Differences Between Cast Iron and Cast Steel: What You Need to Know

By:Admin

Founded in [year], {Company} has grown from a small workshop to a state-of-the-art facility, equipped with advanced technology and a skilled workforce. The company's success can be attributed to its relentless pursuit of improvement and a focus on meeting the ever-evolving needs of its customers.

Cast Iron Cast Steel offers a wide range of products, including cast iron, cast steel, and other customized casting products. The company's expertise lies in its ability to deliver tailor-made solutions that meet the specific requirements of its clients. Whether it's a complex industrial component or a simple agricultural tool, {Company} has the capability to produce it with precision and efficiency.

The company's manufacturing process involves the use of the latest equipment and techniques to ensure the highest quality standards. From design and pattern making to casting and finishing, every step is closely monitored to maintain consistency and uniformity in the final product. This meticulous approach has earned {Company} a reputation for excellence and reliability in the industry.

One of the key factors that sets {Company} apart from its competitors is its dedication to research and development. The company continuously invests in new technologies and explores innovative materials to enhance its product range and improve manufacturing processes. This forward-thinking approach has allowed {Company} to stay ahead of the curve and adapt to changing market demands.

In addition to its commitment to quality and innovation, {Company} places a strong emphasis on sustainability and environmental responsibility. The company adheres to strict environmental standards and strives to minimize its impact on the planet through efficient resource management and waste reduction initiatives. This conscientious approach resonates with customers who prioritize eco-friendly practices and ethical production methods.

Beyond its impressive manufacturing capabilities, {Company} is also known for its exceptional customer service. The company takes pride in building strong and lasting relationships with its clients, understanding their unique needs, and delivering personalized solutions that exceed expectations. This customer-centric approach has earned {Company} the loyalty of a diverse and loyal customer base that spans various industries.

Looking ahead, {Company} is poised to expand its presence in the global market and strengthen its position as a leading provider of casting and steel products. The company's strategic growth plans involve tapping into new market segments, diversifying its product range, and building strategic partnerships to fuel its expansion. With a solid foundation of expertise, innovation, and customer-centricity, {Company} is well-equipped to achieve its ambitious goals and continue setting new benchmarks in the industry.

In conclusion, {Company} stands out as a formidable player in the casting and steel production industry, backed by a rich legacy of excellence and a forward-looking approach. The company's commitment to quality, innovation, and customer satisfaction has made it a preferred partner for businesses across various sectors. With its unwavering dedication to improvement and a focus on sustainability, {Company} is well-positioned to achieve even greater success in the years to come.

Company News & Blog

Understanding the Properties and Uses of Tool Steel

Cast Tool Steel is a leading provider of high-quality tool steel and alloy steel products for a wide range of industrial and manufacturing applications. With a strong focus on delivering precision-engineered solutions, the company has built a solid reputation for providing reliable and durable materials that meet the stringent requirements of today’s demanding industries.The company’s dedication to producing top-notch tool steel products is evident in its state-of-the-art manufacturing facilities and its team of experienced engineers and metallurgists. By leveraging advanced technologies and innovative manufacturing processes, Cast Tool Steel is able to consistently deliver products that meet or exceed industry standards for performance and reliability.One of the key advantages of working with Cast Tool Steel is its extensive range of products, which includes a variety of tool steel and alloy steel grades, each designed to meet the specific needs of different applications. Whether it’s for plastic injection molding, die casting, or metal stamping, the company offers a comprehensive selection of materials that can be tailored to suit the unique requirements of each customer.In addition to its broad product line, Cast Tool Steel also provides custom machining and fabrication services, allowing customers to get the exact components they need to meet their specific project requirements. From precision grinding to CNC milling and turning, the company’s in-house machining capabilities enable it to deliver fully finished parts with tight tolerances and exceptional surface finishes.Furthermore, Cast Tool Steel is committed to providing exceptional customer service and technical support, ensuring that customers receive the guidance and assistance they need to make informed decisions about their material selection and processing requirements. With a team of knowledgeable and responsive professionals, the company stands ready to assist customers with everything from material selection and metallurgical consulting to troubleshooting and technical problem-solving.To maintain its position as a trusted supplier of tool steel and alloy steel products, Cast Tool Steel places a strong emphasis on quality control and strict adherence to industry standards. The company’s manufacturing processes are certified to meet ISO 9001 standards, and its materials undergo rigorous testing and inspection to ensure that they meet the highest standards for mechanical properties, microstructure, and overall performance.Looking ahead, Cast Tool Steel is poised to continue its growth and innovation in the field of tool steel and alloy steel products. With a focus on investing in new technologies, expanding its product offerings, and further enhancing its customer support capabilities, the company is well-positioned to meet the evolving needs of its customers and the rapidly changing demands of the industrial and manufacturing sectors.In conclusion, Cast Tool Steel is a trusted and reliable partner for companies seeking high-quality tool steel and alloy steel products. With its commitment to excellence, comprehensive product line, custom machining capabilities, and exceptional customer support, the company has established itself as a leader in the industry, serving a diverse range of customers with precision-engineered materials and unmatched technical expertise. Whether it’s for plastic injection molding, die casting, or metal stamping, Cast Tool Steel is the go-to source for top-notch tool steel solutions.

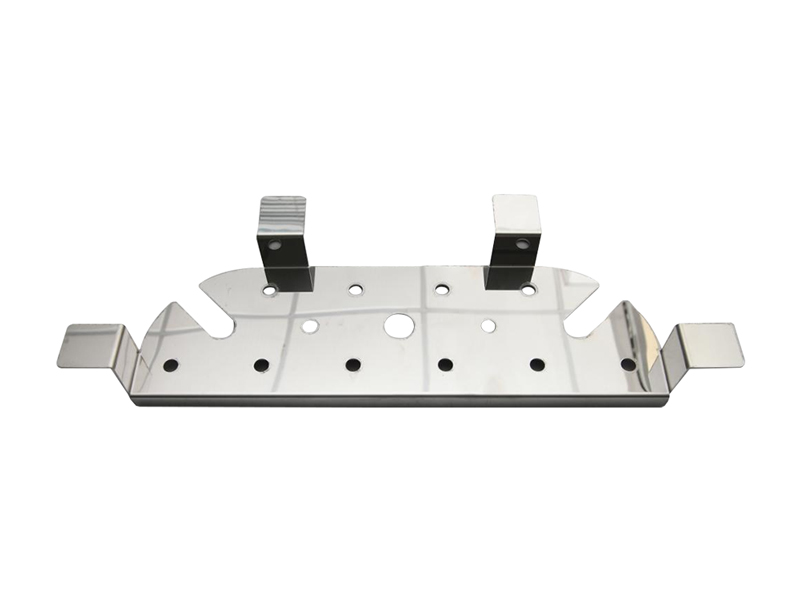

Top Quality Car Chassis Parts for Sale – Find the Best Deals Now!

{Company Name} is a leading manufacturer of high-quality car chassis parts, serving the automotive industry with top-notch products and services. The company has been in the business for over 20 years, and has earned a strong reputation for its commitment to quality, innovation, and customer satisfaction.The car chassis is one of the most important components of a vehicle, as it provides the structural support and framework for the entire car. It is essential for ensuring the safety, stability, and performance of the vehicle. {Company Name} understands the critical role that car chassis parts play in the overall functionality of a vehicle, and is dedicated to producing superior products that meet the highest industry standards.From suspension systems, steering components, and braking systems, to frame rails, sway bars, and control arms, {Company Name} offers a comprehensive range of car chassis parts, designed to meet the needs of various vehicle makes and models. The company's team of expert engineers and technicians work tirelessly to develop cutting-edge solutions that optimize the performance, efficiency, and durability of car chassis parts.One of the key strengths of {Company Name} is its state-of-the-art manufacturing facilities, which are equipped with advanced technology and machinery, enabling the company to produce precision-engineered car chassis parts with utmost accuracy and consistency. The company's production processes adhere to strict quality control measures, ensuring that every part that leaves the facility is free from defects and meets all necessary specifications.In addition to its manufacturing capabilities, {Company Name} also places a strong emphasis on research and development, continuously investing in new technologies and materials to enhance the performance and reliability of its car chassis parts. This commitment to innovation has enabled the company to stay ahead of the curve and meet the evolving needs of the automotive industry.As a customer-centric organization, {Company Name} is dedicated to providing exceptional service and support to its clients. The company works closely with customers to understand their specific requirements, offering customized solutions and technical expertise to ensure optimal performance and value. {Company Name} takes pride in its ability to build long-lasting relationships with its clients, based on trust, transparency, and mutual success.With a strong focus on sustainability and environmental responsibility, {Company Name} is committed to minimizing its ecological footprint and promoting eco-friendly practices throughout its operations. The company adheres to stringent environmental regulations and standards, and strives to implement energy-efficient and waste-reducing initiatives at every level of its business.The success of {Company Name} can be attributed to its dedicated team of professionals, who are passionate about delivering excellence in everything they do. The company's employees are its most valuable asset, and their expertise, creativity, and collaborative spirit are essential to driving the company forward.Looking ahead, {Company Name} is poised for further growth and success, as it continues to expand its product offerings, explore new markets, and strengthen its position as a leading manufacturer of car chassis parts. The company remains committed to its core values of quality, integrity, and innovation, and will continue to prioritize customer satisfaction and industry leadership in all its endeavors.In conclusion, {Company Name} is a reputable and reliable provider of car chassis parts, offering top-quality products, exceptional service, and a commitment to excellence in every aspect of its business. With its strong reputation, advanced capabilities, and customer-focused approach, the company is well-positioned to thrive in the competitive automotive industry for years to come.

Top Green Sand Options for Aluminum Casting Process

Title: Eco-friendly Solution for Aluminum Casting: Green Sand Revolutionizes Production ProcessIntroduction:In an increasingly environmentally conscious world, companies are constantly seeking sustainable alternatives to traditional manufacturing practices. One such innovation is the introduction of Green Sand for casting aluminum, a revolutionary approach that combines efficiency and environmental awareness. By harnessing this game-changing technology, companies can now optimize their production processes while significantly reducing their carbon footprint.Company Introduction: {The company} has emerged as a renowned pioneer in the manufacturing industry, offering innovative solutions tailored to the evolving needs of the market. With a firm commitment to sustainable practices, the company has been at the forefront of introducing eco-friendly alternatives. Their latest offering, Green Sand for casting aluminum, is set to revolutionize the industry by providing an efficient and environmentally responsible solution.News Article:In a major breakthrough, {Company Name} introduces a revolutionary product, Green Sand for casting aluminum, which promises to significantly improve the aluminum casting process while minimizing its impact on the environment. This eco-friendly solution is a game-changer for the industry as it combines efficiency, high-quality casting, and environmental sustainability.Traditionally, aluminum casting involves the use of sand molds to create shapes for casting. However, the traditional sand molds require a high percentage of clay and water, resulting in excessive waste and carbon emissions. {Company Name}'s Green Sand aims to address these concerns by introducing a sustainable alternative that greatly reduces environmental impact.Green Sand is a specialized mixture composed of high-quality silica sand, a small percentage of clay, and water, creating an optimal medium for molding aluminum. Unlike traditional sand molds, Green Sand can be reused multiple times, reducing the production of waste sand and minimizing the overall carbon footprint. This process aligns perfectly with current industry demands for sustainable manufacturing practices.By utilizing Green Sand, companies can experience numerous benefits, including improved production efficiency, reduced costs, and enhanced product quality. The reusable nature of Green Sand eliminates the need for constant sand replacement, reducing material costs and increasing production capacities. Additionally, the consistent quality of Green Sand molds ensures a streamlined casting process, resulting in higher precision and fewer defects in the final aluminum products.Moreover, the eco-friendly aspect of Green Sand enhances a company's corporate social responsibility profile by demonstrating their commitment to reducing environmental impact. Through the adoption of this sustainable solution, manufacturers can become leaders in their industries, attracting environmentally conscious customers who prioritize sustainability in their purchasing decisions.{Company Name} takes pride in their commitment to sustainability, and their Green Sand product is just one example of their dedication to providing innovative solutions that balance economic viability with environmental responsibility. By offering an eco-friendly alternative to traditional sand casting, {Company Name} aims to contribute significantly to reducing the manufacturing sector's carbon footprint.This breakthrough technology comes at a time when sustainability is becoming increasingly important. With environmental concerns gaining prominence across various industries, the use of Green Sand in aluminum casting represents a positive step towards a greener and more sustainable manufacturing future.In conclusion, Green Sand for casting aluminum is set to revolutionize the industry by providing an eco-friendly alternative to traditional sand molds. {Company Name}'s introduction of this technology marks a significant step forward in improving production processes while reducing environmental impact. By embracing this innovation, manufacturers can align themselves with the growing demand for sustainable practices, ensuring a brighter and more eco-conscious future for the aluminum casting industry.

Innovative Flywheel Car Part Takes the Automotive Industry by Storm

[Title]: Groundbreaking Innovation in the Automotive Industry: Revolutionary Flywheel Car Part [Subtitle]: Creating a New Era for Automotive Efficiency and Sustainability (Date) – (Location): In a groundbreaking development within the automotive industry, a cutting-edge flywheel car part has been introduced. This revolutionary technology is set to transform the way vehicles operate, paving the way towards enhanced efficiency and sustainability. This recent innovation marks a significant milestone for automotive manufacturers and consumers worldwide. Flywheels have been utilized in various industries for centuries, but their application in the automotive sector opens up a realm of possibilities for creating more efficient and environmentally friendly vehicles. By harnessing energy through rotational motion, this inventive car part aims to reduce fuel consumption and emissions, revolutionizing the way we drive. The brainchild behind this pioneering technology is a company dedicated to driving innovation within the automotive sphere. The company aims to revolutionize transportation by developing cutting-edge solutions that align with global sustainability goals. Their commitment to environmental consciousness has propelled them to create this flywheel car part, which is poised to bring about a paradigm shift in the industry. The newly developed flywheel car part employs advanced engineering principles to capture and store excess rotational energy generated by a vehicle's engine. When the car brakes or decelerates, instead of expending energy through friction, this ground-breaking component redirects it into mechanical energy, which is stored in the flywheel. This stored energy can then be utilized to power the vehicle when it accelerates or encounters an uphill climb, significantly reducing the need to rely solely on fossil fuels. One of the key advantages of this advanced flywheel technology is its ability to seamlessly integrate with existing vehicle architectures. The compact and lightweight design allows for easy installation and compatibility with various vehicle models, making it a practical solution for both new and existing cars. With its universal applicability, the flywheel car part has the potential to be a game-changer that extends beyond a single brand or model.By incorporating this innovative technology, vehicles equipped with the flywheel car part are expected to experience a considerable increase in fuel efficiency. Preliminary tests have shown reductions in fuel consumption by up to 30%, along with significant decreases in harmful emissions. This extraordinary breakthrough is a significant stride towards creating a more sustainable and eco-friendly transportation system.Apart from environmental benefits, the flywheel car part also promises enhanced driving experience for consumers. The captured energy in the flywheel ensures smoother acceleration and improved power delivery, leading to more enjoyable and controlled driving. Moreover, this technology contributes to extending the lifespan of braking systems, reducing maintenance costs and enhancing overall vehicle performance.The development and deployment of this flywheel car part serve as a stepping stone towards a future where automobiles are greener and more efficient. As automotive manufacturers continue to prioritize sustainability, this revolutionary invention will pave the way for an industry-wide transformation.Although the initial costs associated with adopting this technology may present challenges, the long-term benefits make it a promising investment. As more manufacturers integrate this innovative car part into their designs, economies of scale are expected to drive down production costs, making it an economically viable option for the mass market.In conclusion, the introduction of this groundbreaking flywheel car part is poised to revolutionize the automotive industry. With its potential to significantly improve fuel efficiency, reduce emissions, and enhance driving experience, the implementation of this technology represents a significant stride towards a sustainable future. As automotive manufacturers and consumers embrace this innovation, we can look forward to witnessing a new era of efficiency and environmental consciousness on our roads.

High-quality Aluminium Slab Casting Services: Benefits and Techniques Explained

Aluminium Slab Casting Advancements Enhance Efficiency and Quality in Aluminum ManufacturingThe demand for lightweight and durable materials has increased significantly in various industries such as automotive, aerospace, and construction. Among these industries, aluminum is considered one of the most versatile metals, offering a wide range of applications due to its lightweight nature and superior corrosion resistance. To meet the growing demands for high-quality aluminum products, (Company Name) has introduced advanced Aluminium Slab Casting technology, revolutionizing the aluminum manufacturing process.(Company Name) is a leading global provider of advanced aluminum solutions. With years of expertise, the company has continuously strived to improve and innovate within the industry. One of its recent initiatives involves the development of state-of-the-art Aluminium Slab Casting technology, effectively enhancing efficiency and quality in the aluminum manufacturing process.Aluminium Slab Casting is a crucial step in aluminum production, as it involves casting the liquid aluminum into semi-finished forms known as slabs. These slabs are then processed into various products, such as plates, sheets, foils, or extrusions. The precise casting and solidification of aluminum are vital to ensure the mechanical properties, surface quality, and overall performance of the final products.In order to achieve superior casting results, (Company Name) has implemented cutting-edge technologies in their Aluminium Slab Casting process. These advancements include a combination of advanced process control systems, innovative mold designs, and state-of-the-art cooling technologies. These elements work together seamlessly to optimize the solidification process and improve the overall quality of the slabs produced.One key feature of (Company Name)'s Aluminium Slab Casting technology is their advanced process control systems. Through the utilization of real-time monitoring and sophisticated data analysis, the system ensures precise temperature control during the casting process. This level of control allows for a more uniform solidification process, minimizing the potential for defects and ensuring consistent quality across all slabs produced.Additionally, (Company Name) has introduced innovative mold designs that further enhance the casting process. These molds are specially engineered to provide a uniform distribution of heat, allowing for a controlled and efficient solidification of the aluminum. By optimizing the mold design, (Company Name) ensures that the slabs produced have excellent surface quality and dimensional accuracy, meeting the stringent requirements of their customers.Furthermore, (Company Name)'s Aluminium Slab Casting technology incorporates state-of-the-art cooling technologies to accelerate the solidification process. By strategically placing cooling elements within the casting molds, heat is rapidly dissipated from the aluminum, resulting in a faster and more controlled solidification. This not only improves the overall efficiency of the casting process but also enhances the microstructure of the aluminum, leading to improved mechanical properties in the final products.The implementation of (Company Name)'s advanced Aluminium Slab Casting technology brings numerous benefits to the aluminum manufacturing process. Firstly, the increased efficiency of the casting process allows for higher production rates without compromising quality, meeting the fast-paced demands of the industry. Additionally, the precise control over the solidification process ensures consistently high-quality slabs, reducing the need for rework and minimizing material wastage.Moreover, the improved mechanical properties achieved through the advanced casting technology expand the applications of aluminum in various industries. The enhanced strength, durability, and reliability of the final products make them ideal for critical applications, such as lightweight components in automobiles, aircraft parts, and structural elements in buildings.To summarize, (Company Name)'s Aluminum Slab Casting advancements have significantly contributed to enhancing efficiency and quality within the aluminum manufacturing process. Through the integration of cutting-edge process control systems, innovative mold designs, and state-of-the-art cooling technologies, the company has revolutionized the way aluminum is cast and solidified. The improved casting process not only ensures consistent quality in the slabs produced but also offers superior mechanical properties, making (Company Name) a leader in providing top-quality aluminum solutions to diverse industries.

Exploring the Advantages and Applications of Ferrous Metal Casting

Title: Leading Ferrous Metal Casting Company Sets New Industry Standards with Cutting-Edge InnovationsIntroduction:Renowned for its pioneering efforts in ferrous metal casting, a top industry player has now revolutionized the field with groundbreaking innovations. Backed by years of expertise and commitment to excellence, this leading company has successfully established itself as a frontrunner in the global ferrous metal casting market. By consistently pushing the boundaries of technology and introducing state-of-the-art solutions, their latest advancements are set to redefine industry standards.I. Company Background and History:{Company name} is a prominent player in the ferrous metal casting sector, with a rich legacy spanning several decades. Initially founded as a small manufacturing unit, the company quickly gained recognition for its unparalleled passion for perfection. By consistently delivering superior products and unrivaled service, {Company name} rapidly expanded its operations, cementing its position as a trusted, innovative industry leader.II. Cutting-Edge Innovations:1. Advanced Casting Technologies:{Company name} has adopted cutting-edge casting technologies to enhance product quality, productivity, and efficiency. By leveraging automated molding techniques, the company ensures consistent results while minimizing defects and reducing production time. Furthermore, advanced computer-aided design (CAD) software enables precise component modeling and customization, ensuring optimal performance.2. Sustainable Practices:Recognizing the importance of environmental preservation, {Company name} has integrated sustainable practices into its operations. The company utilizes energy-efficient furnaces, minimizing carbon emissions while maintaining casting integrity. Additionally, a robust waste management system ensures responsible disposal and recycling of casting by-products, minimizing ecological impact and promoting a greener future.3. Metallurgical Expertise:{Company name}'s team of highly skilled metallurgists brings a wealth of knowledge and experience to the table. By conducting extensive research and development, the company has perfected casting techniques that provide exceptional mechanical properties, superior strength, and resistance to wear, corrosion, and heat. This expertise enables {Company name} to produce casting solutions that surpass industry standards and meet even the most demanding customer requirements.III. Application Diversification:{Company name} aims to cater to a wide array of industries, recognizing the diverse demands of a global market. Drawing from its extensive expertise, the company offers casting solutions tailored to sectors such as automotive, aerospace, defense, energy, and mining. Whether manufacturing intricate engine components or delivering heavy-duty industrial machinery parts, {Company name}'s casting expertise ensures clients receive top-quality products designed to withstand rigorous operating conditions.IV. Commitment to Quality and Certifications:{Company name} prioritizes quality assurance at every stage of the casting process. Through stringent quality control measures, the company consistently delivers products that exceed industry standards. By adhering to rigorous testing protocols, {Company name} has obtained certifications from global quality monitoring organizations, further reinforcing its commitment to delivering excellence.V. Global Reach and Customer Satisfaction:With a strong global presence, {Company name} has successfully established itself as a trusted partner for businesses worldwide. From large corporations to small and medium-sized enterprises (SMEs), their diverse customer base attests to their versatility and reliability. By building long-lasting relationships based on trust and customer satisfaction, {Company name} continues to forge ahead in an increasingly competitive market.Conclusion:As ferrous metal casting evolves in response to shifting industrial needs, {Company name} continually pushes the boundaries of innovation. By combining advanced technologies, sustainable practices, and metallurgical expertise, the company continues to deliver superior casting solutions. With a steadfast commitment to quality, global reach, and customer satisfaction, {Company name}'s pioneering efforts are laying the foundation for a new era in ferrous metal casting while setting new industry standards.

Durable High Chrome Steel Castings for Industrial Applications

The company is a leading manufacturer of high-quality steel castings, specializing in the production of high chrome steel castings. These castings are used in a wide range of industries, including mining, construction, and machinery manufacturing.High chrome steel castings are known for their exceptional hardness, resistance to abrasion, and high performance in demanding industrial applications. The company has been at the forefront of developing and manufacturing these superior castings for decades, and has built a strong reputation for delivering reliable and durable products to its customers.The company's production facilities are equipped with state-of-the-art technology and equipment, allowing for precise and efficient manufacturing of high chrome steel castings. The company's experienced team of engineers and technicians are dedicated to ensuring that each casting meets the highest quality standards, and that customers receive products that exceed their expectations.In addition to its focus on quality, the company is also committed to sustainability and environmentally-friendly practices. The company's manufacturing processes are designed to minimize waste and reduce environmental impact, and it works with suppliers and partners who share its commitment to sustainability.The company's high chrome steel castings are used in a wide range of applications, including in the mining industry where they are used in equipment such as crushers, grinders, and screens. These castings are essential for the efficient operation of mining operations, and the company's products are trusted by mining companies around the world to deliver outstanding performance and reliability.In the construction industry, the company's high chrome steel castings are used in a variety of equipment and machinery, including in the production of cement, concrete, and asphalt. These castings are durable and resistant to wear and tear, making them an ideal choice for demanding construction applications.The company also serves the machinery manufacturing industry, providing high chrome steel castings for use in a wide range of equipment and machinery, including in the production of heavy-duty industrial equipment and machinery. These castings are designed to withstand the rigors of heavy use and harsh operating conditions, and are trusted by manufacturers to deliver the performance and reliability they need.As a leading manufacturer of high chrome steel castings, the company is committed to providing its customers with exceptional products and exceptional service. The company works closely with its customers to understand their specific needs and requirements, and to deliver solutions that meet and exceed their expectations.The company's commitment to quality, innovation, and sustainability has made it a trusted partner for companies around the world, and its high chrome steel castings are used in a wide range of industries and applications. With a focus on continuous improvement and customer satisfaction, the company is well positioned to continue leading the industry in the manufacturing of high chrome steel castings for years to come.

Top 5 Alternator Auto Maintenance Tips You Need to Know

(Company Name) unveils cutting-edge alternator technology for enhanced vehicle performanceIn an ever-evolving automotive industry, staying ahead of the curve is crucial for any company looking to make a lasting impact. (Company Name), a leading provider of automotive parts and technology, has continued to push boundaries with their innovative solutions for vehicle performance and efficiency. The latest addition to their impressive lineup is their state-of-the-art alternator technology, designed to meet the growing demands of modern vehicles.As vehicles become more advanced, the need for reliable and efficient power generation has never been greater. This is where (Company Name)'s alternator technology comes into play, offering a range of features and capabilities that set it apart from traditional alternators. With a focus on improved energy efficiency and durability, the new alternator is poised to become a game-changer in the automotive industry.One of the key highlights of the new alternator is its advanced power generation capabilities, which are tailored to meet the power demands of modern vehicles. Whether it's powering the vehicle's electrical systems or charging the battery, the alternator is designed to deliver a consistent and reliable flow of energy, even under the most demanding conditions. This is particularly important as vehicles continue to integrate more advanced electronic and technological features.Furthermore, (Company Name)'s alternator technology is built to last, thanks to its robust design and high-quality components. With an emphasis on durability and reliability, the alternator is engineered to withstand the rigors of daily use, ensuring that it can continue to perform at its best for years to come. This not only gives vehicle owners peace of mind but also contributes to a more sustainable and eco-friendly automotive industry by reducing the need for frequent replacements.In addition to its cutting-edge performance capabilities, the new alternator is also designed with ease of installation and maintenance in mind. This is in line with (Company Name)'s commitment to providing practical and user-friendly solutions for their customers, whether they are automotive professionals or vehicle owners. By making the alternator more accessible and easier to work with, (Company Name) is setting a new standard for convenience and efficiency in the automotive parts industry.(Company Name) stands out as a leading provider of innovative automotive solutions, with a strong track record of delivering high-quality products and technology to customers across the globe. With a focus on research and development, the company continues to invest in cutting-edge technologies and engineering practices, allowing them to stay ahead of the competition and meet the ever-changing needs of the automotive market.The unveiling of the new alternator technology is a testament to (Company Name)'s ongoing commitment to innovation and excellence. By leveraging their expertise and industry knowledge, (Company Name) has once again raised the bar for vehicle performance and efficiency, offering a solution that is not only technologically advanced but also practical and reliable.As the automotive industry continues to evolve, (Company Name) remains at the forefront, driving progress and shaping the future of vehicle technology. With their new alternator technology, they are set to make a significant impact on the way vehicles generate and utilize power, further solidifying their position as a trusted and forward-thinking provider of automotive technology and solutions.In conclusion, (Company Name)'s new alternator technology represents a significant step forward in the automotive industry, offering a range of cutting-edge features and capabilities that are poised to enhance vehicle performance and efficiency. With a focus on power generation, durability, and user-friendliness, the new alternator is set to become a game-changer in the automotive parts market. As (Company Name) continues to lead the way in innovation and excellence, they are shaping the future of vehicle technology and driving progress in the industry.

Find Your Car Parts with Ease Using Online Part Checker

Car Part Checker Launches Revolutionary Automotive Platform for Car OwnersCar Part Checker, today announced the availability of its revolutionary automotive platform that enables car owners to check car parts online and find the best deals on replacement parts from reputable suppliers. This online platform is the best solution for car owners, mechanics, and auto shops who want to easily find and purchase reliable car parts.Car Part Checker is an innovative platform that can help car owners bring back their vehicle to running like new. The platform provides a user-friendly interface that allows users to search for specific car parts in seconds and compare prices from multiple sellers. The platform also provides comprehensive product information, pictures, and detailed specifications, making it easy for users to make informed decisions before making a purchase.Car Part Checker's website is well-designed, with an intuitive interface that makes it easy for users to navigate through different categories of car parts. The platform has a vast inventory of high-quality car parts that cater to different car models and brands. The platform also provides a price estimator that helps users compare prices from different suppliers.The platform offers a vast array of replacement parts, from small items such as spark plugs to larger ones, such as engines and transmissions. Car Part Checker's platform also renders repair services that provide car owners with much-needed maintenance, repair, and overhaul support when they need it the most. With Car Part Checker, car owners can rest assured that their vehicles are running smoothly and efficiently.Car Part Checker also offers a comprehensive support system to its users. The platform has a team of highly skilled and knowledgeable professionals who are available 24/7 to answer any questions concerning the site or specific product information. The platform's customer service team aims to ensure that users' experience is seamless and stress-free.One of Car Part Checker's most exciting features is its search and compare facility. The platform allows users to search for parts based on their specific car details, such as make, model, and year of manufacture. This feature makes it more accessible for car owners to get the right part for their vehicle without stress."We are excited to launch our innovative automotive platform, which provides car owners with a hassle-free solution to their car problems," said a representative from Car Part Checker. "Our platform offers a robust inventory of car parts, from engines and gearboxes to brake pads and oils. We aim to provide our users with a seamless and straightforward experience. We know how important a car is to its owner, and that's why we are committed to ensuring that every car owner can get the perfect replacement part for their vehicle."Car Part Checker's platform is highly reliable and secure. The platform uses advanced encryption technology to secure user data and ensure that online transactions are safe and secure. Users also have access to different payment options, making it easy for them to choose the payment method that suits them the most.In conclusion, Car Part Checker's innovative solution is a game-changer in the automotive industry. The platform provides a convenient and efficient way for car owners to get the right car parts at competitive prices. With its vast inventory of high-quality parts, user-friendly interface, and comprehensive support system, Car Part Checker's platform is undoubtedly the go-to place for any car owner looking for quality car parts.

Top 5 Reliable Sources for Rocket Parts" -> "Discover 5 Dependable Suppliers for Rocket Components

Rocket Parts Auto, a leading supplier in the automotive industry, is making waves with their latest advancements in technology. With a reputation for excellence and innovation, the company continues to redefine the industry standards, setting new benchmarks for quality and performance.Rocket Parts Auto is known for their wide range of high-quality automotive components, catering to various needs of car manufacturers and automotive enthusiasts. Their extensive product line includes engine parts, exhaust systems, suspension components, electrical parts, and much more. The company's commitment to producing top-notch products has earned them a loyal customer base, both locally and globally.One of the key factors contributing to Rocket Parts Auto's success is their relentless focus on research and development. The company invests heavily in advanced technologies, constantly pushing the boundaries to create revolutionary products that outperform their competitors. Their team of highly skilled engineers and technicians work diligently to develop innovative solutions that enhance the performance and efficiency of vehicles.In addition to their commitment to innovation, Rocket Parts Auto also places great emphasis on quality control. The company has a state-of-the-art manufacturing facility equipped with the latest machinery and equipment. A rigorous quality assurance process is in place at every stage of production to ensure that every component meets the highest standards of performance and durability. The company is also dedicated to meeting and exceeding industry regulations and certifications, ensuring their products are safe and reliable.Rocket Parts Auto takes pride in their strong customer relationships, nurturing partnerships with leading car manufacturers and dealerships worldwide. Their responsive customer service team is always ready to assist clients, offering expert advice and support to ensure customer satisfaction. The company's commitment to building long-term relationships based on trust and reliability has contributed significantly to their success and reputation in the industry.As a socially responsible company, Rocket Parts Auto is also committed to environmental sustainability. The company actively promotes eco-friendly practices throughout their manufacturing process, striving to minimize waste and reduce their carbon footprint. They regularly invest in initiatives aimed at conserving energy and exploring alternative, sustainable materials for future product development.Looking ahead, Rocket Parts Auto has ambitious plans for expansion. The company is constantly exploring new markets and opportunities to strengthen their global presence. They aim to further extend their product line, introducing cutting-edge technologies that address the evolving needs of the automotive industry. With their unwavering commitment to excellence and innovation, Rocket Parts Auto is poised to remain at the forefront of the automotive components industry for years to come.In conclusion, Rocket Parts Auto continues to be a trailblazer in the automotive industry, combining their dedication to innovation with a commitment to quality and customer satisfaction. With their impressive track record and future plans for expansion, Rocket Parts Auto is set to shape the future of the automotive components industry.