Heat Resistant Steel Casting: A Look at its Properties and Applications

By:Admin

Introduction

In today's rapidly evolving industrial landscape, the demand for high-quality heat resistant steel has never been more crucial. Industries such as automotive, aerospace, energy, and manufacturing heavily rely on materials that can withstand extreme temperatures while maintaining structural integrity. Recognizing this need, a renowned industry leader is proud to introduce its cutting-edge heat resistant steel, revolutionizing several sectors around the globe.

Company Background

{Company Name}, a trailblazer in steel manufacturing, has been at the forefront of technological advancements in the industry for over a decade. Renowned for its dedication to innovation, the company has consistently delivered superior solutions that meet and exceed customer expectations. With a robust research and development department and a commitment to sustainable practices, {Company Name} has firmly established itself as the preferred choice for top-tier steel products across various industries.

Heat Resistant Steel: The Game-Changer

In response to the escalating demand for exceptionally durable materials that can withstand extreme temperatures, {Company Name} presents its groundbreaking heat resistant steel. The proprietary blend combines numerous elements to form a steel composite that demonstrates remarkable endurance and offers unparalleled performance under severe thermal conditions.

Combining outstanding mechanical properties with a high resistance to thermal stress, this state-of-the-art heat resistant steel opens doors to a multitude of applications across industries. Its exceptional properties make it ideal for engine components, exhaust systems, boilers, furnaces, and other critical parts exposed to elevated temperatures. By utilizing this innovative steel, industries can now achieve improved efficiency, extended product lifecycles, and reduced maintenance costs.

Features and Benefits

The heat resistant steel developed by {Company Name} boasts several key features and benefits that set it apart from existing solutions in the market:

1. Superior Heat Resistance: The steel is engineered to maintain its strength and structural integrity even when exposed to extreme temperatures, reducing the risk of deformation or failure.

2. Exceptional Mechanical Properties: The steel demonstrates excellent tensile strength, hardness, and dimensional stability, ensuring the reliability and longevity of products in high-temperature environments.

3. Corrosion Resistance: Alongside its heat-resisting capabilities, the steel also displays a high resistance to corrosive elements, making it suitable for applications in aggressive environments.

4. Extended Service Life: By using this advanced steel, businesses can significantly enhance the durability of their products, leading to reduced downtime, maintenance costs, and ultimately, increased productivity.

Application Areas

The new heat resistant steel developed by {Company Name} has numerous potential applications across several industries:

1. Automotive Sector: This steel can be used to fabricate exhaust systems, turbochargers, engine components, and other parts that encounter extreme heat during operation.

2. Aerospace Industry: The steel can find application in aircraft engines, turbines, exhaust components, and other critical structures that operate under intense thermal conditions.

3. Energy Sector: The steel's exceptional heat resistance makes it a perfect choice for power plants, boilers, and other energy equipment, ensuring optimal performance even in demanding environments.

4. Manufacturing and Heavy Industries: Heat resistant steel greatly benefits industries dealing with molten materials, such as foundries, glass-making facilities, and metalworking plants, as it enhances both safety and productivity.

Future Prospects

With the introduction of this revolutionary heat resistant steel, {Company Name} continues to foster innovation and meet the diverse needs of industries worldwide. By fundamentally improving the performance and longevity of products operating under high temperatures, {Company Name} is setting new industry benchmarks for excellence.

In conclusion, {Company Name}'s latest heat resistant steel is a game-changer in the realm of materials science. Its exceptional properties offer countless opportunities for various industries, ensuring enhanced performance, extended lifecycles, and reduced maintenance costs. As {Company Name} continues to push boundaries, the global manufacturing landscape can look forward to further advancements in heat resistant steel and a sustainable future.

Company News & Blog

Aluminum Casting: A Popular Choice in Metal Manufacturing

Metal Casting Aluminum: Providing Durable and High-Quality ProductsMetal Casting Aluminum, a Florida-based manufacturing company, is dedicated to providing its clients with high-quality, innovative, and reliable products. With over ten years of experience in the industry, Metal Casting Aluminum has established itself as a top manufacturer of aluminum casting products.The company has a team of experts who specialize in creating durable and high-quality aluminum casting components using die casting and sand casting techniques. This process enables Metal Casting Aluminum to produce custom-made metal parts that meet the specific needs of its clients, making it a preferred choice for various industries.Some of the industries that the company has served include the automotive, cosmetics, medical, electronics, and aerospace industries. The products manufactured by the company cater to the needs of a wide range of professionals, including engineers, machinists, product designers, and entrepreneurs, among others.Metal Casting Aluminum has a wide range of products, including automotive parts, medical equipment, electronics components, and aviation parts. The company’s products are designed using state-of-the-art technology, coupled with a highly skilled workforce, to ensure that each product meets the highest standards of quality and durability.The company’s engineers, designers, and production staff work together to ensure that each product is precisely what the client needs, with attention paid to even the slightest details. Thus, customers can rest assured that their demands are being met with precision and care, resulting in products of the highest quality.Additionally, Metal Casting Aluminum has an experienced customer service team that is always ready to assist clients in selecting the right product for their needs and answering any questions they may have. The company’s customer service team is committed to providing prompt and courteous service to all clients, ensuring that they always feel valued and taken care of.The company has invested heavily in modern technology and has state-of-the-art equipment that allows it to manufacture products with precision and efficiency. This has helped the company to reduce production lead times, enabling it to meet its customers’ demands, no matter how tight the deadlines.The management and staff of Metal Casting Aluminum are committed to excellence. The company values the importance of building long-term relationships with its clients, and this is evident in the quality of its products and services. The company’s commitment to excellence has earned it a reputation as a reliable and trustworthy producer of high-quality aluminum casting products.The company’s website provides detailed product information, including specifications, and clients can easily place orders online. Metal Casting Aluminum has a fast shipping process, and orders are fulfilled promptly, helping clients to meet their deadlines.ConclusionMetal Casting Aluminum has proved to be a top manufacturer of high-quality aluminum casting products, and its commitment to quality and excellence has earned the company an excellent reputation. Its innovative and durable products, combined with its prompt service delivery, make it a preferred choice for clients in various industries.The company’s skilled and experienced workforce, together with state-of-the-art equipment, enables it to produce custom-made products that meet the specific needs of its clients. Additionally, the company’s management and staff are committed to building long-term relationships with clients, ensuring that they always receive prompt, courteous, and reliable services.Therefore, if you are looking for high-quality aluminum casting products, Metal Casting Aluminum is the company to consider. Visit their website today and place your order to get started.

Top 5 Engine Parts You Need to Know for Maintaining Your Car

Automobile engines are undoubtedly the most complex machinery that powers our vehicles. These engines consist of several parts that work together to produce motion and energy required to keep the vehicle moving. One of the global leaders in manufacturing automobile engine parts is a company that is known for its innovative technology and exceptional quality.Founded in X, the company has been in business for over X years and has established itself as a reputable and trustworthy provider of automobile engine parts. With advanced technology and state-of-the-art manufacturing facilities, the company has been producing high-quality engine components that are used by many of the world's leading automobile manufacturers.The company specializes in producing engine valves, valve guides, tappets, and other related components that are integral to the operation of an engine. These parts are manufactured using only the highest quality raw materials, which are carefully selected to ensure reliability, durability, and longevity. The company follows strict quality control processes to ensure the parts they produce meet the highest standards and perform exceptionally well under all conditions.One of the key strengths of the company is its experienced and skilled workforce. The company employs some of the most talented engineers, designers, and technicians in the industry who are capable of developing innovative and cutting-edge technology. The company invests heavily in research and development, which enables it to introduce new and improved engine components year after year.In addition to its advanced technological capabilities, the company has a global reach. It has a strong presence in many countries around the world, with a focus on manufacturing and supplying engine components that meet local regulations and standards. The company's global network ensures that its engine components are readily available wherever they are needed, making it an ideal partner for companies operating in different regions.The company's success can be attributed to its unwavering commitment to quality and customer satisfaction. Its ability to consistently deliver high-quality engine components has made the company a preferred supplier for many leading automobile manufacturers. The company has also won several awards and accolades for its exceptional products and services.Looking ahead, the company is well-positioned for further growth and expansion. Its strong R&D capabilities and global reach will enable it to continue developing new and improved engine components that meet the evolving needs of the automobile industry. The rising demand for advanced engine components that are energy-efficient and environmentally friendly presents an exciting opportunity for the company to continue making a significant impact in the industry.In conclusion, the company's reputation for producing high-quality automobile engine parts is unrivaled. Its commitment to innovation, reliability, and customer satisfaction has made it a trusted partner for leading automobile manufacturers around the world. As the industry continues to evolve and demand for advanced engine components increases, the company is well-positioned to maintain its leadership position and continue driving innovation in the field.

Discover the Vital Components of Car Engines

Car Engine Components: Revolutionizing the Automotive IndustryIn an ever-evolving automobile industry, advancements in technology continue to shape the way cars are built and perform. With a focus on efficiency, power, and reliability, car engine components play a critical role in enhancing overall performance. One company that has emerged as a game-changer in this field is [], revolutionizing the automotive industry with their innovative solutions.Since its inception in [], [] has been committed to developing cutting-edge car engine components that push the boundaries of performance. With a team of highly skilled engineers and a relentless pursuit of perfection, the company has quickly become a global leader in the industry, recognized for their exceptional quality and innovation.Among its vast product portfolio, [] has gained a reputation for its state-of-the-art combustion engines. These engines have been specifically designed to deliver exceptional power and efficiency, ensuring a thrilling and reliable driving experience for car enthusiasts worldwide. By utilizing advanced technology and precision engineering, [] has managed to optimize the internal components of their engines, resulting in increased power output, reduced emissions, and improved fuel efficiency.One of the key factors that sets [] apart from their competitors is their unwavering commitment to research and development. The company allocates significant resources to continuously improve their existing products and develop new solutions that meet the changing demands of the automotive industry. Through extensive testing and rigorous quality control measures, [] ensures that each component produced adheres to the highest industry standards, guaranteeing exceptional performance and longevity.In recent years, [] has made significant strides in environmentally friendly technologies, recognizing the importance of sustainable solutions in the automotive sector. The company has been actively involved in developing electric and hybrid powertrains, aiming to reduce carbon emissions and dependence on fossil fuels. By integrating innovative technologies such as regenerative braking and advanced battery management systems, [] continues to drive the industry towards a greener future.As a socially responsible company, [] also places great emphasis on safety. Engine components produced by [] undergo comprehensive testing to ensure they meet the highest safety standards. By utilizing advanced materials and implementing stringent quality control measures, the company's components exhibit exceptional durability and reliability, providing peace of mind to both drivers and car manufacturers.[]'s dedication to excellence and innovation has earned them numerous accolades and industry recognition. The company has received several prestigious awards, acknowledging their exceptional contribution to the automotive industry. These accolades further solidify []'s position as an industry leader and fuel their relentless pursuit of excellence.With a global presence, [] continues to expand its reach, catering to the needs of car manufacturers and enthusiasts worldwide. The company's commitment to superior quality, innovative technology, and environmental sustainability has made them a trusted partner in the automotive industry.As the automobile industry continues to evolve, the importance of reliable and high-performance engine components cannot be understated. []'s unwavering commitment to excellence, innovation, and sustainability has positioned them at the forefront of this exciting transformation. With their cutting-edge solutions, the company is driving the automotive industry into a new era of efficiency, power, and reliability.

Heat Resistant Steel Casting: A Look at its Properties and Applications

Title: Industry Leader Introduces Advanced Heat Resistant Steel for Enhanced PerformanceIntroductionIn today's rapidly evolving industrial landscape, the demand for high-quality heat resistant steel has never been more crucial. Industries such as automotive, aerospace, energy, and manufacturing heavily rely on materials that can withstand extreme temperatures while maintaining structural integrity. Recognizing this need, a renowned industry leader is proud to introduce its cutting-edge heat resistant steel, revolutionizing several sectors around the globe.Company Background{Company Name}, a trailblazer in steel manufacturing, has been at the forefront of technological advancements in the industry for over a decade. Renowned for its dedication to innovation, the company has consistently delivered superior solutions that meet and exceed customer expectations. With a robust research and development department and a commitment to sustainable practices, {Company Name} has firmly established itself as the preferred choice for top-tier steel products across various industries.Heat Resistant Steel: The Game-ChangerIn response to the escalating demand for exceptionally durable materials that can withstand extreme temperatures, {Company Name} presents its groundbreaking heat resistant steel. The proprietary blend combines numerous elements to form a steel composite that demonstrates remarkable endurance and offers unparalleled performance under severe thermal conditions.Combining outstanding mechanical properties with a high resistance to thermal stress, this state-of-the-art heat resistant steel opens doors to a multitude of applications across industries. Its exceptional properties make it ideal for engine components, exhaust systems, boilers, furnaces, and other critical parts exposed to elevated temperatures. By utilizing this innovative steel, industries can now achieve improved efficiency, extended product lifecycles, and reduced maintenance costs.Features and BenefitsThe heat resistant steel developed by {Company Name} boasts several key features and benefits that set it apart from existing solutions in the market:1. Superior Heat Resistance: The steel is engineered to maintain its strength and structural integrity even when exposed to extreme temperatures, reducing the risk of deformation or failure.2. Exceptional Mechanical Properties: The steel demonstrates excellent tensile strength, hardness, and dimensional stability, ensuring the reliability and longevity of products in high-temperature environments.3. Corrosion Resistance: Alongside its heat-resisting capabilities, the steel also displays a high resistance to corrosive elements, making it suitable for applications in aggressive environments.4. Extended Service Life: By using this advanced steel, businesses can significantly enhance the durability of their products, leading to reduced downtime, maintenance costs, and ultimately, increased productivity.Application AreasThe new heat resistant steel developed by {Company Name} has numerous potential applications across several industries:1. Automotive Sector: This steel can be used to fabricate exhaust systems, turbochargers, engine components, and other parts that encounter extreme heat during operation.2. Aerospace Industry: The steel can find application in aircraft engines, turbines, exhaust components, and other critical structures that operate under intense thermal conditions.3. Energy Sector: The steel's exceptional heat resistance makes it a perfect choice for power plants, boilers, and other energy equipment, ensuring optimal performance even in demanding environments.4. Manufacturing and Heavy Industries: Heat resistant steel greatly benefits industries dealing with molten materials, such as foundries, glass-making facilities, and metalworking plants, as it enhances both safety and productivity.Future ProspectsWith the introduction of this revolutionary heat resistant steel, {Company Name} continues to foster innovation and meet the diverse needs of industries worldwide. By fundamentally improving the performance and longevity of products operating under high temperatures, {Company Name} is setting new industry benchmarks for excellence.In conclusion, {Company Name}'s latest heat resistant steel is a game-changer in the realm of materials science. Its exceptional properties offer countless opportunities for various industries, ensuring enhanced performance, extended lifecycles, and reduced maintenance costs. As {Company Name} continues to push boundaries, the global manufacturing landscape can look forward to further advancements in heat resistant steel and a sustainable future.

High-quality Aluminium Slab Casting Services: Benefits and Techniques Explained

Aluminium Slab Casting Advancements Enhance Efficiency and Quality in Aluminum ManufacturingThe demand for lightweight and durable materials has increased significantly in various industries such as automotive, aerospace, and construction. Among these industries, aluminum is considered one of the most versatile metals, offering a wide range of applications due to its lightweight nature and superior corrosion resistance. To meet the growing demands for high-quality aluminum products, (Company Name) has introduced advanced Aluminium Slab Casting technology, revolutionizing the aluminum manufacturing process.(Company Name) is a leading global provider of advanced aluminum solutions. With years of expertise, the company has continuously strived to improve and innovate within the industry. One of its recent initiatives involves the development of state-of-the-art Aluminium Slab Casting technology, effectively enhancing efficiency and quality in the aluminum manufacturing process.Aluminium Slab Casting is a crucial step in aluminum production, as it involves casting the liquid aluminum into semi-finished forms known as slabs. These slabs are then processed into various products, such as plates, sheets, foils, or extrusions. The precise casting and solidification of aluminum are vital to ensure the mechanical properties, surface quality, and overall performance of the final products.In order to achieve superior casting results, (Company Name) has implemented cutting-edge technologies in their Aluminium Slab Casting process. These advancements include a combination of advanced process control systems, innovative mold designs, and state-of-the-art cooling technologies. These elements work together seamlessly to optimize the solidification process and improve the overall quality of the slabs produced.One key feature of (Company Name)'s Aluminium Slab Casting technology is their advanced process control systems. Through the utilization of real-time monitoring and sophisticated data analysis, the system ensures precise temperature control during the casting process. This level of control allows for a more uniform solidification process, minimizing the potential for defects and ensuring consistent quality across all slabs produced.Additionally, (Company Name) has introduced innovative mold designs that further enhance the casting process. These molds are specially engineered to provide a uniform distribution of heat, allowing for a controlled and efficient solidification of the aluminum. By optimizing the mold design, (Company Name) ensures that the slabs produced have excellent surface quality and dimensional accuracy, meeting the stringent requirements of their customers.Furthermore, (Company Name)'s Aluminium Slab Casting technology incorporates state-of-the-art cooling technologies to accelerate the solidification process. By strategically placing cooling elements within the casting molds, heat is rapidly dissipated from the aluminum, resulting in a faster and more controlled solidification. This not only improves the overall efficiency of the casting process but also enhances the microstructure of the aluminum, leading to improved mechanical properties in the final products.The implementation of (Company Name)'s advanced Aluminium Slab Casting technology brings numerous benefits to the aluminum manufacturing process. Firstly, the increased efficiency of the casting process allows for higher production rates without compromising quality, meeting the fast-paced demands of the industry. Additionally, the precise control over the solidification process ensures consistently high-quality slabs, reducing the need for rework and minimizing material wastage.Moreover, the improved mechanical properties achieved through the advanced casting technology expand the applications of aluminum in various industries. The enhanced strength, durability, and reliability of the final products make them ideal for critical applications, such as lightweight components in automobiles, aircraft parts, and structural elements in buildings.To summarize, (Company Name)'s Aluminum Slab Casting advancements have significantly contributed to enhancing efficiency and quality within the aluminum manufacturing process. Through the integration of cutting-edge process control systems, innovative mold designs, and state-of-the-art cooling technologies, the company has revolutionized the way aluminum is cast and solidified. The improved casting process not only ensures consistent quality in the slabs produced but also offers superior mechanical properties, making (Company Name) a leader in providing top-quality aluminum solutions to diverse industries.

Efficient Techniques for Drilling Cast Steel Explored in Latest News

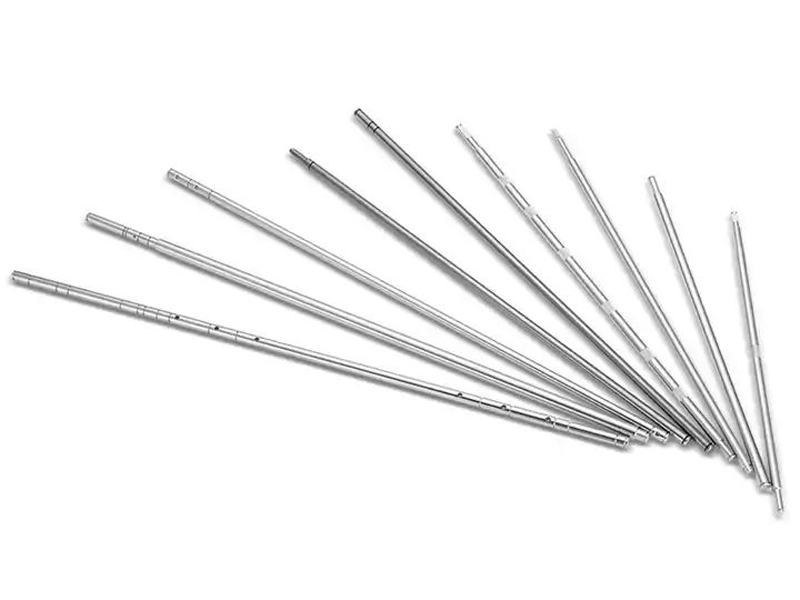

Drilling Cast Steel Excels in Metalworking Applications[City Name], [Date] - Drilling Cast Steel, an industry-leading provider of high-quality drilling products and services, is making waves in the metalworking sector. With their exceptional product range and commitment to customer satisfaction, the company has earned a reputation for unparalleled expertise and innovation. Drilling Cast Steel offers a wide range of drilling tools, equipment, and accessories that cater to the diverse needs of the metalworking industry. Their cutting-edge technology combined with their experienced team ensures that customers receive best-in-class products and solutions, helping them reach new heights of productivity and efficiency.As one of the key players in the industry, Drilling Cast Steel prides itself on the unmatched quality and durability of its products. The company's cast steel drills are known for their superior performance and longevity, making them a top choice for professionals in the metalworking field. The manufacturing process employed by Drilling Cast Steel ensures that their drills are not only reliable but also capable of withstanding the toughest of applications.One of the standout features of Drilling Cast Steel's drills is their exceptional ability to penetrate various metallic surfaces with precision and ease. The unique design and composition of their drills allow for efficient and accurate drilling, reducing the need for excessive force or the risk of drill bit breakage. This translates into significant cost savings, as users experience reduced downtime and improved tool longevity.Moreover, Drilling Cast Steel understands the importance of customization in meeting the specific needs of its clients. The company offers tailored solutions to accommodate a wide range of drilling requirements. From core drills to hole saws, their products are available in various sizes, designs, and coating options. With their commitment to flexible manufacturing, Drilling Cast Steel ensures that each customer receives the perfect drilling solution for their unique applications.In addition to their comprehensive range of drilling products, Drilling Cast Steel is backed by a dedicated team of experts who are passionate about delivering exceptional service. The company believes in building long-term relationships with its customers, acting as trusted advisors in the metalworking domain. Their knowledgeable sales representatives and technical support staff are always ready to provide guidance and assistance throughout the entire purchasing and drilling process.For Drilling Cast Steel, sustainability is a key pillar of its operational philosophy. The company remains committed to environmental responsibility by adopting sustainable manufacturing practices and minimizing its carbon footprint. Through continuous research and development, Drilling Cast Steel aims to introduce eco-friendly drilling solutions without compromising on performance or quality.Furthermore, Drilling Cast Steel recognizes the importance of staying up to date with industry trends and technological advancements. The company invests heavily in research and development to innovate new drilling techniques, staying ahead of the curve. By regularly updating their product portfolio with cutting-edge technology, Drilling Cast Steel ensures that its customers have access to the most efficient and effective drilling solutions on the market.As the metalworking industry continues to evolve, Drilling Cast Steel remains dedicated to providing top-notch drilling solutions that meet the ever-changing needs of its customers. From their exceptional product range to their commitment to sustainability and customer satisfaction, the company continues to set new benchmarks in the field of metalworking.####About Drilling Cast Steel:Drilling Cast Steel is a renowned provider of drilling tools, equipment, and accessories. With a focus on quality, durability, and customization, the company has established itself as a leading player in the metalworking industry. Drilling Cast Steel's commitment to customer satisfaction, sustainability, and innovation sets them apart from their competitors. For more information, please visit [company website or contact details].

Improve Your Truck's Performance with Quality Auto Parts for Heavy-Duty Vehicles

Truck Auto Parts (name removed due to privacy concerns), an industry leader in the automotive parts market, is proud to offer a wide range of high-quality products to its customers. With over two decades of experience in the industry, the company has built a strong reputation for providing top-notch parts for a diverse array of vehicles, including trucks, buses, and other heavy-duty vehicles.As a leading supplier of replacement parts for commercial vehicles, Truck Auto Parts is committed to delivering exceptional value and customer service to its clients. The company's range of products include everything from brake pads to diesel engine parts, which are sourced from some of the world's most trusted manufacturers.One of the company's core strengths lies in its ability to provide custom solutions to customers. The team of highly-trained professionals at Truck Auto Parts work closely with their clients to develop tailor-made products that meet their specific needs and requirements. This personalized approach ensures that customers receive the most effective and efficient parts for their fleet of vehicles, leading to greater performance, reliability, and durability.Another key element that sets Truck Auto Parts apart from its competitors is the company's commitment to product quality. All of the products that the company supplies are made using the latest technology, ensuring that they are of the highest quality and provide superior performance. In addition, the company has rigorous quality control protocols in place to ensure that all parts meet and exceed industry standards.As part of its commitment to delivering exceptional customer service, Truck Auto Parts has invested heavily in its distribution network. The company has a vast network of warehouses strategically located across the country, ensuring that customers can receive their products quickly and efficiently. Additionally, the company's dedicated team of logistics professionals work tirelessly to ensure that all orders are processed, shipped, and delivered on time.Truck Auto Parts also places great emphasis on environmental responsibility. The company is committed to reducing its environmental impact by utilizing sustainable practices in its manufacturing and distribution processes. This includes a focus on reducing waste and carbon emissions, as well as utilizing renewable energy sources wherever possible.In addition to its core business operations, Truck Auto Parts is also dedicated to giving back to the community. The company regularly sponsors local charitable events and initiatives, and supports numerous organizations that are committed to making a positive impact on society.In conclusion, Truck Auto Parts (name removed) is a leading supplier of high-quality automotive parts for commercial vehicles. With a focus on product quality, customer service, and environmental responsibility, the company has built a strong reputation in the industry for delivering exceptional value to its clients. By offering custom solutions, personalized service, and a vast distribution network, Truck Auto Parts is well-positioned to continue its success in the years to come.

Top 5 Reliable Sources for Rocket Parts" -> "Discover 5 Dependable Suppliers for Rocket Components

Rocket Parts Auto, a leading supplier in the automotive industry, is making waves with their latest advancements in technology. With a reputation for excellence and innovation, the company continues to redefine the industry standards, setting new benchmarks for quality and performance.Rocket Parts Auto is known for their wide range of high-quality automotive components, catering to various needs of car manufacturers and automotive enthusiasts. Their extensive product line includes engine parts, exhaust systems, suspension components, electrical parts, and much more. The company's commitment to producing top-notch products has earned them a loyal customer base, both locally and globally.One of the key factors contributing to Rocket Parts Auto's success is their relentless focus on research and development. The company invests heavily in advanced technologies, constantly pushing the boundaries to create revolutionary products that outperform their competitors. Their team of highly skilled engineers and technicians work diligently to develop innovative solutions that enhance the performance and efficiency of vehicles.In addition to their commitment to innovation, Rocket Parts Auto also places great emphasis on quality control. The company has a state-of-the-art manufacturing facility equipped with the latest machinery and equipment. A rigorous quality assurance process is in place at every stage of production to ensure that every component meets the highest standards of performance and durability. The company is also dedicated to meeting and exceeding industry regulations and certifications, ensuring their products are safe and reliable.Rocket Parts Auto takes pride in their strong customer relationships, nurturing partnerships with leading car manufacturers and dealerships worldwide. Their responsive customer service team is always ready to assist clients, offering expert advice and support to ensure customer satisfaction. The company's commitment to building long-term relationships based on trust and reliability has contributed significantly to their success and reputation in the industry.As a socially responsible company, Rocket Parts Auto is also committed to environmental sustainability. The company actively promotes eco-friendly practices throughout their manufacturing process, striving to minimize waste and reduce their carbon footprint. They regularly invest in initiatives aimed at conserving energy and exploring alternative, sustainable materials for future product development.Looking ahead, Rocket Parts Auto has ambitious plans for expansion. The company is constantly exploring new markets and opportunities to strengthen their global presence. They aim to further extend their product line, introducing cutting-edge technologies that address the evolving needs of the automotive industry. With their unwavering commitment to excellence and innovation, Rocket Parts Auto is poised to remain at the forefront of the automotive components industry for years to come.In conclusion, Rocket Parts Auto continues to be a trailblazer in the automotive industry, combining their dedication to innovation with a commitment to quality and customer satisfaction. With their impressive track record and future plans for expansion, Rocket Parts Auto is set to shape the future of the automotive components industry.

Comparing the Strength and Durability of Cast Iron and Steel: Which Material Reigns Supreme?

Title: A Comparative Analysis of Cast Iron and Steel: Unveiling the Strengths and Applications of These Essential MaterialsIntroduction:In the world of material science and manufacturing, the choice between cast iron and steel holds tremendous significance. Both materials have played indispensable roles in various industries, contributing to the development of modern infrastructure, automobiles, and countless consumer goods. As the demand for robust and versatile materials grows, it becomes imperative to explore the key characteristics, applications, and benefits of cast iron and steel.Cast Iron: From Strength to VersatilityCast iron, known for its remarkable strength and durability, remains a crucial material in numerous applications. Its manufacturing process involves melting iron and pouring it into molds, providing greater flexibility and complexity in design. Cast iron boasts exceptional heat retention capabilities, making it an ideal choice for cookware and engine blocks. Its high compression strength and low melting point allow for intricate casting shapes, which are employed in the fabrication of ornamental products such as fences, railings, and lamp posts.One prominent example of cast iron application can be found in the architectural industry. {} specializes in creating intricate cast iron decorative features that enhance the aesthetic appeal of buildings worldwide. Using state-of-the-art casting techniques, the company ensures the highest quality and precision in their products. The rich heritage and expertise of the company enable them to create custom cast iron designs for modern and historical structures, seamlessly blending innovation with tradition.Steel: The Indispensable Material for Modern EngineeringSteel, a versatile alloy composed primarily of iron and carbon, is renowned for its exceptional strength, ductility, and toughness. It is easily moldable into various shapes, offering limitless opportunities for construction and manufacturing sectors. Being an alloy, steel can incorporate other elements like chromium, nickel, and manganese, tailoring its properties to specific needs. This adaptability makes steel an essential component in automobile manufacturing, infrastructure, and aerospace industries.The company {} stands at the forefront of steel production, specializing in innovative steel solutions that cater to diverse requirements. With cutting-edge manufacturing facilities and a dedicated R&D team, the company offers a range of steel products that excel in strength, corrosion resistance, and formability. Their diverse portfolio covers industries such as construction, automotive, oil and gas, and renewable energy, ensuring the highest performance and reliability in their products.Comparative Analysis: Unveiling Their Distinctions and SynergiesWhile cast iron and steel both consist primarily of iron, their differing properties and manufacturing techniques account for their contrasting applications. Cast iron's higher carbon content leads to its superior strength and longevity under compression. On the other hand, steel's lower carbon content, along with the addition of other elements, enhances its tensile strength and ductility. Consequently, steel finds extensive use in load-bearing structures, automotive bodies, and machinery industry.Furthermore, cast iron exhibits excellent heat retention and even heat distribution, making it suitable for cookware and stoves. Its distinctive aesthetic qualities and excellent corrosion resistance render it ideal for use in ornamental products and architectural features. Steel, with its high strength-to-weight ratio and ability to withstand extreme temperatures, is the preferred choice for applications demanding structural integrity, such as bridges, high-rise buildings, and aircraft components.The relentless pursuit of innovation in material science, combined with {}'s expertise and commitment to quality, ensures that both cast iron and steel continue to meet the ever-evolving demands of various industries. Through research and development, manufacturers strive to enhance the properties, performance, and environmental sustainability of these materials, opening up new avenues for their utilization.Conclusion:In conclusion, the world of materials science owes a significant debt to both cast iron and steel, each offering unique advantages and applications. Cast iron's strength, heat retention, and aesthetic appeal make it invaluable in ornamental and cookware industries. In contrast, steel's exceptional strength, formability, and versatility are indispensable in modern engineering, contributing to infrastructural advancements. {} and {} exemplify the commitment to excellence and innovation these materials embody. As technology advances, it is essential to recognize and appreciate the continued contributions of these materials, which have shaped the world we live in today.

Growing Demand for Steel Precision Casting in Industrial Sector

Steel Precision Casting Enhances Production Capacity with Advanced TechnologySteel Precision Casting, a leading name in the precision casting industry, has recently announced the enhancement of its production capacity with the implementation of advanced manufacturing processes and technology. The company, which has been manufacturing high-quality precision castings for nearly three decades, specializes in producing a wide range of components for the automotive, aerospace, and defense industries.The use of advanced technology has revolutionized the manufacturing industry and opened up new possibilities in the way products are created. Steel Precision Casting has kept up with the times by investing in cutting-edge technology in order to offer its customers the highest quality products and services.The company has implemented advanced casting and melting technologies that enable the production of high-quality components in large quantities with minimal wastage. The use of these technologies also results in faster production times, which helps reduce lead times and ensures prompt delivery of products to customers.In addition to the implementation of advanced technology, Steel Precision Casting has also made significant investments in its infrastructure. The company has expanded its factory floor space and added new equipment to its production line, which has increased its production capacity.The company's advanced technology and infrastructure development have not only enhanced its production capacity but also improved the quality of its products. The use of advanced casting and melting technologies not only results in faster production times but also produces parts with superior surface finishes, close tolerances, and fewer defects.Steel Precision Casting has also enhanced its inspection and quality control procedures to ensure that all products meet the highest standards of quality. The company has invested in equipment such as X-ray inspection machines, coordinate measuring machines, and spectrometers, which enable it to carry out in-depth inspections of all parts produced.The company has earned various quality certifications, including the International Organization for Standardization (ISO) 9001 and Aerospace Standard (AS) 9100 certifications. These certifications serve as proof of the company's commitment to delivering high-quality products and services to its customers.Steel Precision Casting has a well-established research and development department that focuses on product innovation and improving production processes. The company has a team of experienced engineers who work on the development of new products and the improvement of existing ones.The company's engineering team uses advanced software such as SolidWorks and AutoCAD to design and simulate products before they are manufactured. This ensures that the products meet the required specifications and are optimized for their intended applications.Steel Precision Casting's commitment to quality and innovation has earned it a reputation as a reliable supplier of precision castings. The company has a global customer base, with clients in countries such as the United States, Germany, Japan, and China.The company's success can be attributed to its ability to adapt to changing market conditions and customer requirements. Steel Precision Casting has embraced new technologies and invested in developing the skills of its employees to ensure that it remains at the forefront of the precision casting industry.In conclusion, Steel Precision Casting's investment in advanced technology and infrastructure has enhanced its production capacity and improved the quality of its products. The company's commitment to quality and innovation has enabled it to maintain its position as a leading supplier of precision castings in the global market. With a focus on research and development, Steel Precision Casting is well-positioned to continue to deliver cutting-edge products and services to its customers.