesthetics with superior functionality has positioned the company as a trusted name in the industry.The new [Product Name] tail lamp is a result of extensive research and development, aimed at enhancing vehicle safety and design. Equipped with state-of-the-art technology, the tail lamp offers an array of features that surpass traditional lighting solutions.One of the key highlights of the [Product Name] is its advanced wireless connectivity. Utilizing cutting-edge wireless technology, the tail lamp can communicate with the vehicle's internal system, providing real-time feedback and data. This connectivity enables the tail lamp to display important information such as turn signals, brake lights, and reverse lights, ensuring optimal safety for drivers and pedestrians.Additionally, the [Product Name] incorporates intelligent sensors that can detect ambient light conditions. This allows the tail lamp to automatically adjust its brightness, optimizing visibility without causing discomfort to oncoming vehicles. This feature is especially useful during low-light conditions, such as during sunset or in heavy rain.Furthermore, [Product Name] boasts a sleek and modern design that complements the aesthetics of any vehicle. The smooth lines and premium materials used in its construction elevate the overall look of the vehicle. With several customization options available, customers can choose from a range of color combinations to match their vehicle's style.To maintain durability and longevity, the [Product Name] tail lamp is constructed with high-quality materials resistant to scratches, UV radiation, and extreme weather conditions. This ensures that the tail lamp remains functioning optimally, even in harsh environments."The launch of our latest tail lamp is a testament to our commitment to driving innovation in the automotive industry," stated [Speaker's Name], CEO of [Company Name]. "Our team of dedicated engineers and designers has put their skills and expertise to work, creating a tail lamp that not only enhances safety but also adds a touch of elegance to vehicles."[Company Name]'s dedication to sustainability is also highlighted by the new tail lamp. By utilizing energy-efficient LED technology, the tail lamp reduces energy consumption while maintaining superior brightness and longevity. This not only benefits the environment but also reduces a vehicle's overall carbon footprint.As part of [Company Name]'s commitment to customer satisfaction, the [Product Name] tail lamp is backed by a comprehensive warranty and excellent after-sales service. Customer support representatives are readily available to address any inquiries or concerns, ensuring a hassle-free experience for customers.The release of the [Product Name] further establishes [Company Name] as a leader in the automotive lighting industry. With its blend of advanced technology, aesthetics, and durability, the tail lamp is set to become a sought-after choice among vehicle manufacturers and enthusiasts worldwide.About [Company Name]:[Company Name] is a renowned manufacturer in the automotive industry, specializing in cutting-edge lighting solutions. With a strong focus on innovation, the company delivers products that surpass industry standards in terms of functionality, design, and reliability. With a global presence, [Company Name] continues to shape the future of automotive lighting through its commitment to excellence and customer satisfaction.For more information about [Company Name] and its range of products, please visit [Company Website].Contact:[Contact Name][Title][Company Name][Phone Number][Email][Company Website]

Top Picks for High-Quality Car Parts and Accessories

[Company Name] Introduces Exciting New Line of Automotive Parts and Accessories[date]Automotive enthusiasts around the world have reason to rejoice as [Company Name], a leading player in the industry, proudly unveils its latest range of cutting-edge automotive parts and accessories. With a solid reputation for innovation, quality, and reliability, [Company Name] continues to push boundaries, catering to the diverse needs of car owners and aficionados alike.Backed by years of expertise and technological prowess, [Company Name] has gained popularity for its commitment to staying ahead of the curve. The new line of automotive parts and accessories reiterates this dedication by providing consumers with an extensive range of products that promise to enhance their overall driving experience.One of the standout features of [Company Name]'s latest offerings is its focus on harnessing the power of advanced technology. By leveraging state-of-the-art engineering techniques and optimizing functionality, the company aims to provide automotive enthusiasts with unrivaled performance and durability.The all-new range encompasses various categories, such as engine components, suspension systems, interior accessories, and exterior enhancements. Whether it is boosting horsepower, improving fuel efficiency, or enhancing aesthetics, [Company Name] seems to have considered all aspects of automotive customization.Taking pride in their extensive research and development efforts, [Company Name] recognizes the importance of keeping up with the ever-evolving needs of the market. Through meticulous testing and rigorous quality control measures, the company ensures that their products meet and exceed industry standards.In an effort to cater to the unique preferences of consumers, [Company Name] offers a comprehensive choice in terms of both style and functionality. From sleek and aerodynamic body kits to rugged and durable off-road accessories, the company aims to cater to a broad spectrum of automotive enthusiasts, filling their driving experience with excitement and satisfaction.Furthermore, [Company Name] understands that personalization is key when it comes to the automotive industry. As such, they have introduced a range of products that allow consumers to add their personal touch to their vehicles. With an array of choices in colors, finishes, and materials, car owners can now truly make their vehicle an extension of their personality.Understanding the importance of eco-friendliness, [Company Name] has also incorporated sustainable practices into its newest offerings. By integrating eco-friendly materials and designing energy-efficient components, the company emphasizes its commitment to a greener future.For car owners seeking the latest in automotive technology, [Company Name] has introduced cutting-edge smart features in its range. Through connectivity options and advanced diagnostic capabilities, consumers can now remain connected to their vehicles like never before, enhancing convenience and peace of mind on the road.[Company Name] ensures that its products are not only accessible but also backed by reliable customer service. Recognizing that automotive customization can sometimes be overwhelming, the company provides knowledgeable support staff who can assist in selecting the right products and provide expert guidance on installation.In conclusion, [Company Name] has once again demonstrated its commitment to pioneering innovation in the automotive industry. With its new line of state-of-the-art automotive parts and accessories, the company continues to redefine the boundaries of automotive customization, elevating the driving experience to new heights.With its unwavering dedication to cutting-edge technology, exceptional quality, and customer satisfaction, it is no wonder that [Company Name] remains at the forefront of the industry. Car enthusiasts around the world eagerly await the release of these exciting new products, eager to enhance their vehicles and embark on unforgettable journeys on the road ahead.

High-Quality Aluminium Casting Die for Precision Manufacturing

Aluminium Casting Die Technology Revolutionizes Manufacturing at {}In the world of manufacturing, precision and quality are paramount. With the advancement of technology, the process of aluminium casting has evolved dramatically, thanks to cutting-edge Aluminium Casting Die technology. This revolutionary technology has not only improved the quality of aluminium products but has also significantly streamlined the manufacturing process, ultimately benefiting companies like {}.Founded in 1985, {} has been a leading force in the manufacturing industry, specializing in the production of high-quality aluminium products. With a strong emphasis on innovation and quality, the company has constantly sought ways to improve its manufacturing processes and deliver the best products to its customers. The introduction of Aluminium Casting Die technology has been a game-changer for the company, enabling it to further enhance its capabilities and achieve new heights of excellence in aluminium casting.Aluminium Casting Die technology has revolutionized the manufacturing process by allowing for the production of intricate and complex aluminium parts with unmatched precision. The technology utilizes advanced die-casting techniques to create moulds with extreme accuracy, resulting in highly detailed and flawless aluminium products. This level of precision has allowed {} to expand its product offerings and cater to a wider range of industries, including automotive, aerospace, and electronics.One of the key advantages of Aluminium Casting Die technology is its ability to produce aluminium parts with consistent quality and dimensional accuracy. This not only ensures that each part meets the highest standards but also significantly reduces wastage and rework, leading to cost savings for the company. With the implementation of this technology, {} has been able to improve its manufacturing efficiency and deliver products to its customers in a more timely and cost-effective manner.Moreover, the use of Aluminium Casting Die technology has enabled {} to achieve greater design flexibility in its manufacturing processes. The technology allows for the production of complex geometries and thin-walled sections, opening up new possibilities for product innovation and customization. This has empowered {} to collaborate with its customers more closely, offering tailored solutions to meet their specific needs and requirements.In addition to its technical advantages, Aluminium Casting Die technology also aligns with {}'s commitment to sustainability. The technology promotes the use of recycled aluminium, reducing the environmental impact of the manufacturing process. By embracing this environmentally friendly approach, {} is not only contributing to a greener planet but also catering to the growing demand for sustainable products in the market.As the industry continues to evolve, {} remains at the forefront of innovation, leveraging the latest technologies to stay ahead of the competition. The integration of Aluminium Casting Die technology has not only enhanced the company's manufacturing capabilities but has also positioned it as a leader in the field of aluminium casting. With a continued focus on quality, efficiency, and sustainability, {} is poised to further elevate its position in the market and continue to provide exceptional aluminium products to its customers.In conclusion, the introduction of Aluminium Casting Die technology has been a game-changer for {} and the manufacturing industry as a whole. By embracing this cutting-edge technology, {} has been able to significantly improve its manufacturing processes, enhance product quality, and expand its offerings to a wider range of industries. As the company continues to push the boundaries of innovation, it is clear that Aluminium Casting Die technology will play a pivotal role in shaping the future of manufacturing at {} and beyond.

High-Quality Aluminum Casting Die for Industrial Applications

Aluminum Casting Die: The Backbone of Manufacturing at {}In the world of manufacturing, precision and quality are the driving forces behind successful production processes. One essential component that plays a crucial role in achieving these benchmarks is the aluminum casting die. This vital tool is utilized in the production of a wide range of products, from automotive parts to consumer goods. At {}, the use of aluminum casting dies has been instrumental in the company's success and reputation as a leading manufacturer in the industry.With a focus on innovation and cutting-edge technology, {} has consistently pushed the boundaries of what is possible in the manufacturing sector. The company has invested heavily in state-of-the-art machinery and equipment, including advanced aluminum casting dies, to ensure that their products meet the highest standards of quality and precision.The aluminum casting die is a specialized tool that is used to create complex and intricate parts through the process of aluminum die casting. This method involves injecting molten aluminum into the die under high pressure, allowing it to solidify and take the shape of the mold. The result is a finished product that exhibits exceptional dimensional accuracy and surface finish, making it ideal for a wide range of applications.One of the key advantages of using aluminum casting dies is the ability to produce high-quality parts at a rapid pace. This increased efficiency allows {} to fulfill large orders in a timely manner, meeting the demands of their clients and maintaining a competitive edge in the market. Furthermore, the durability and longevity of aluminum casting dies ensure that they can withstand the rigors of high-volume production, making them a cost-effective solution for manufacturing operations.The expertise and skill of {}'s team of engineers and technicians are evident in the meticulous design and construction of their aluminum casting dies. Each die is customized to meet the specific requirements of the product being manufactured, ensuring that every detail is precision-engineered to exact specifications. This attention to detail is a testament to {}'s commitment to delivering superior products that exceed the expectations of their customers.In addition to their commitment to quality, {} also places a strong emphasis on sustainability and environmental responsibility. Aluminum casting is a highly efficient and recyclable process, making it an eco-friendly choice for manufacturing. By utilizing aluminum casting dies, {} is able to minimize waste and reduce their environmental impact, aligning with their dedication to corporate social responsibility and sustainable practices.Looking ahead, {} continues to explore new opportunities for advancement in the realm of aluminum casting die technology. By staying at the forefront of industry trends and developments, the company is poised to further enhance their capabilities and expand their offerings to meet the evolving needs of their customers.In conclusion, aluminum casting dies play a pivotal role in the manufacturing operations at {}. The company's investment in cutting-edge technology and unwavering dedication to quality has positioned them as a leader in the industry. With a focus on innovation, sustainability, and customer satisfaction, {} is well-positioned to continue delivering excellence in the realm of aluminum die casting for years to come.

Top Quality Cold Cast Steel for Industrial Applications

Cold Cast Steel, a leading steel manufacturing company, has recently announced the launch of their new and innovative steel product that promises to revolutionize the industry. The company has been a pioneer in the steel manufacturing sector for over two decades and is known for its high-quality products and cutting-edge technology.Cold Cast Steel has always been at the forefront of technological advancements and has continuously strived to deliver products that exceed customer expectations. The company's commitment to innovation and quality has positioned them as a trusted name in the industry.The newly launched steel product is a result of extensive research and development, and is set to offer a wide range of benefits to customers across various sectors. The product is designed to be incredibly strong and durable, making it ideal for use in construction, automotive, and industrial applications. Its unique composition and manufacturing process give it an edge over traditional steel products, offering superior performance and longevity.In addition to its exceptional strength, the new steel product is also highly resistant to corrosion, abrasion, and wear, making it an ideal choice for outdoor and high-traffic environments. Its versatility and durability make it a standout option for engineers, architects, and manufacturers looking for a reliable and long-lasting material for their projects.Cold Cast Steel's dedication to sustainability and environmental responsibility is evident in the production of this new steel product. The company has implemented state-of-the-art technology and processes to minimize waste and reduce their carbon footprint, ensuring that their products are not only of the highest quality but also environmentally friendly."We are thrilled to introduce our latest steel product to the market," said [Company Representative]. "We have put in a tremendous amount of effort and resources into developing a product that not only meets but exceeds industry standards. This new steel product is a testament to our commitment to innovation and our ongoing pursuit of excellence in everything we do."As a company that prides itself on customer satisfaction, Cold Cast Steel is dedicated to providing unparalleled service and support to its clients. Their team of experienced professionals is readily available to assist customers in choosing the right steel products for their specific needs and requirements, ensuring that they receive the best solutions for their projects.Whether it's a small-scale construction project or a large industrial undertaking, Cold Cast Steel's new steel product is set to make a significant impact in the industry. With its exceptional strength, durability, and environmental sustainability, it is poised to become a top choice for customers seeking the best quality steel for their applications.Cold Cast Steel's commitment to excellence, innovation, and customer satisfaction has solidified its reputation as a leader in the steel manufacturing sector. With the launch of their new steel product, the company is once again proving that they are at the forefront of advancements in the industry, and are dedicated to providing the best products and service to their customers.In conclusion, Cold Cast Steel's new steel product is a game-changer for the industry, and is set to raise the bar for quality and performance. As the company continues to push the boundaries of what is possible in steel manufacturing, customers can expect nothing less than the best from Cold Cast Steel. With their unwavering dedication to excellence, it's clear that the company is on a path towards continued success and innovation in the years to come.

High-Quality Duplex Casting: A Breakthrough in Manufacturing Technology

Super Duplex Casting: The Next Breakthrough in Metal Casting TechnologyIn the ever-evolving world of metal casting technology, a new advancement has taken the industry by storm - Super Duplex Casting. This cutting-edge method of casting has revolutionized the way metal components are produced, offering unparalleled strength, corrosion resistance, and durability. With the rise of demand for high-performance materials across various industries, Super Duplex Casting is set to become the go-to solution for manufacturing complex and critical parts.Super Duplex Casting is a process that involves the use of a special alloy that combines the properties of both austenitic and ferritic stainless steels. This unique combination results in a material that boasts exceptional strength and corrosion resistance, making it ideal for applications in harsh and corrosive environments. The superior mechanical properties of Super Duplex Casting make it an excellent choice for a wide range of industries, including oil and gas, chemical processing, and marine engineering.One of the leading proponents of Super Duplex Casting is {Company Name}, a renowned manufacturer and supplier of metal components for various industrial sectors. With a solid reputation for delivering high-quality products and innovative solutions, {Company Name} has been at the forefront of promoting Super Duplex Casting as a game-changer in the industry. Their state-of-the-art facilities and advanced manufacturing techniques have positioned them as a key player in the adoption and implementation of this groundbreaking technology.{Company Name} has invested heavily in research and development to optimize the Super Duplex Casting process, ensuring that their clients receive products of the highest quality. By leveraging their expertise and technical know-how, the company has been able to offer a wide range of Super Duplex Casting solutions tailored to meet the specific requirements of their customers. From complex geometries to stringent material specifications, {Company Name} has demonstrated a remarkable ability to produce superior components using this advanced casting method.The benefits of Super Duplex Casting are undeniable, and {Company Name} is committed to maximizing its potential in a variety of applications. The superior corrosion resistance of Super Duplex Casting makes it an ideal choice for components that are exposed to aggressive and corrosive media, such as seawater, acidic solutions, and chemical substances. Its high mechanical strength and excellent fatigue resistance also make it well-suited for critical structural and load-bearing components, where reliability and durability are paramount.Moreover, Super Duplex Casting offers significant cost savings over traditional materials, as it eliminates the need for additional protective coatings and frequent maintenance. With its extended service life and minimal downtime, components manufactured using Super Duplex Casting provide a compelling value proposition for industries seeking to improve their operational efficiency and reduce total cost of ownership.{Company Name} has already made significant strides in promoting the adoption of Super Duplex Casting within the industry, collaborating with leading engineering firms and end-users to showcase the capabilities of this innovative technology. By demonstrating the performance and reliability of Super Duplex Casting in real-world applications, {Company Name} has effectively positioned itself as a trusted partner for companies looking to leverage this advanced casting method for their manufacturing needs.Looking ahead, {Company Name} is poised to further expand its capabilities in Super Duplex Casting, with plans to invest in additional resources and infrastructure to meet the growing demand for this game-changing technology. With a strong commitment to delivering excellence and innovation, {Company Name} is well-positioned to drive the widespread adoption of Super Duplex Casting and shape the future of metal casting technology.In conclusion, Super Duplex Casting represents a significant advancement in the field of metal casting, offering unparalleled strength, corrosion resistance, and durability for a wide range of industrial applications. With its exceptional properties and cost-saving benefits, this innovative technology is set to revolutionize the way metal components are manufactured and utilized across various sectors. As a leading advocate for Super Duplex Casting, {Company Name} is playing a pivotal role in accelerating its adoption and unlocking its full potential in the industry.