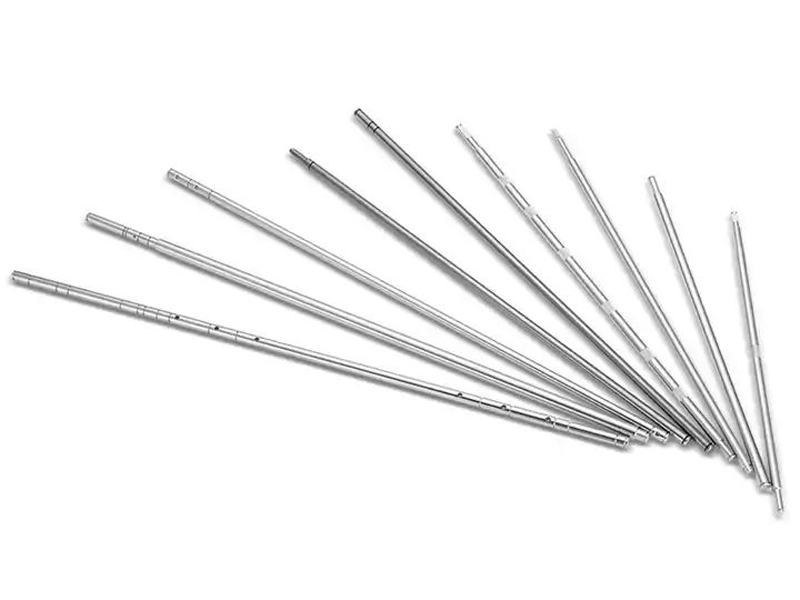

Custom High Precision Machinery Parts for Industrial Use

By:Admin

In today's rapidly evolving industrial landscape, the demand for high-quality machinery parts that are both precise and reliable has never been greater. High Precision Machinery Parts, a leading provider of cutting-edge solutions for industry needs, is at the forefront of providing top-notch components to meet this growing demand.

With a strong commitment to innovation and excellence, High Precision Machinery Parts has established itself as a trusted partner for businesses across various industries, including automotive, aerospace, and manufacturing. The company's dedication to delivering exceptional precision and quality is evident in its state-of-the-art manufacturing processes and advanced technology, which enable the production of parts that meet the most stringent standards.

One of the key factors that sets High Precision Machinery Parts apart from its competitors is its unwavering focus on precision engineering. By leveraging the latest in precision machining technology, the company is able to produce components with tolerances that far exceed industry standards. This level of precision is crucial for industries where even the smallest deviation can lead to significant operational inefficiencies and safety concerns.

In addition to its commitment to precision, High Precision Machinery Parts also places a strong emphasis on quality control. Every component undergoes rigorous testing and inspection processes to ensure that it meets the highest standards of quality and reliability. This dedication to quality assurance has earned the company a reputation for producing parts that are not only precise, but also durable and long-lasting.

Furthermore, the company's team of highly skilled engineers and technicians are adept at collaborating with clients to develop custom solutions that meet their specific needs. Whether it's a complex machined part or a specialized component, High Precision Machinery Parts has the expertise and capabilities to deliver tailored solutions that exceed expectations.

As a customer-centric organization, High Precision Machinery Parts is committed to providing exceptional service and support to its clients. The company's team of professionals is readily available to assist with any inquiries or technical challenges, ensuring that clients receive the guidance and assistance they need to achieve their goals.

High Precision Machinery Parts is also dedicated to environmental sustainability and social responsibility. The company adheres to strict environmental standards and seeks to minimize its environmental impact through sustainable manufacturing practices and responsible waste management.

With a solid track record of delivering excellence in precision machining and a commitment to continuous improvement, High Precision Machinery Parts has positioned itself as a trusted partner for businesses seeking top-quality components for their industrial needs. Whether it's a small-scale project or a large-scale production run, the company's capabilities and expertise make it a go-to source for high-precision machinery parts.

Overall, High Precision Machinery Parts's unwavering dedication to precision, quality, and customer satisfaction has earned it a reputation as a leader in the industry. With a strong focus on innovation and a commitment to excellence, the company is well-equipped to address the evolving needs of the industrial sector and continue providing cutting-edge solutions for industry needs.

Company News & Blog

Newly Developed Heat Resistant Steel Castings Offer Exceptional Durability and Corrosion Resistance

Heat Resistant Steel Casting: A Vital Component in High-Temperature ApplicationsIndustrial processes that involve high temperatures such as metal smelting, power generation, and petrochemical refining rely on a range of specialized materials to withstand adverse conditions such as intense heat, corrosion, and abrasion. Heat-resistant steel castings, also known as high-temperature alloys, are a critical component used in these applications.Heat Resistant Steel Casting is a specialized manufacturer that specializes in research, development, and production of high-quality heat-resistant steel castings. Over the years, we have established ourselves as a leading player in the industry, providing customers with customized solutions that match their unique needs.At Heat Resistant Steel Casting, quality is our top priority. Our products undergo rigorous quality checks at every stage of the manufacturing process to ensure they meet industry standards and surpass our customers' expectations. We use advanced equipment and techniques such as spectroscopy analysis, ultrasonic testing, and X-ray inspection to guarantee quality.Our range of products includes nickel-based alloy castings, cobalt-based alloy castings, and other heat-resistant steel castings that offer superior performance in high-temperature environments. These products are used in various industries such as power generation, petrochemical, aviation, nuclear energy, and marine engineering.Heat Resistant Steel Casting prides itself on its ability to provide customers with customized solutions that cater to their specific needs. Our team of highly skilled engineers work closely with clients to design castings that match their unique requirements. We use state-of-the-art software such as SolidWorks, CAD and Pro E to create 3D models and drawings that are used in the casting process.Heat Resistant Steel Casting's production process is highly efficient and cost-effective. We use advanced casting techniques such as investment casting, sand casting, and lost-foam casting to produce high-quality heat-resistant steel castings. Our production facilities include a range of state-of-the-art equipment such as electric furnaces, heat treatment furnaces, and shot blasting machines, which help us produce high-quality products with fast turnaround times.Heat Resistant Steel Casting's products are known for their exceptional performance in high-temperature environments. Our nickel-based alloy castings provide excellent resistance to thermal fatigue, oxidation, and corrosion. Our cobalt-based alloy castings are preferred for their high-temperature strength, toughness, and wear resistance.Some of our most popular products include:High-Temperature Alloy CastingsOur range of high-temperature alloy castings includes nickel-based alloys such as Inconel 601, Inconel 713, and Inconel 718, which offer excellent resistance to high-temperature oxidation and corrosion. These alloys are used in various applications such as gas turbine parts, boiler tubes, and heat exchangers.Cobalt-Based Alloy CastingsOur cobalt-based alloy castings such as Stellite 6 and Stellite 21 are renowned for their high-temperature strength, toughness, and wear resistance. These alloys are used in various applications such as valve seats, bearings, and turbine blades.Heat Resistant Steel CastingsOur heat-resistant steel castings are designed to withstand high-temperature environments without losing their strength and resistance to wear and corrosion. These products are used in various applications such as furnace parts, kiln liners, and exhaust systems.In conclusion, Heat Resistant Steel Casting is a leading manufacturer of high-quality heat-resistant steel castings. With our state-of-the-art production facilities, advanced equipment, and experienced team of engineers, we provide customers with customized solutions that match their specific needs. Our products offer exceptional performance in high-temperature environments, making them an ideal choice for various industrial applications. Contact us today to learn more about our products and services.

5 Essential Car Parts You Need to Know About for Your Vehicle

[Company Introduction] is a leading provider of automotive parts and accessories, catering to the needs of car owners and enthusiasts across the country. With a wide range of products, including engine components, electrical parts, suspension and steering systems, and more, the company has established itself as a one-stop shop for all things automotive. Their commitment to quality and customer satisfaction has made them a trusted name in the industry.Recently, the company announced an expansion of their product line, with a focus on offering a broader selection of car parts to meet the diverse needs of their customers. This move comes as a response to the increasing demand for high-quality, reliable parts that car owners can count on to keep their vehicles running smoothly.One of the key areas of focus for the company's expansion is the addition of a wider range of engine components. From fuel pumps and injectors to pistons and crankshafts, customers will now have access to an even greater selection of parts to choose from. This expanded inventory is designed to cater to a variety of vehicle makes and models, ensuring that customers can find the specific parts they need for their vehicles.In addition to the increased focus on engine components, the company is also expanding its offerings in the electrical parts category. This includes a wider selection of batteries, alternators, and ignition components, as well as an expanded range of wiring and connectors. With these additions, customers can rest assured that they will be able to find the right electrical parts for their vehicles, no matter what make or model they may have.Another area of expansion for the company is in suspension and steering systems. This includes a broader selection of shocks, struts, and springs, as well as a wider range of steering components. With these additions, customers will have more options to choose from when it comes to maintaining and upgrading their vehicle's suspension and steering systems.To support these new offerings, the company has also invested in expanding their warehouse and distribution capabilities. This will ensure that they can meet the increased demand for their products, and that customers will have access to the parts they need, when they need them. Additionally, the company has also increased their investment in research and development, to ensure that they are offering the latest and most innovative parts to their customers.With these expanded offerings and investments, [Company Introduction] is well-positioned to continue meeting the needs of their customers and solidify their position as a leading provider of automotive parts and accessories. Whether customers are looking for engine components, electrical parts, suspension and steering systems, or any other car parts, they can count on [Company Introduction] to provide high-quality, reliable products that will keep their vehicles running smoothly.In conclusion, the expansion of [Company Introduction]'s product line comes as an exciting development for car owners and enthusiasts. With a broader selection of engine components, electrical parts, and suspension and steering systems now available, customers will have more options to choose from when it comes to maintaining and upgrading their vehicles. As [Company Introduction] continues to invest in their inventory and infrastructure, customers can expect to receive the same high level of quality and service that they have come to expect from the company.

Copper Castings: Exploring the Versatile Applications of Copper in Various Industries

Title: Copper Castings: Providing Exceptional Quality for Diverse ApplicationsIntroduction:Copper Castings is a renowned company specializing in the manufacturing and supply of high-quality copper castings for various industrial applications. With a strong commitment to excellence and precision engineering, Copper Castings has established itself as a reliable and trusted provider in the industry.Body:1. Overview of Copper Castings: - Established in [year], Copper Castings has a rich history of delivering top-notch copper castings to industries worldwide. - The company has gained a solid reputation for its dedication to quality, reliability, and customer satisfaction. - With a state-of-the-art production facility, Copper Castings combines advanced technology and skilled craftsmanship to meet the diverse needs of its clients.2. Expansive Product Range: - Copper Castings offers an extensive range of copper castings, including sand castings, investment castings, centrifugal castings, and continuous castings. - These castings find applications in industries such as automotive, aerospace, electrical, plumbing, and many more. - Copper Castings prides itself on producing intricate and complex castings that meet stringent industry standards.3. Unparalleled Quality Control: - Quality is a top priority for Copper Castings, and the company adheres to rigorous quality control measures throughout the manufacturing process. - Utilizing advanced testing equipment and techniques, each casting undergoes thorough inspection to ensure dimensional accuracy and structural integrity. - Copper Castings also places emphasis on material purity, ensuring that only the highest-grade copper is used in production.4. Customization and Engineering Expertise: - Copper Castings thrives on providing customized solutions to its clients, catering to their unique specifications and requirements. - The company boasts a highly skilled team of engineers and technicians who possess extensive knowledge and expertise in copper casting techniques. - From design consultation to prototyping and final production, Copper Castings offers a seamless process that ensures customer satisfaction.5. Sustainable Manufacturing Practices: - Copper Castings is committed to sustainability and eco-friendly manufacturing practices. - The company actively reduces waste generation, minimizes energy consumption, and invests in eco-friendly technologies. - By employing environmentally conscious techniques, Copper Castings strives to minimize its carbon footprint and contribute to a greener future.6. Strong Partnerships and Global Presence: - Copper Castings has forged strong partnerships with major players in various industries, owing to its exceptional product quality and reliability. - With a global presence, the company exports its copper castings to numerous countries, catering to diverse customer requirements worldwide. - Copper Castings continuously seeks to expand its reach and establish new partnerships to further strengthen its presence in the market.Conclusion:Copper Castings continues to be at the forefront of the copper casting industry, delivering exceptional quality and innovation to its clients. With a commitment to precision engineering, customization, and sustainability, the company has successfully gained the trust of industries worldwide. As Copper Castings looks toward the future, it remains dedicated to pushing the boundaries of copper casting technology and meeting the evolving needs of its customers.

Top Green Sand Options for Aluminum Casting Process

Title: Eco-friendly Solution for Aluminum Casting: Green Sand Revolutionizes Production ProcessIntroduction:In an increasingly environmentally conscious world, companies are constantly seeking sustainable alternatives to traditional manufacturing practices. One such innovation is the introduction of Green Sand for casting aluminum, a revolutionary approach that combines efficiency and environmental awareness. By harnessing this game-changing technology, companies can now optimize their production processes while significantly reducing their carbon footprint.Company Introduction: {The company} has emerged as a renowned pioneer in the manufacturing industry, offering innovative solutions tailored to the evolving needs of the market. With a firm commitment to sustainable practices, the company has been at the forefront of introducing eco-friendly alternatives. Their latest offering, Green Sand for casting aluminum, is set to revolutionize the industry by providing an efficient and environmentally responsible solution.News Article:In a major breakthrough, {Company Name} introduces a revolutionary product, Green Sand for casting aluminum, which promises to significantly improve the aluminum casting process while minimizing its impact on the environment. This eco-friendly solution is a game-changer for the industry as it combines efficiency, high-quality casting, and environmental sustainability.Traditionally, aluminum casting involves the use of sand molds to create shapes for casting. However, the traditional sand molds require a high percentage of clay and water, resulting in excessive waste and carbon emissions. {Company Name}'s Green Sand aims to address these concerns by introducing a sustainable alternative that greatly reduces environmental impact.Green Sand is a specialized mixture composed of high-quality silica sand, a small percentage of clay, and water, creating an optimal medium for molding aluminum. Unlike traditional sand molds, Green Sand can be reused multiple times, reducing the production of waste sand and minimizing the overall carbon footprint. This process aligns perfectly with current industry demands for sustainable manufacturing practices.By utilizing Green Sand, companies can experience numerous benefits, including improved production efficiency, reduced costs, and enhanced product quality. The reusable nature of Green Sand eliminates the need for constant sand replacement, reducing material costs and increasing production capacities. Additionally, the consistent quality of Green Sand molds ensures a streamlined casting process, resulting in higher precision and fewer defects in the final aluminum products.Moreover, the eco-friendly aspect of Green Sand enhances a company's corporate social responsibility profile by demonstrating their commitment to reducing environmental impact. Through the adoption of this sustainable solution, manufacturers can become leaders in their industries, attracting environmentally conscious customers who prioritize sustainability in their purchasing decisions.{Company Name} takes pride in their commitment to sustainability, and their Green Sand product is just one example of their dedication to providing innovative solutions that balance economic viability with environmental responsibility. By offering an eco-friendly alternative to traditional sand casting, {Company Name} aims to contribute significantly to reducing the manufacturing sector's carbon footprint.This breakthrough technology comes at a time when sustainability is becoming increasingly important. With environmental concerns gaining prominence across various industries, the use of Green Sand in aluminum casting represents a positive step towards a greener and more sustainable manufacturing future.In conclusion, Green Sand for casting aluminum is set to revolutionize the industry by providing an eco-friendly alternative to traditional sand molds. {Company Name}'s introduction of this technology marks a significant step forward in improving production processes while reducing environmental impact. By embracing this innovation, manufacturers can align themselves with the growing demand for sustainable practices, ensuring a brighter and more eco-conscious future for the aluminum casting industry.

Discover the Process of Aluminium Slab Casting for Industrial Applications

Aluminium Slab Casting: Revolutionizing the IndustryAluminium slab casting is a critical process in the production of high-quality aluminium products. This process involves the solidification of molten aluminium into a form that can be further processed into various products such as sheets, plates, and extrusions. The quality of the casting process directly impacts the overall quality of the final product, making it a crucial step in the aluminium production cycle.{Company Name} is a leading player in the aluminium industry, renowned for its cutting-edge technologies and innovative solutions. The company has recently made significant advancements in the field of aluminium slab casting, revolutionizing the industry with its state-of-the-art casting technology.The company's proprietary aluminium slab casting technology is a result of years of research and development, aiming to set new benchmarks for quality, efficiency, and sustainability in the industry. By integrating advanced automation, precise control systems, and advanced material handling techniques, {Company Name} has redefined the aluminium slab casting process, addressing key challenges and unlocking new opportunities for the industry.One of the key advantages of {Company Name}'s aluminium slab casting technology is its ability to achieve superior casting quality. The advanced control systems and automation ensure precise temperature control, solidification, and mould filling, resulting in a more uniform and defect-free cast. This not only improves the overall product quality but also reduces the need for downstream processing, saving time and resources for manufacturers.Furthermore, the company's aluminium slab casting technology is designed to enhance productivity and efficiency in the production process. The advanced automation and material handling techniques enable continuous casting operations, minimizing downtime and maximizing throughput. This results in higher productivity and lower production costs, making the process more competitive and sustainable for manufacturers.In addition to quality and efficiency, {Company Name}'s aluminium slab casting technology also prioritizes sustainability and environmental responsibility. By optimizing energy use, reducing waste, and minimizing emissions, the technology aligns with the company's commitment to sustainable manufacturing practices. This not only benefits the environment but also helps manufacturers meet increasingly stringent regulatory requirements and consumer expectations for eco-friendly products.The company's aluminium slab casting technology has already gained considerable attention and traction in the industry, with several manufacturers adopting the technology to enhance their production capabilities. The positive feedback and results from these early adopters have further validated the technology's potential to transform the aluminium industry and set new standards for excellence.Moving forward, {Company Name} remains committed to advancing its aluminium slab casting technology and exploring new frontiers in the field of aluminium production. The company continues to invest in research and development, aiming to further enhance the performance, versatility, and sustainability of its casting technology. By collaborating with industry partners and stakeholders, {Company Name} is also working to establish new standards and best practices for aluminium slab casting, contributing to the continued growth and innovation of the industry.In conclusion, {Company Name}'s aluminium slab casting technology represents a significant advancement in the aluminium industry, offering new possibilities for manufacturers to achieve higher quality, efficiency, and sustainability in their production processes. As the company continues to push the boundaries of innovation and excellence, the industry can look forward to a future where aluminium slab casting sets new benchmarks for performance and value.

Revolutionizing the Industry: Cutting-Edge Components Unveiled in Latest News

Tiller Components: Revolutionizing the Manufacturing Industry with Cutting-Edge SolutionsThe manufacturing industry has always been at the forefront of innovation, constantly pushing boundaries to enhance efficiency, productivity, and overall output. In this dynamic space, companies that offer revolutionary solutions capable of addressing evolving market demands are the vanguards of progress. Tiller Components, a global leader in manufacturing capabilities, has proven its mettle by consistently delivering state-of-the-art products and services to a wide array of industries.Tiller Components has emerged as a trailblazer in the manufacturing industry, supporting businesses across diverse sectors such as automotive, aerospace, electronics, and more. With its commitment to innovation and cutting-edge technological advancements, the company has gained an enviable reputation as a reliable partner for businesses seeking high-quality components that adhere to the strictest industry standards.A significant reason for Tiller Components' success is its unwavering dedication to research and development. The company boasts an impressive team of engineers and scientists who continually explore new materials, processes, and technologies to stay ahead of the competition. By utilizing the latest manufacturing techniques, Tiller Components ensures that their products are not only at the forefront of innovation but also offer unparalleled performance, durability, and reliability.One of Tiller Components' flagship offerings is their range of precision-machined components. Leveraging state-of-the-art CNC machining technology, the company is capable of delivering highly intricate and precise components that cater to even the most demanding applications. Whether it's producing intricate automotive parts, aerospace components, or electronic connectors, Tiller Components' expertise in precision machining sets them apart from their competitors.In addition to precision machining, Tiller Components also specializes in additive manufacturing, commonly referred to as 3D printing. Additive manufacturing is a revolutionary process that enables the creation of complex geometries and customized designs, surpassing the limitations of traditional manufacturing methods. By investing in cutting-edge 3D printing technologies, Tiller Components has positioned itself as a visionary in the field, offering customers unprecedented design freedom, reduced lead times, and enhanced cost-effectiveness.Tiller Components is not just a supplier of superior-quality components; their commitment to providing holistic solutions is what truly sets them apart. The company offers comprehensive design and engineering services, working closely with their clients to understand their specific requirements and challenges. With its vast knowledge and expertise, Tiller Components assists customers in streamlining their manufacturing processes, reducing costs, and improving overall efficiency.Another aspect that distinguishes Tiller Components from its competitors is its strong emphasis on sustainability. The company recognizes the importance of environmental responsibility and actively adopts eco-friendly manufacturing practices. By leveraging innovative technologies, Tiller Components strives to minimize waste, reduce energy consumption, and optimize resource utilization at every step of the manufacturing process. In doing so, they contribute to the greater goal of achieving a greener and more sustainable future for the industry.As a global leader, Tiller Components has an extensive network of manufacturing facilities and distribution centers strategically located around the world. This ensures efficient and timely delivery of products, regardless of customer location. With a strong commitment to customer satisfaction, Tiller Components provides unparalleled support and service, enabling businesses to meet their project deadlines and objectives with ease.In conclusion, Tiller Components has firmly established itself as a pioneer in the manufacturing industry by consistently delivering innovative and advanced solutions to customers worldwide. From precision machining to additive manufacturing, they offer a comprehensive suite of capabilities that cater to the diverse requirements of numerous sectors. With their unwavering commitment to progress, environmental responsibility, and customer satisfaction, Tiller Components continues to shape the future of manufacturing, one revolutionary component at a time.

Durable Stainless Steel Casting Rings: A Long-Lasting Jewelry Option

Stainless Steel Casting Ring - A Testament to Quality, Durability, and CraftsmanshipStainless steel casting is a manufacturing process that involves pouring molten stainless steel into a mold to create a specific shape or design. The resulting products boast exceptional strength, durability, and resistance to corrosion, making them ideal for a wide range of applications.One company that has made a name for itself in the stainless steel casting industry is {company name}. With a rich history dating back to {year}, {company name} has established itself as a leading manufacturer and supplier of high-quality stainless steel casting products.The company's dedication to quality, innovation, and customer satisfaction has allowed it to thrive in the highly competitive market. Its state-of-the-art facilities and advanced manufacturing techniques enable {company name} to produce a wide variety of stainless steel casting products, including rings, jewelry, hardware, and industrial components.Among its impressive lineup of products, the stainless steel casting ring stands out as a shining example of {company name}'s commitment to excellence. Crafted with precision and attention to detail, these rings embody the perfect blend of form and function. Whether it's a simple and elegant design or an intricate and elaborate piece, each ring is a work of art that reflects the company's craftsmanship and expertise.One of the key advantages of stainless steel casting rings is their exceptional durability. Unlike traditional rings made from other materials, stainless steel casting rings are known for their ability to withstand the test of time. They are resistant to tarnishing, scratching, and fading, making them an excellent choice for everyday wear.In addition to their durability, stainless steel casting rings are also highly versatile. They can be crafted into a wide range of styles and designs, catering to a diverse array of tastes and preferences. Whether it's a sleek and modern look or a vintage-inspired design, {company name} has the capabilities to bring any vision to life.Furthermore, stainless steel casting rings are hypoallergenic, making them an ideal choice for individuals with sensitive skin. They are also easy to maintain, requiring minimal cleaning and upkeep to keep them looking as good as new.{Company name} takes great pride in its commitment to sustainability and environmental responsibility. The company utilizes eco-friendly manufacturing processes and materials, ensuring that its products have minimal impact on the environment. This dedication to sustainability has set {company name} apart in the industry, earning it a reputation as a responsible and conscientious manufacturer.With its steadfast dedication to quality, innovation, and customer satisfaction, {company name} has earned the trust and loyalty of customers around the world. Whether it's a wholesale order for a retail business or a custom design for a private client, the company's team of skilled artisans and craftsmen work tirelessly to deliver exceptional products that exceed expectations.In conclusion, stainless steel casting rings are a testament to the quality, durability, and craftsmanship that {company name} embodies. With a strong commitment to excellence and a passion for innovation, the company continues to be a driving force in the stainless steel casting industry, setting the standard for superior products and unmatched customer service. Whether it's for personal adornment or industrial applications, customers can trust {company name} to deliver top-notch stainless steel casting products that stand the test of time.

Discover the Latest Trends in Automotive Sheet Metal Stamping

Automotive Sheet Metal Stamping: Revolutionizing the Automobile IndustryThe automotive industry has always been at the forefront of technological advancements. From innovative design features to cutting-edge safety solutions, automobile manufacturers are constantly pushing the boundaries of what vehicles can achieve. One such advancement that has revolutionized the automobile industry is automotive sheet metal stamping.Sheet metal stamping is the process of creating metal parts, components, and structures by applying significant force to a metal sheet. This process not only allows for the mass production of complex and intricate metal parts but also ensures a high level of precision and consistency.In the world of automotive manufacturing, the importance of sheet metal stamping cannot be overstated. The ability to produce large quantities of complex metal parts with incredible accuracy and speed has allowed automobile manufacturers to streamline their production processes and significantly reduce costs.{} is a leading company in the automotive sheet metal stamping industry. With a rich history spanning over five decades, {} has established itself as a pioneer in the field of metal stamping and has played a crucial role in shaping the modern automobile industry.{}'s state-of-the-art facilities and cutting-edge technology have allowed them to produce a wide range of automotive components, from body panels and structural components to intricate engine parts and interior trim pieces. The company's unwavering commitment to delivering high-quality products has earned them a stellar reputation among the world's leading automobile manufacturers.One of the key factors that sets {} apart from its competitors is its relentless pursuit of innovation. The company's team of highly skilled engineers and designers are constantly pushing the boundaries of what is possible with sheet metal stamping, developing new techniques and processes that have redefined the industry standards.In addition to its commitment to innovation, {} places a strong emphasis on sustainability and environmental responsibility. The company has implemented numerous initiatives to reduce its environmental impact, from investing in energy-efficient manufacturing processes to implementing recycling and waste reduction programs.With a strong focus on customer satisfaction and a dedication to excellence, {} has become a trusted partner for some of the world's most renowned automobile manufacturers. The company's ability to consistently deliver high-quality products on time and within budget has made it an invaluable asset to the global automotive industry.As the automotive industry continues to evolve, the demand for innovative and efficient manufacturing processes will only continue to grow. Automotive sheet metal stamping, with companies like {} leading the charge, will undoubtedly play a crucial role in shaping the future of automobile manufacturing.As the industry looks towards an increasingly electrified, connected, and autonomous future, the need for lightweight yet durable components will become more pronounced than ever. Automotive sheet metal stamping, with its ability to produce lightweight, high-strength parts at scale, will be instrumental in meeting these evolving demands.In conclusion, automotive sheet metal stamping has had a profound impact on the automobile industry, revolutionizing the way vehicles are manufactured and setting new standards for efficiency, precision, and sustainability. {}'s unwavering dedication to excellence and innovation has positioned the company as a key player in the industry, and its contributions will undoubtedly continue to shape the future of automotive manufacturing for years to come.

Top Car Interior Parts to Upgrade Your Vehicle

Car Interior Parts Manufacturer {company name disguised} Continues to Expand Its Reach in the Global Market{City, Country, Date} - {Company name disguised}, a leading manufacturer of car interior parts, has been consistently expanding its reach in the global market, offering high-quality products to clients around the world. With its focus on innovation, customer service, and high-quality manufacturing processes, {company name disguised} has become a household name in the automotive industry.Founded in 2006, {company name disguised} has been working tirelessly to meet the increasing demands of the automotive industry. With its state-of-the-art manufacturing facilities and highly skilled workforce, the company produces a wide range of car interior parts, including car seats, door panels, dashboards, and steering wheels.{Company name disguised} takes pride in its commitment to innovation, constantly striving to enhance the design and functionality of its products. The company's in-house research and development team meticulously tests and refines its products to ensure they meet the highest quality standards. Through its continued efforts in research and development, {company name disguised} has been able to introduce a range of innovative products to the market, including 3D-printed car seats, heated steering wheels, and custom-designed upholstery.In addition to its commitment to innovation, {company name disguised} places a strong emphasis on customer service. The company's skilled workforce is trained to provide personalized service to clients, ensuring that their needs are met with efficiency and professionalism. By maintaining close relationships with its clients, {company name disguised} has been able to stay ahead of the competition and maintain its position as a leading manufacturer of car interior parts.With its state-of-the-art manufacturing facilities and commitment to quality and innovation, {company name disguised} has become a trusted partner for automotive manufacturers around the world. The company's products are used by some of the biggest names in the automotive industry, including BMW, Mercedes-Benz, and Audi, among others.Despite the challenges posed by the COVID-19 pandemic, {company name disguised} has continued to expand its reach in the global market. The company has recently signed several major contracts with automotive manufacturers in North America, Europe, and Asia, further strengthening its position as a leading supplier of car interior parts.Looking ahead, {company name disguised} is committed to maintaining its focus on innovation, customer service, and quality manufacturing processes. By staying at the forefront of the latest trends and technologies in the automotive industry, the company is well-positioned to continue its growth and success in the years to come.About {company name disguised}:{Company name disguised} is a leading manufacturer of car interior parts, founded in {year}. With its state-of-the-art manufacturing facilities and highly skilled workforce, the company produces a wide range of car interior parts, including car seats, door panels, dashboards, and steering wheels. The company is committed to innovation, customer service, and quality manufacturing processes, and serves clients around the world, including some of the biggest names in the automotive industry.

Ultimate Guide to Finding the Perfect Car Parts Online

Car Part Company A Acquires New Technology to Enhance Customer ExperienceCar Part Company A is proud to announce the acquisition of new technology that will revolutionize the way customers interact with their products and services. This new technology, developed by a leading software company, will be integrated into Car Part Company A's existing platform to provide customers with a seamless and enhanced experience. With this new technology, Car Part Company A aims to solidify its position as a leader in the automotive parts industry and set new standards for customer satisfaction.The new technology includes a state-of-the-art mobile app that will allow customers to easily search for and purchase car parts from their smartphones or tablets. The app will feature a user-friendly interface, advanced search capabilities, and secure payment options, making it easier than ever for customers to find the parts they need and complete their purchases. In addition, the app will also provide customers with access to real-time inventory updates, order tracking, and customer support, ensuring a smooth and hassle-free shopping experience.Car Part Company A is committed to providing its customers with the best possible experience, and this new technology is just one of the many initiatives the company has undertaken to achieve this goal. As a company that prides itself on innovation and customer satisfaction, Car Part Company A has consistently invested in cutting-edge technology and advanced solutions to improve its operations and provide the highest quality service to its customers.In addition to the new mobile app, Car Part Company A's acquisition of the new technology will also include the implementation of a sophisticated inventory management system. This system will allow Car Part Company A to monitor and track its inventory in real time, ensuring that customers have access to the parts they need when they need them. The new inventory management system will also enable Car Part Company A to optimize its supply chain and reduce lead times, leading to improved efficiency and faster delivery times for customers.Furthermore, the new technology will offer enhanced data analytics capabilities, providing Car Part Company A with valuable insights into customer behavior, preferences, and purchasing patterns. These insights will enable the company to better understand its customers and tailor its products and services to meet their specific needs. By leveraging this data, Car Part Company A aims to improve its product offerings, marketing strategies, and customer service, ultimately enhancing the overall customer experience.With the acquisition of this new technology, Car Part Company A is well-positioned to meet the evolving needs of its customers and stay ahead of the competition in the automotive parts industry. By embracing innovation and investing in advanced solutions, Car Part Company A is demonstrating its commitment to excellence and ensuring that its customers receive the best possible service.In conclusion, the acquisition of new technology by Car Part Company A represents a significant milestone for the company and its customers. By integrating this cutting-edge technology into its platform, Car Part Company A is poised to deliver an unparalleled customer experience and set new standards for the automotive parts industry. With its ongoing dedication to innovation and customer satisfaction, Car Part Company A continues to solidify its position as a leader in the industry and a trusted partner for customers seeking high-quality car parts and exceptional service.